Single crystal furnace capable of automatically dismounting single crystal rods and dismounting method thereof

An automatic disassembly, single crystal rod technology, applied in the direction of single crystal growth, chemical instruments and methods, self-melting liquid pulling method, etc., can solve the problem of easy burns for operators, and achieve the effect of avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

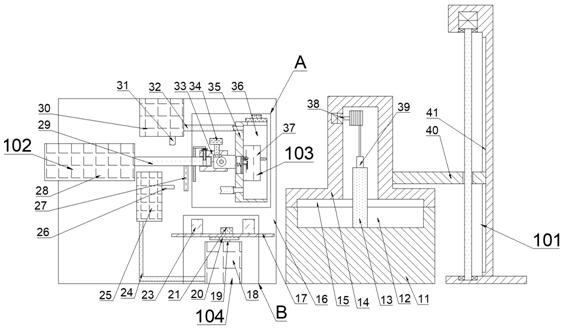

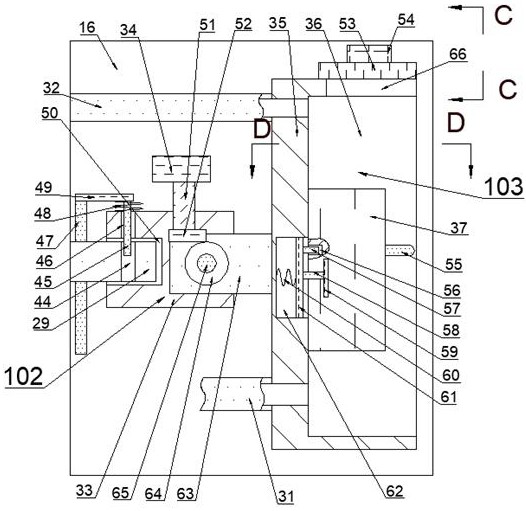

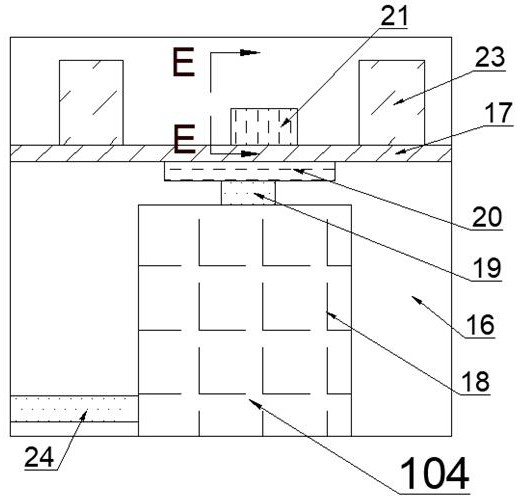

[0025] Combine below Figure 1 to Figure 6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026] A single crystal furnace with automatic disassembly of single crystal rods according to the present invention includes a single crystal furnace base 11, on which a single crystal furnace main body 101 is arranged, and the single crystal furnace main body 101 is used for producing single crystal rod, the left side of the base 11 of the single crystal furnace is provided with a frame 16, and the front end surface of the frame 16 is provided with a single crystal rod disassembly mechanism 102, and the single crystal rod disassembly mechanism 102 is used to provide a disassembly unit Transversal movement required for crystal ingots and rotational movement required for stora...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap