Yoke-free stator assembly and axial permanent magnet hub type motor

A yoke stator and yoke stator technology are applied in the field of non-magnetic yoke stator components and axial permanent magnet in-wheel motors, which can solve the problems of low conversion rate, large magnetic loss, increase in size and weight of in-wheel motors, etc., and achieve conversion rate High, low loss, reducing the effect of magnetic radial diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

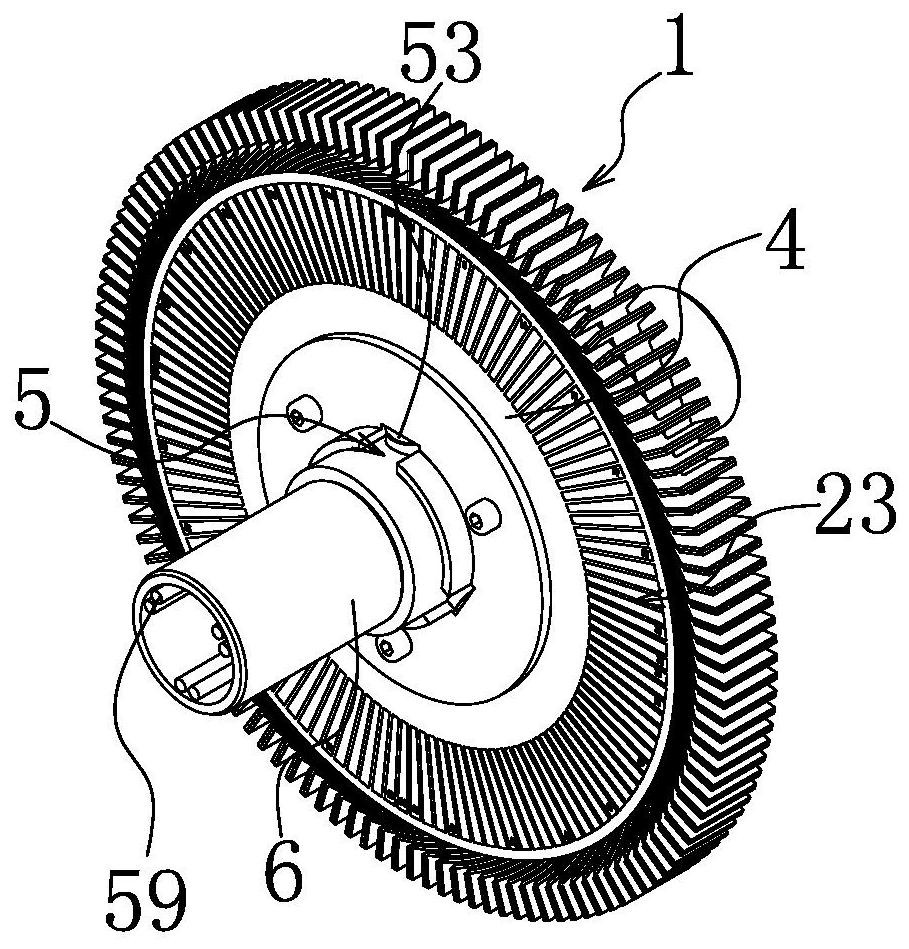

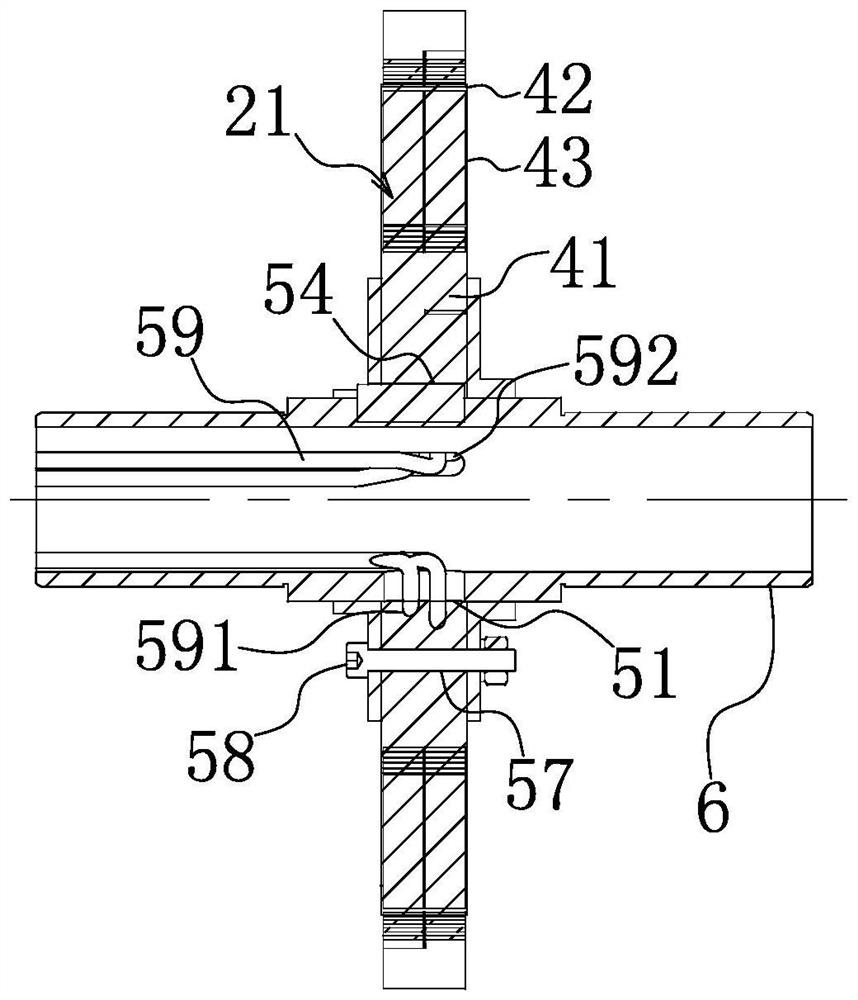

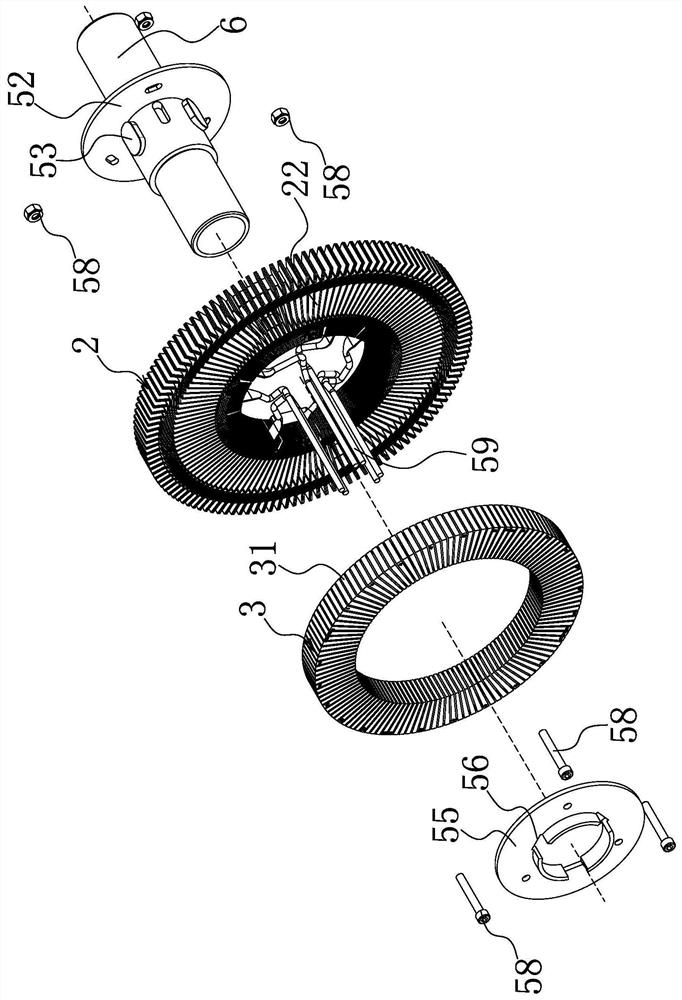

[0030] like Figure 1-3As shown, the present yokeless stator assembly includes a stator body 1 having a stator coil winding 2 and a stator iron core assembly 3. The stator coil winding 2 is a ring-shaped structure formed by a number of stator coil groups 21 distributed in the circumferential direction. The stator iron The core assembly 3 has a plurality of magnetic conductors 31 which are distributed circumferentially with the center of the stator coil winding 2 as the center and are respectively embedded between two adjacent stator coil groups 21. Preferably, the two adjacent stators here are A winding gap 22 is formed between the middle of the coil group 21 , the winding gap 22 is evenly distributed in the circumferential direction, and the magnetic conductors 31 are all sheet-shaped and are respectively embedded in the winding gap 22 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap