Anti-fingerprint fluoride-free coating and preparation method thereof

A fluorine coating and anti-fingerprint technology, applied in the field of anti-fingerprint fluorine-free coating and its preparation, can solve the problems of anti-fingerprint coating relying on special equipment, increasing production cost and time, unfavorable for industrialized production, etc. The effect of using the scene range, reducing the emission of toxic gas, and good anti-fingerprint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

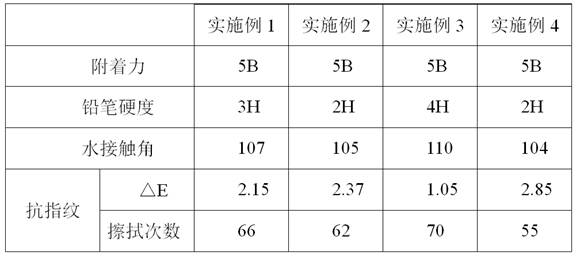

Examples

Embodiment 1

[0056] A preparation method of an anti-fingerprint fluorine-free coating, comprising the following steps:

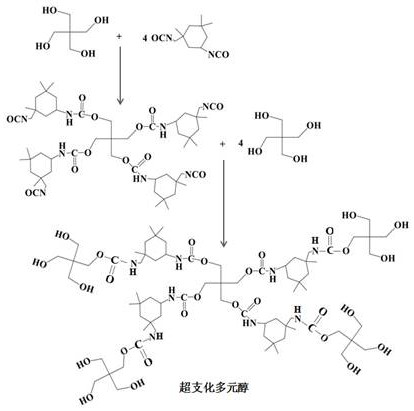

[0057] (1) Preparation of hyperbranched polyols:

[0058] Add 88.8 parts of isophorone diisocyanate to the reaction vessel, vacuumize at 110°C for 30 minutes, add 1.19 parts of dibutyltin dilaurate, add 29.8 parts of pentaerythritol dropwise, keep the reaction at 70°C for 1.5h, then add 119.2 parts dropwise Capped with pentaerythritol, kept at 70°C for 3 hours, and dried to obtain hyperbranched polyols;

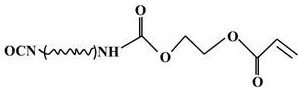

[0059] (2) Preparation of semi-addition acrylate modified silicone resin:

[0060] Add 105.5 parts of isophorone diisocyanate into the reaction vessel, vacuumize at 110°C for 30 minutes, add 200 parts of hydroxy polysiloxane, 4.0 parts of dibutyltin dilaurate catalyst and keep it at 90°C for 1 hour, then put 6.0 parts of Add 1,4-butanediol dropwise into the reaction vessel, keep the temperature at 90°C for 2 hours, then cool down to 75°C, add 2.0 parts of p-hydroxyanisol

Embodiment 2

[0066] A preparation method of an anti-fingerprint fluorine-free coating, comprising the following steps:

[0067] (1) Preparation of hyperbranched polyols:

[0068] Add 88.8 parts of isophorone diisocyanate to the reaction vessel, vacuumize at 110°C for 35 minutes, add 1.9 parts of stannous octoate, dropwise add 29.8 parts of pentaerythritol, keep the reaction at 75°C for 1 hour, then add dropwise 119.2 parts of pentaerythritol to seal end, heat preservation reaction at 70°C for 3h, and dry to obtain hyperbranched polyol;

[0069] (2) Preparation of semi-addition acrylate modified silicone resin:

[0070] Add 195.4 parts of isophorone diisocyanate into the reaction vessel, vacuumize at 110°C for 35 minutes, add 300 parts of hydroxy polysiloxane, 2.9 parts of stannous octoate catalyst, keep the reaction at 85°C for 1.5 hours, and then put 11.8 Parts of 1,6-hexanediol were added dropwise to the reaction vessel, and after heat preservation at 90°C for 2 hours, the temperature was

Embodiment 3

[0075] (1) Preparation of hyperbranched polyols:

[0076] Add 50.4 parts of 1,6-hexamethylene diisocyanate into the reaction vessel, vacuumize at 110°C for 30 minutes, add 1.0 parts of bismuth neodecanoate, add dropwise 13.4 parts of trimethylolpropane, and keep the reaction at 70°C After 2 hours, add 40.2 parts of trimethylolpropane dropwise, keep the temperature at 70°C for 3 hours, and dry to obtain hyperbranched polyols;

[0077] (2) Preparation of semi-addition acrylate modified silicone resin:

[0078] Add 142.8 parts of 1,6-hexamethylene diisocyanate into the reaction vessel, vacuumize at 110°C for 30 minutes, add 150.0 parts of hydroxy polysiloxane, 3.5 parts of bismuth neodecanoate catalyst, and keep the reaction at 90°C for 1 hour , and then add 21.2 parts of diethylene glycol dropwise into the reaction vessel, keep the temperature at 85°C for 2 hours, then cool down to 75°C, add 2.6 parts of 2,5-di-tert-butylhydroquinone, dropwise 119.2 parts of pentaerythritol triac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap