Rotating wheel type medicine feeding mechanism

A wheel-type drug delivery technology, applied in conveyors, slideways, transportation and packaging, etc., can solve the problems of high operating costs, rising equipment costs, large and complex, etc., to ensure the accuracy and accuracy of drug delivery, and facilitate the delivery of medicines. The effect of maintenance and use and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

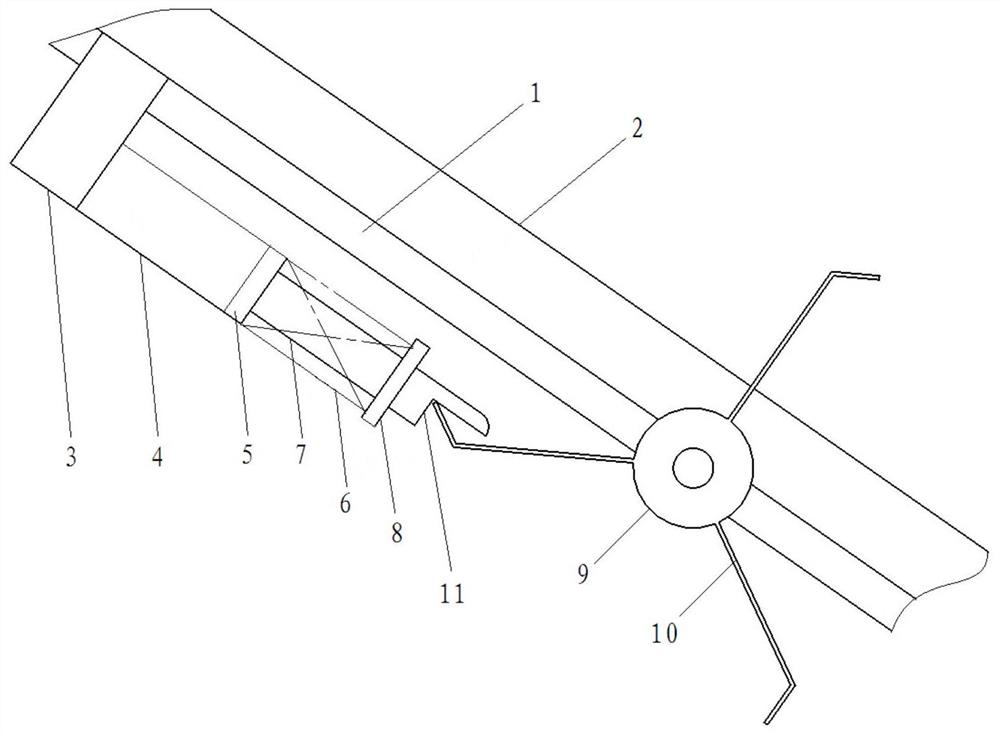

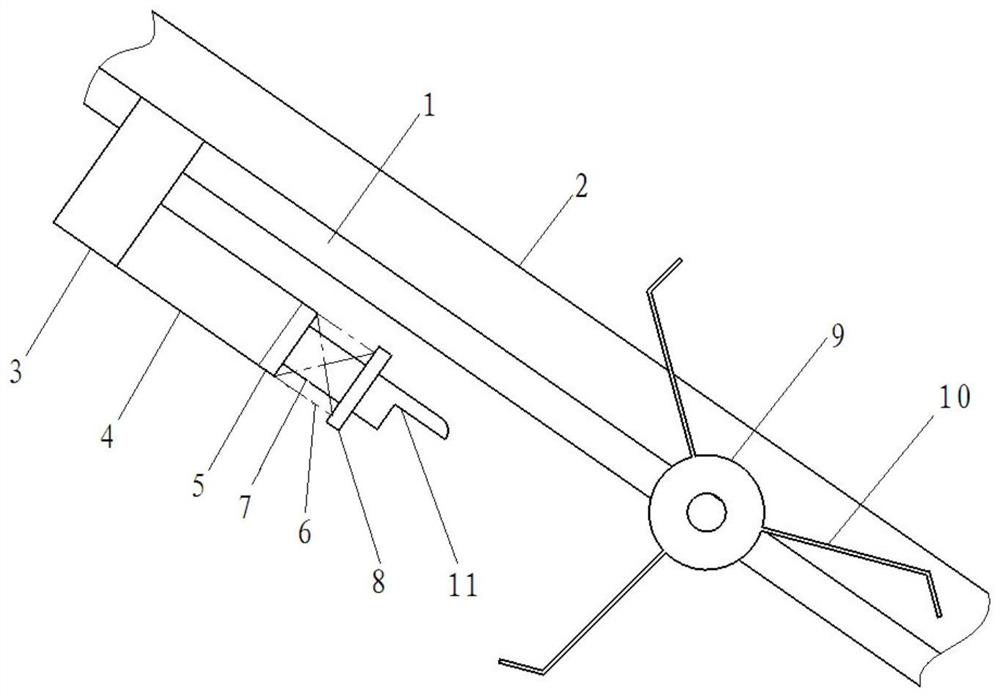

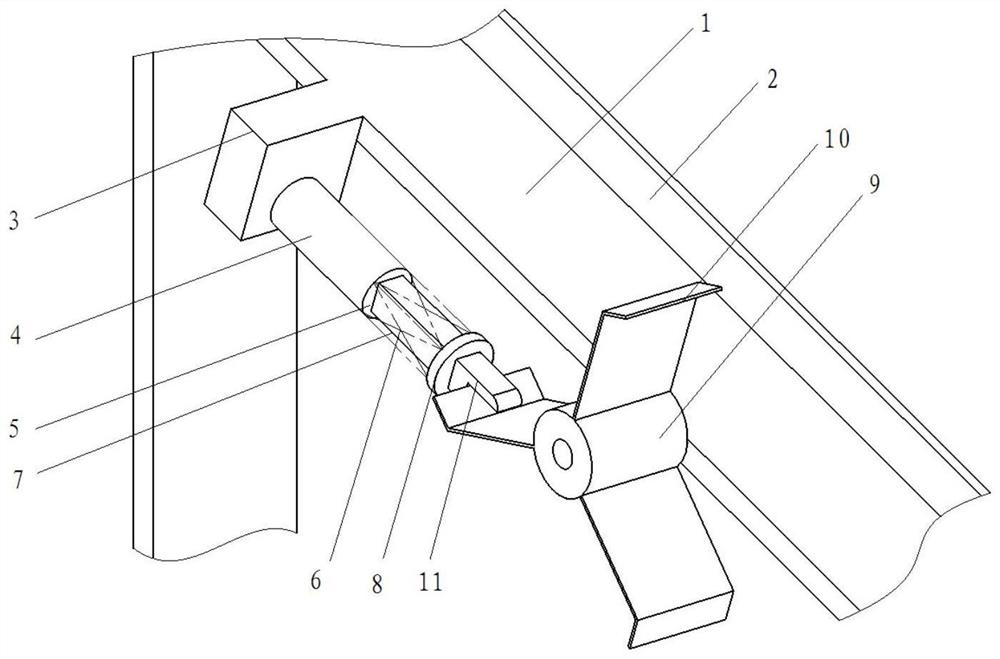

[0028] like Figures 1 to 5 As shown, the wheel-type drug delivery mechanism adopted in the present invention includes: a drug delivery track 1 fixedly connected to a through-groove landslide structure through a mechanism bracket 3 and a runner 9 with three blades 10 at the lower end of the drug delivery track 1, and The blades 10 are evenly distributed on the runner 9, and their width is smaller than the width of the channel of the medicine delivery track 1; The sleeve 4 and the electromagnet 5, the sleeve 4 is built with a guide rod 7 parallel to its axis, a spring 6 is connected between the sleeve 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap