Five-axis any-angle cutting device

A cutting device and any angle technology, which is applied in the direction of sawing machine, metal sawing equipment, maintenance and safety accessories, etc., can solve the problems that the saw blade cannot rotate freely, the limitation of cutting equipment is large, and the cutting quality of the workpiece is poor, so as to reduce the Small limitations, the effect of improving cutting quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1:

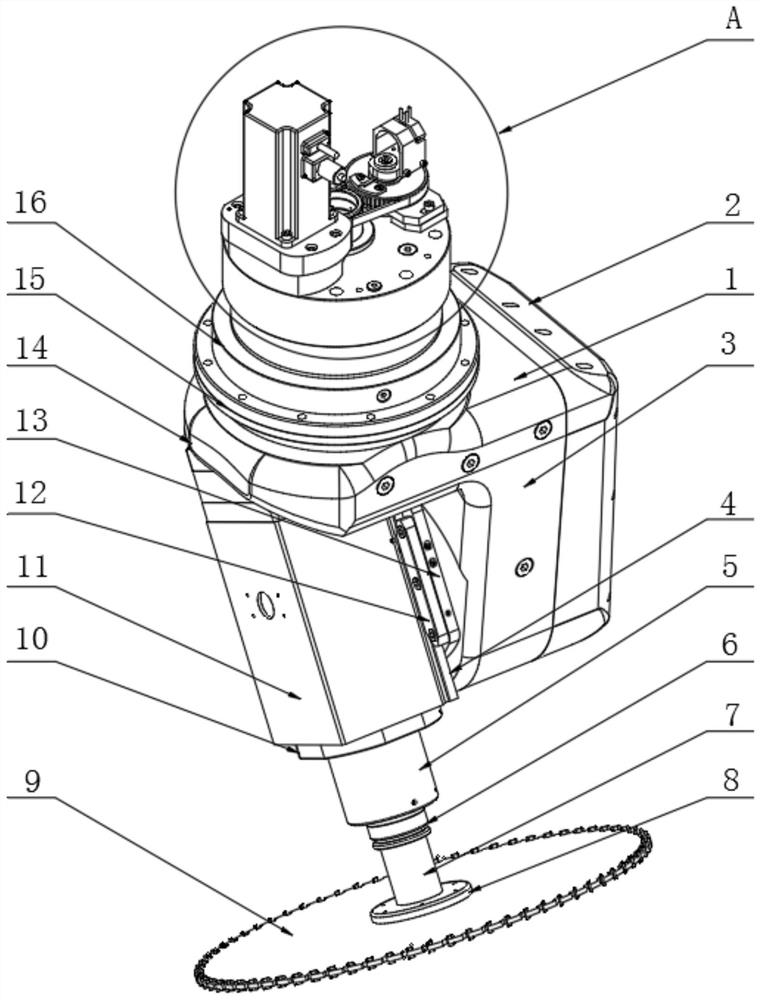

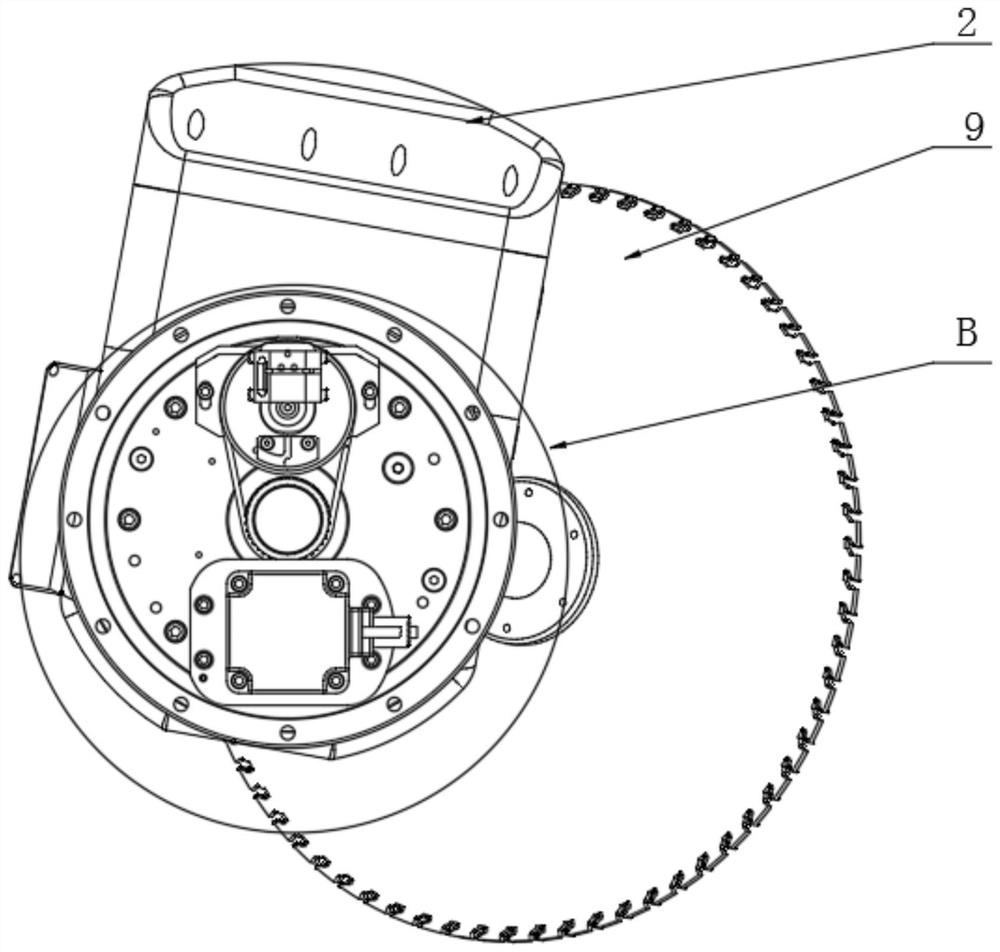

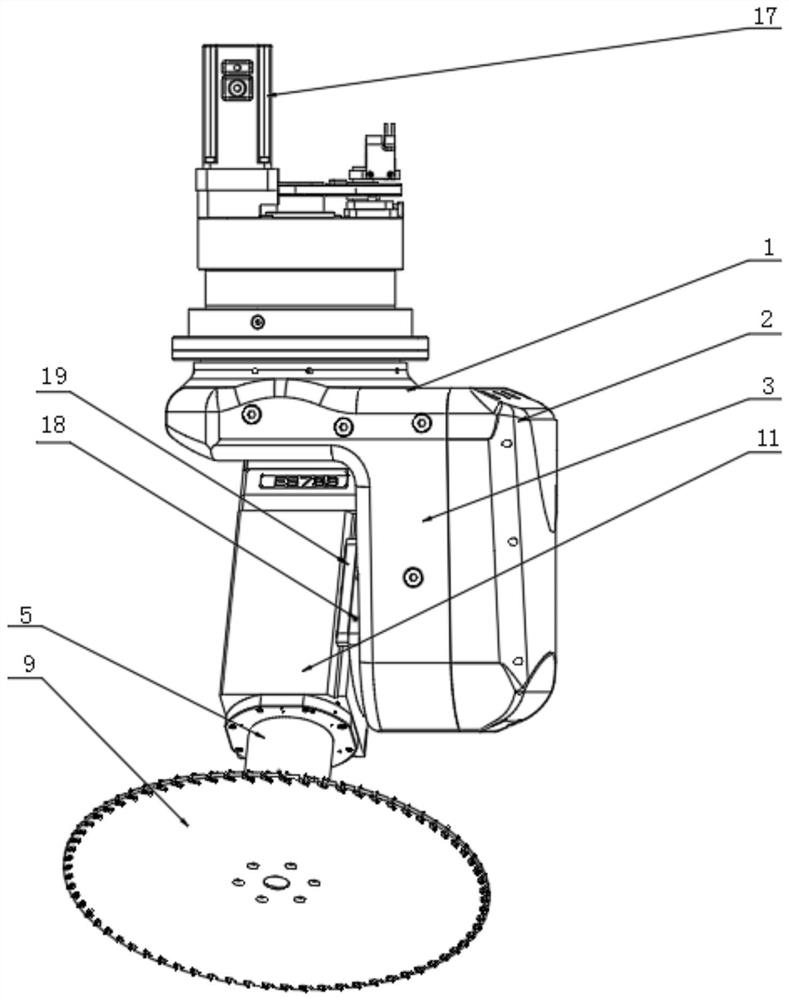

[0028] Refer to the attachment Figure 1-6 , A five-axis arbitrary angular cutting device provided by the present invention includes a top case 1, and the upper top casing 1 is provided with a protective cover 3, and the upper housing 1 and the protective cover 3 are fixed by bolts, the upper A five-axis fixture is provided at the top of the top shell 1, and a saw blade mechanism is provided at the bottom of the protective cover 3;

[0029] The five-axis fixing mechanism includes a shaft disk 15, which is fixed to the top of the upper housing 1, and the top of the shaft disk 15 is provided with a casing 16, and the shaft disk 15 and the casing 16 are fixed by bolts. The upper portion of the casing 16 is provided with a support cover 20, and the casing 16 is fixed by a bolt, and the top portion of the support cover 20 is provided with a mounting flange 25, the support cover 20 and the mounting flange 25 through the bearing. Connecting, the mounting flange 25 is fixe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap