Chemical tanker deck unit header area pipeline installation precision control method

A technology for chemical tankers and control methods, which is applied to ships and other directions, can solve problems such as failure to meet accuracy requirements and heavy workload, and achieve the effects of reducing recalibration work, reducing production costs, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] In the description of the present invention, it is to be understood that the term "longitudinal", "horizontal", "upper", "lower", "front", "post", "left", "right", "vertical", The orientation of the "horizontal", "top", "bottom", "inside", "outside", etc., is based on the orientation or positional relationship shown in the drawings, is only for ease of describing the invention and simplified description, not Indicating or implying that the device or element must have a specific orientation, constructed and operated in a particular orientation, and thus is not to be construed as limiting the invention.

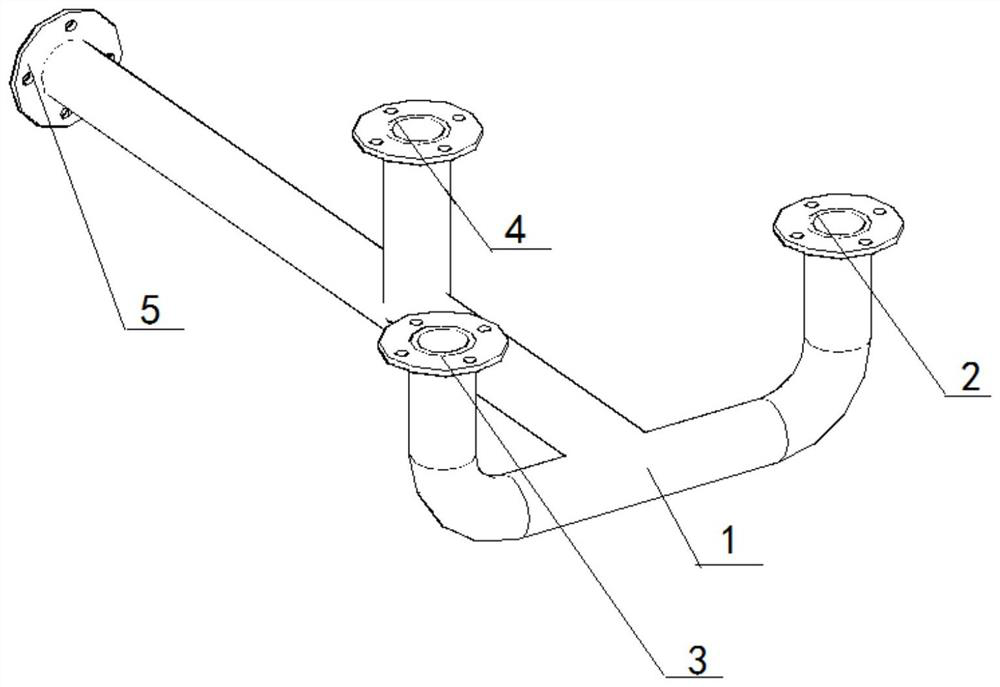

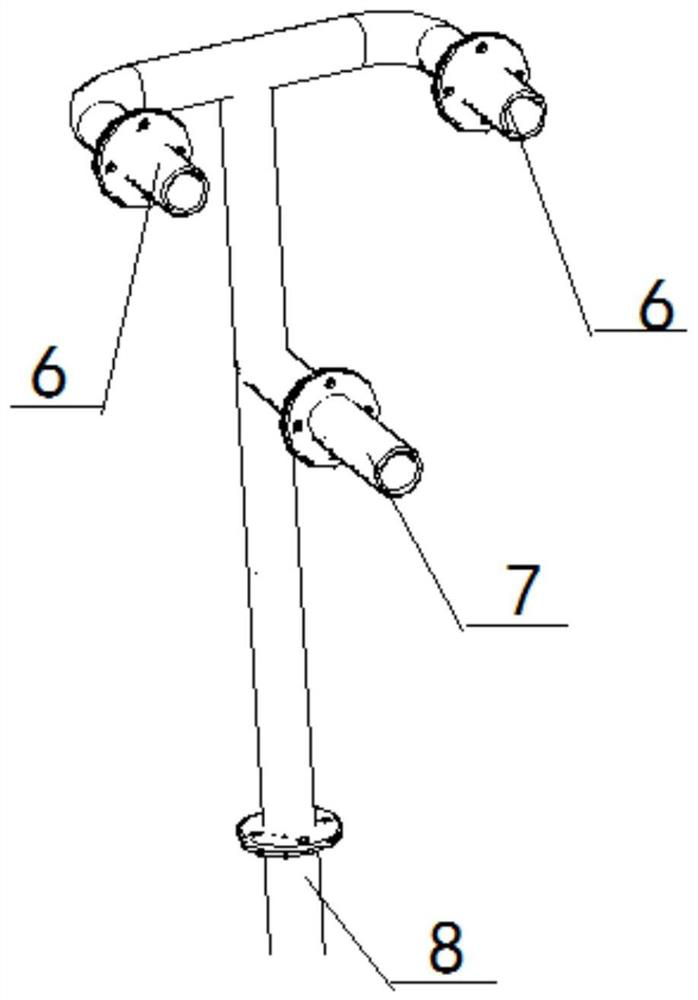

[0026] This embodiment provides a tube positioning detecting tool, including a pipeline frame 1, a pipe frame 1 is provided with four ports, and the four ports are connected to the first flange 2, the second flange 3, the third flange. 4 and fourth flange 5, the first flange 2, the second flange 3, the third flange 4 is defined on the same plane, defines the plane of the fourth

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap