Ballastless track base plate drainage slope closing device

A technology of ballastless track and base plate, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of low construction efficiency, affecting construction quality, difficult control of slope accuracy, etc., and achieve the effect of improving construction efficiency and ensuring slope accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

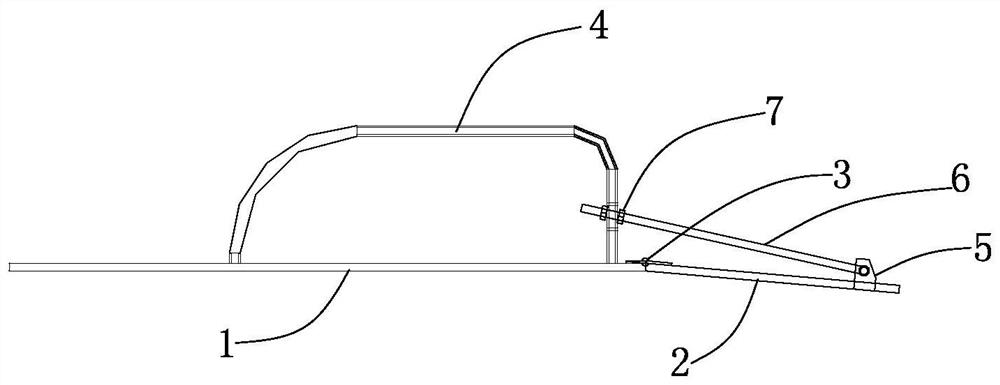

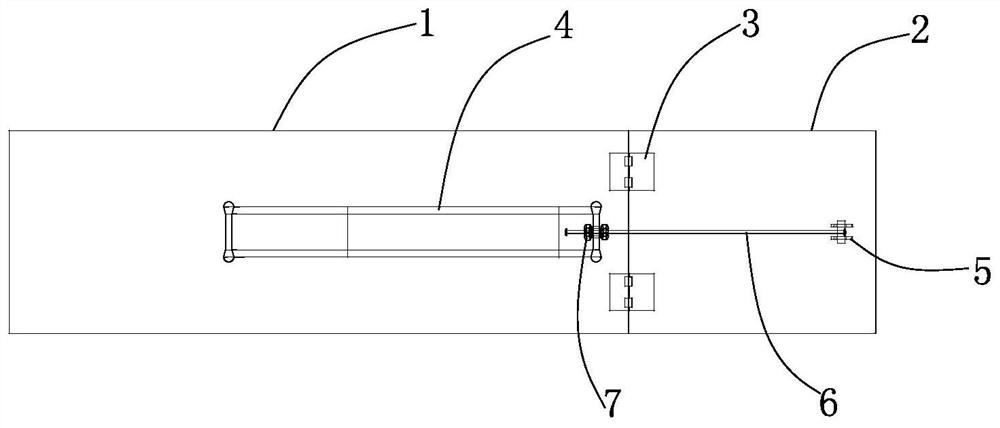

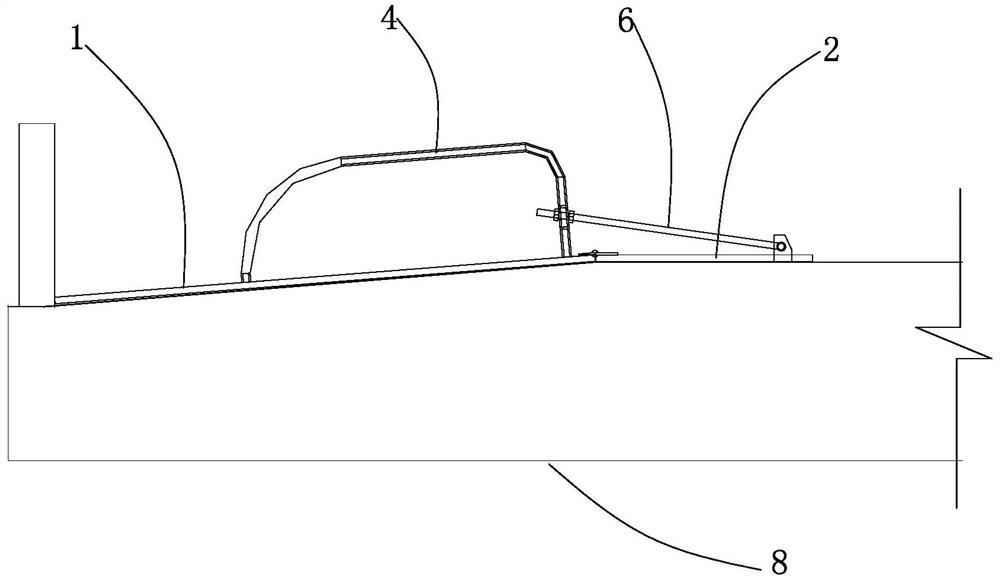

[0010] Such as figure 1 , figure 2 As shown, the present invention includes a rectangular slope closing scraper 1 and a rectangular slope control scraper 2, the length of the slope closing scraper 1 is equal to the width of the drainage slope of the ballastless track base plate, and the slope closing scraper 1 Align with one end of the slope control scraper 2, and set a loose leaf 3 at the joint of the slope control scraper and the slope control scraper, and the two sides of the loose leaf 3 are respectively connected with the top surface of the slope collection scraper 1 and the slope control scraper 2; The top surface of the slope control scraper 1 is provided with an inverted U-shaped handle 4 along the direction perpendicular to the alignment seam of the slope control scraper, and a through hole is arranged on the handle towards the side of the slope control scraper; the slope control scraper 2 Two lugs 5 are arranged on the top surface; a regulating rod 6 is movably connec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap