Tablet candy and preparation method thereof

A technology for tableting candy and fruit powder, which is applied in confectionery, confectionary industry, and oil-containing food ingredients, etc. It can solve the problems of reduced active ingredients of lipid substances, complicated preparation process, and easy sticking of punches, etc., to achieve taste and nutrition Healthy, simple preparation process, not easy to stick punch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

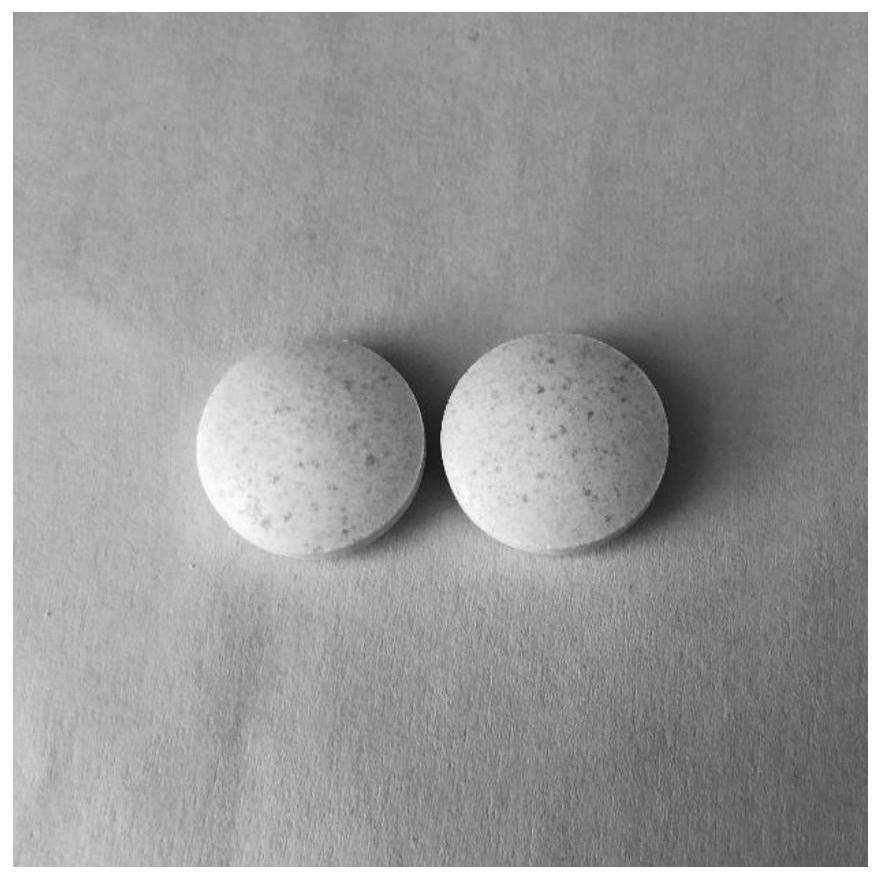

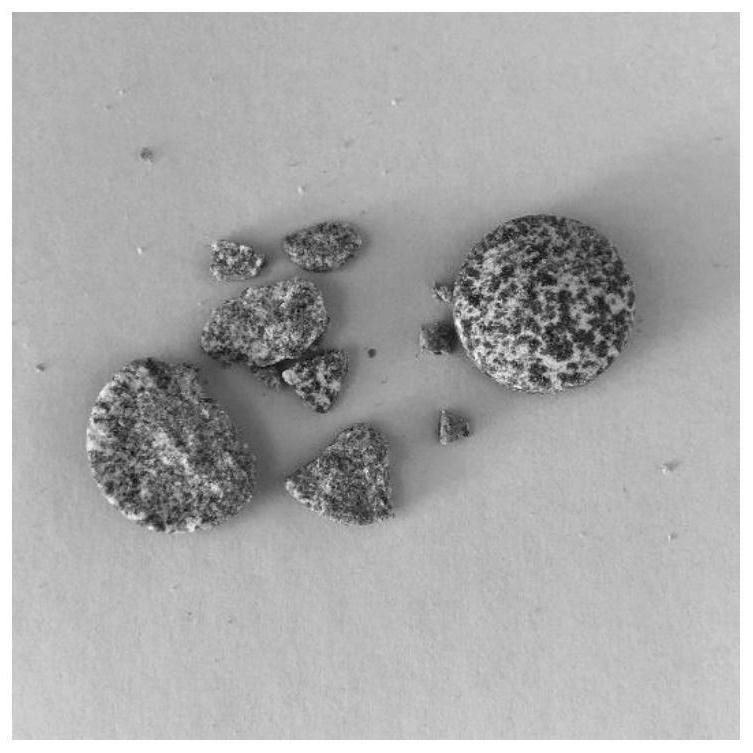

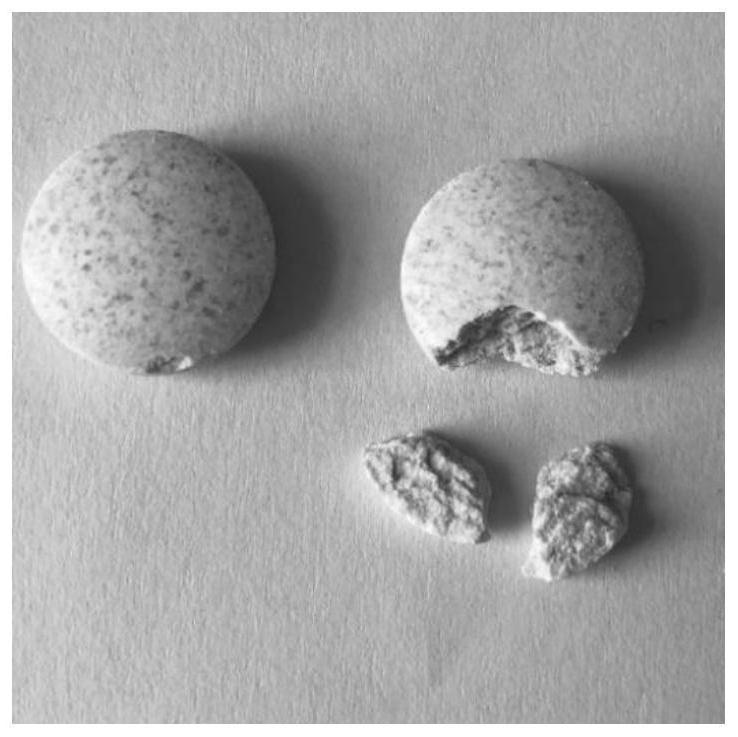

Image

Examples

Embodiment 1

[0078] Raw material composition and content:

[0079] Element Dosage / g Lutein Esters 9.4 resistant dextrin 40 Maltitol 40 Sorbitol 10 silica 0.6

[0080] The preparation steps are as follows:

[0081] Step (1) mixing each component in the above components except the lubricant in a dry blender for 5 minutes to obtain a mixture;

[0082] Step (2) add a lubricant to the mixture, and then mix for 6 minutes to obtain a total mixture; put the total mixture into a tablet machine for tablet compression, the speed of the tablet machine turntable is 10 rpm, the filling depth of the material is 4.5 mm, and the pre-compression thickness is 4.5 mm. 2.0mm, tablet thickness 1mm, tablet diameter 5mm, pressure 10KN.

[0083] The tableted candy of this embodiment does not stick to the punch, is not easy to split during the tableting process, has good tabletability, the tablet is not easy to absorb moisture, does not oxidize within 90 days, does not

Embodiment 2

[0085] Raw material composition and content:

[0086]

[0087]

[0088] The preparation steps are as follows:

[0089] Step (1) mixing each component except the lubricant in the above components for 6 minutes in a dry blender to obtain a mixture;

[0090] Step (2) add lubricant to the mixture, continue mixing in the dry blender for 7 minutes to obtain a total mixture; put the total mixture into a tablet press for tableting, the speed of the tabletting machine turntable is 12rpm, and the filling depth of the material is 5mm, The pre-compression thickness is 3mm, the tablet thickness is 1.2mm, the tablet diameter is 7mm, and the pressure is 12KN.

[0091] The tableted candy of this embodiment does not stick to the punch, is not easy to split during the tableting process, has good tabletability, the tablet is not easy to absorb moisture, does not oxidize within 90 days, does not flake, and does not stick to the teeth. The content of phosphatidylserine in the sliced candy r

Embodiment 3

[0093] Raw material composition and content:

[0094] Element Dosage / g algal oil DHA 8 resistant dextrin 19.7 Maltitol 35 Sorbitol 35 Sweet Orange Fruit Powder 1 citric acid 0.2 malic acid 0.3 Magnesium stearate 0.8

[0095] The preparation steps are as follows:

[0096] Step (1) mixing each component except the lubricant in the above components for 6 minutes in a dry blender to obtain a mixture;

[0097] Step (2) Add lubricant to the mixture, and continue mixing in the dry mixer for 7 minutes. The blend was obtained; the blend was put into a tablet press for tablet compression, the turntable speed of the tablet press was 15 rpm, the filling depth of the material was 6 mm, the pre-compression thickness was 3.5 mm, the tablet thickness was 1.4 mm, the tablet diameter was 9 mm, and the pressure was 14KN.

[0098] The tableted candy of this embodiment does not stick to the punch, is not easy to split during the tabl

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap