Automatic refined sesame oil separating device

A small and automatic technology for grinding sesame oil, applied in the direction of separation method, sedimentation separation, edible oil/fat, etc., can solve the problem of high content of crude oil and sesame residue, achieve the effect of reducing the content of sesame residue and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

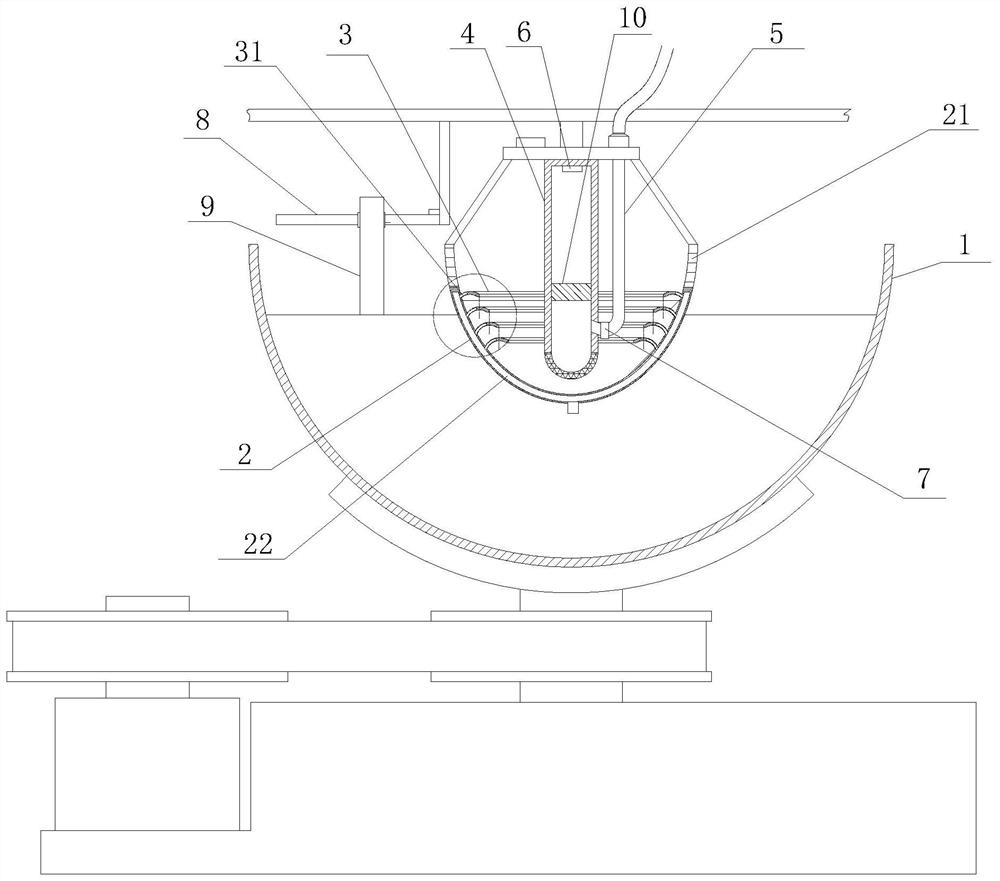

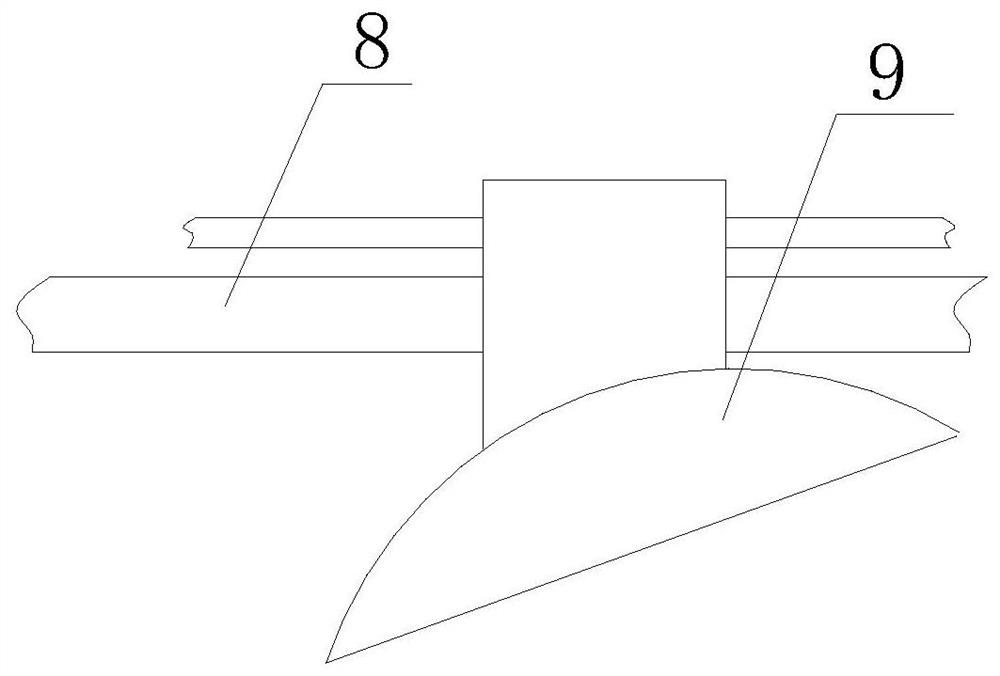

[0021] refer to figure 1 , a kind of small grinding sesame oil automatic oil separating device that the present invention proposes, comprises: wide-mouth container 1, be arranged on the flapper 2 of wide-mouth container 1 inner side and be used for driving the driving mechanism that flapper 2 vibrates up and down, to utilize When it vibrates at high frequency, the oil in the sesame oil separates and floats up.

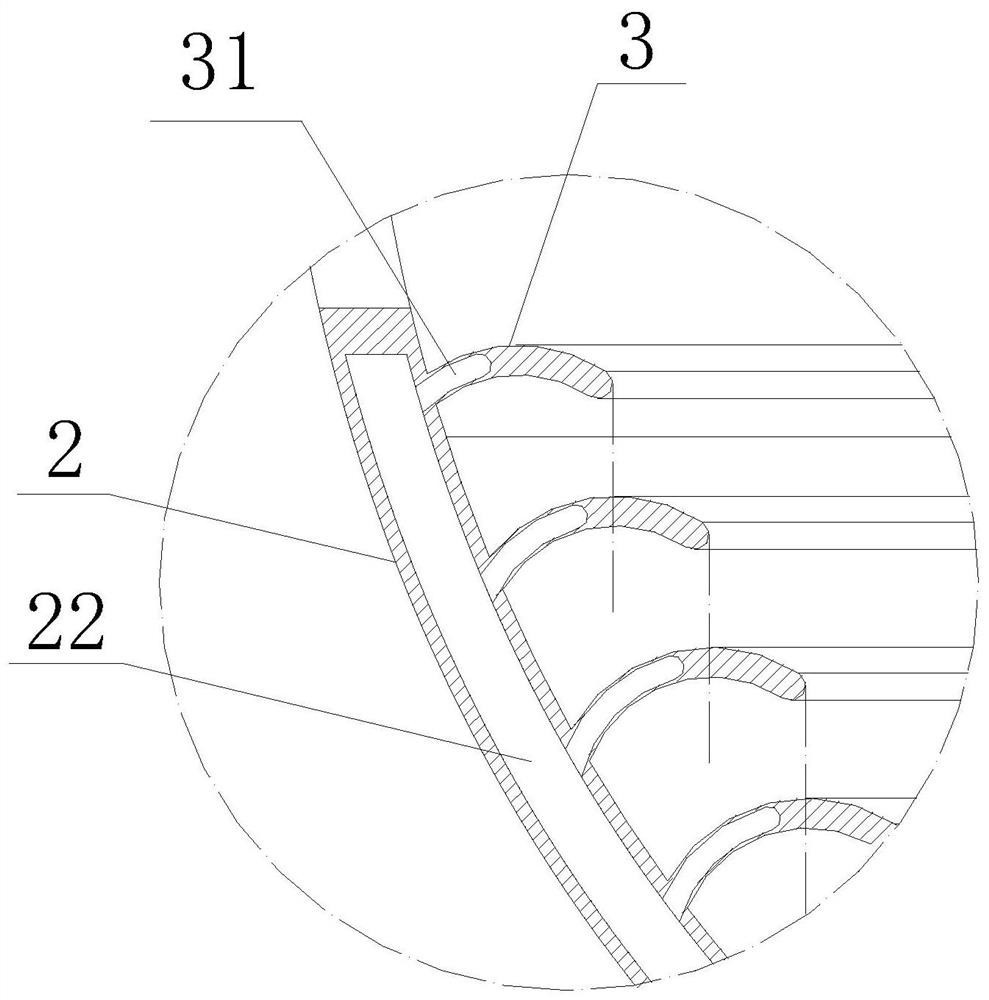

[0022] The centerline of the flapper 2 coincides with the centerline of the wide-mouthed container 1. The flapper 2 is a vessel with a circular arc bottom and an upward opening. The peripheral wall of the flapper 2 near its open end is provided with several peripheral The oil overflow port 21 arranged at intervals, so that the upper oil in the wide-mouth container 1 can enter the flapper 2 through the oil overflow port 21 . The inner side of the flapper 2 and below the oil spill port 2 are provided with a baffle 3 circumferentially arranged along its inner wall, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap