Digital underwater welding power source capable of outputting multiple external characteristics and working method thereof

A technology of underwater welding and external characteristics, applied in the output power conversion device, welding accessories, irreversible AC power input into DC power output and other directions, can solve the problem of single output external characteristics, etc., to achieve high software programming flexibility , the effect of increasing the versatility and simplifying the structure of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] Example

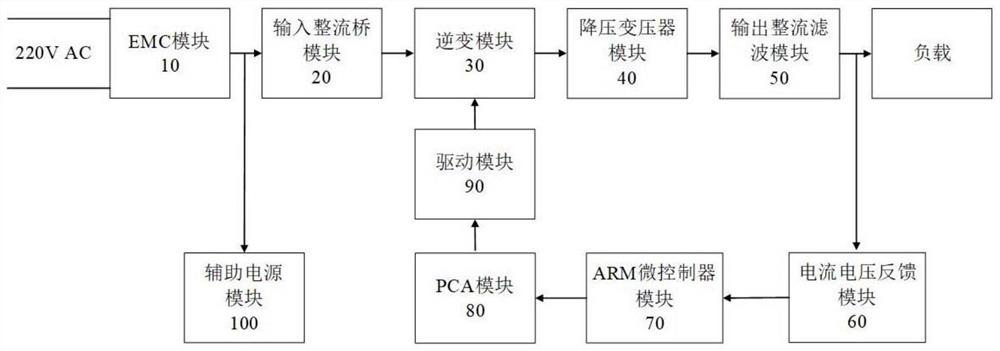

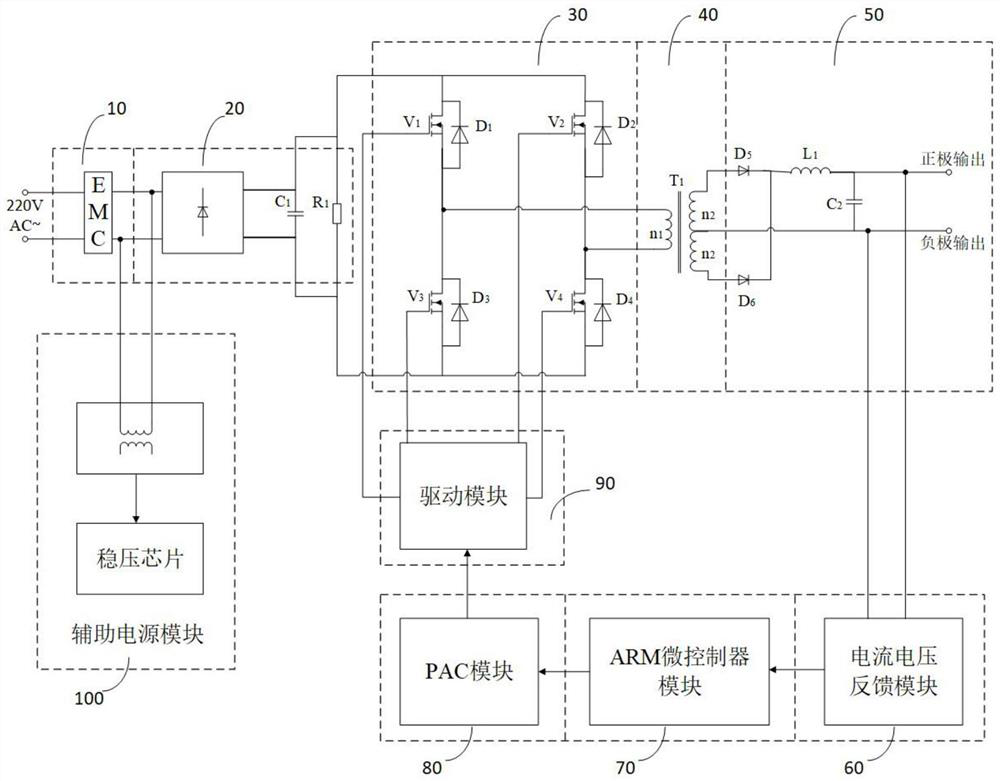

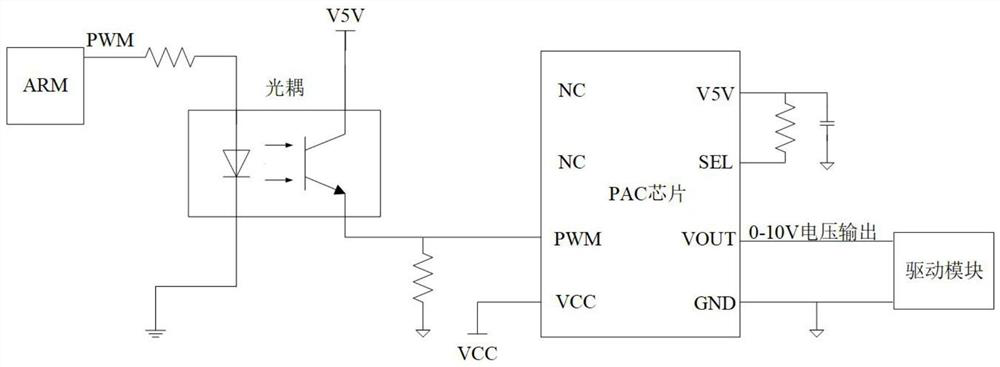

[0056] This example discloses digital underwater welding power supplies that can output multi-external characteristics, and the external characteristic output includes constant current exterior characteristics, constant voltage external characteristic output, and constant power external characteristic output. Such as figure 1 As shown, the welding power source includes an EMC module 10, an input rectifier bridge module 20, an inverter module 30, a step-down transformer module 40, an output rectifier filter module 50, a current voltage feedback module 60, an ARM microcontroller module 70, a PAC module 80 The drive module 90, the auxiliary power module 100.

[0057] The EMC module, the input rectifier bridge module, the inverter module, the buck transformer module, and the output stream filter module are sequentially connected and the output rectification filter module is connected to the load as a forward path of the solder power source main circuit.

[0058] The AC e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap