Double-layer sealing structure

A double-layer sealing, graphite sealing technology, applied in shaft sealing, engine sealing, valve details, etc., can solve the problems of increased working steam consumption, low suction pressure, large air leakage, etc., and achieve wide application prospects , The effect of improving air leakage and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

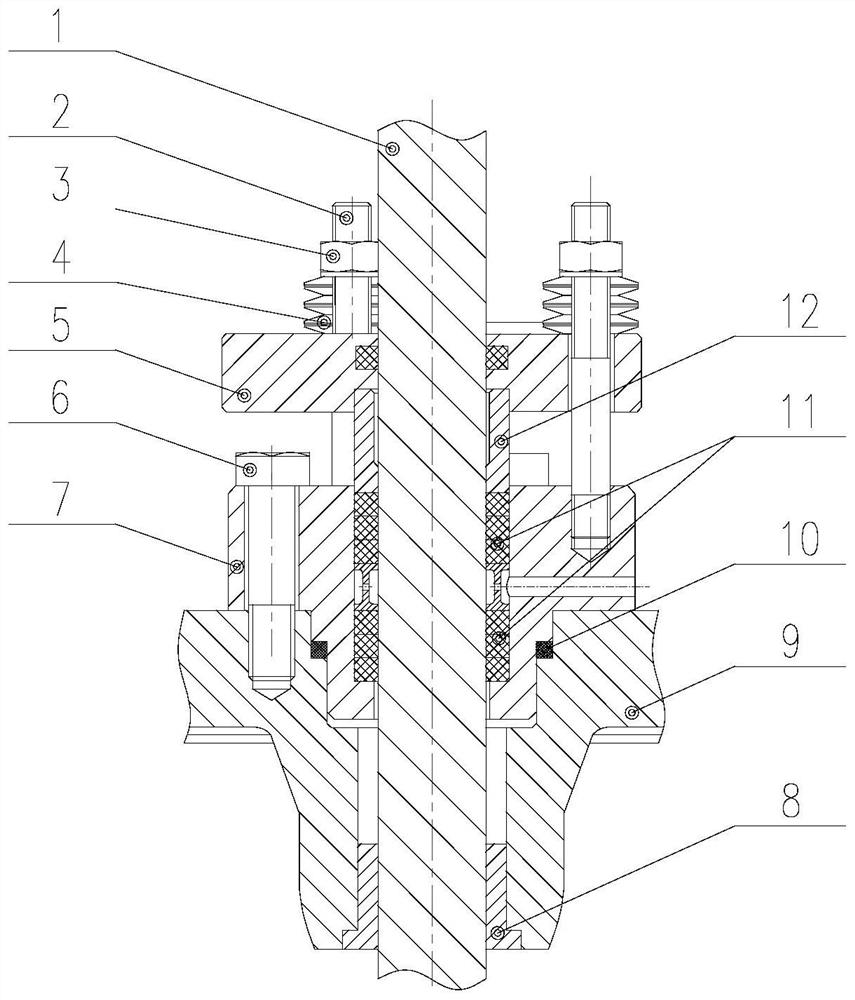

[0025] The present invention will be further described below with reference to the accompanying drawings.

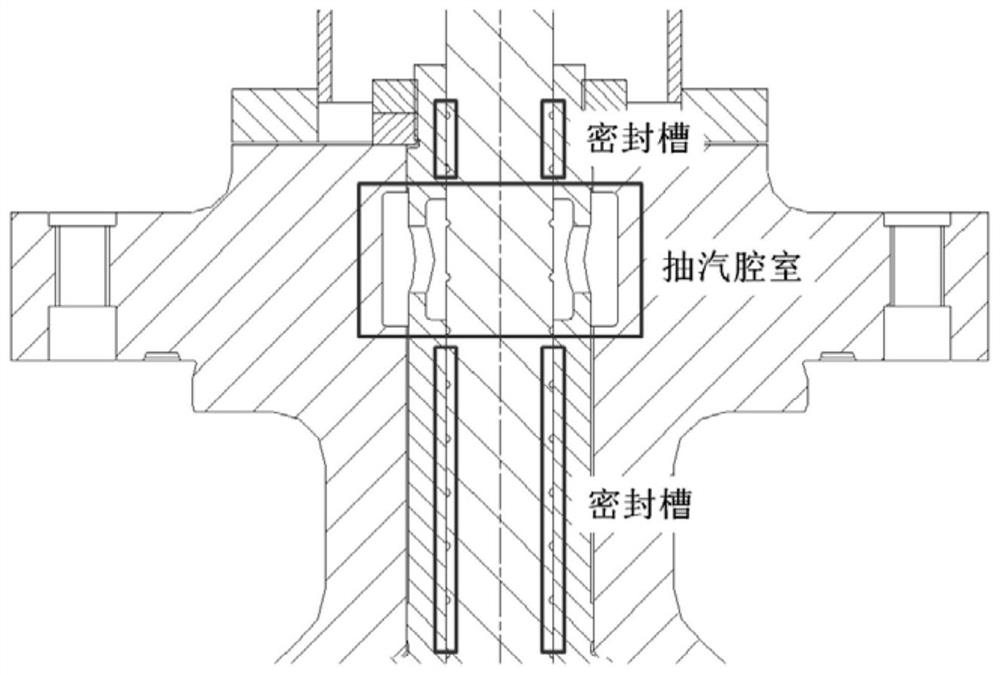

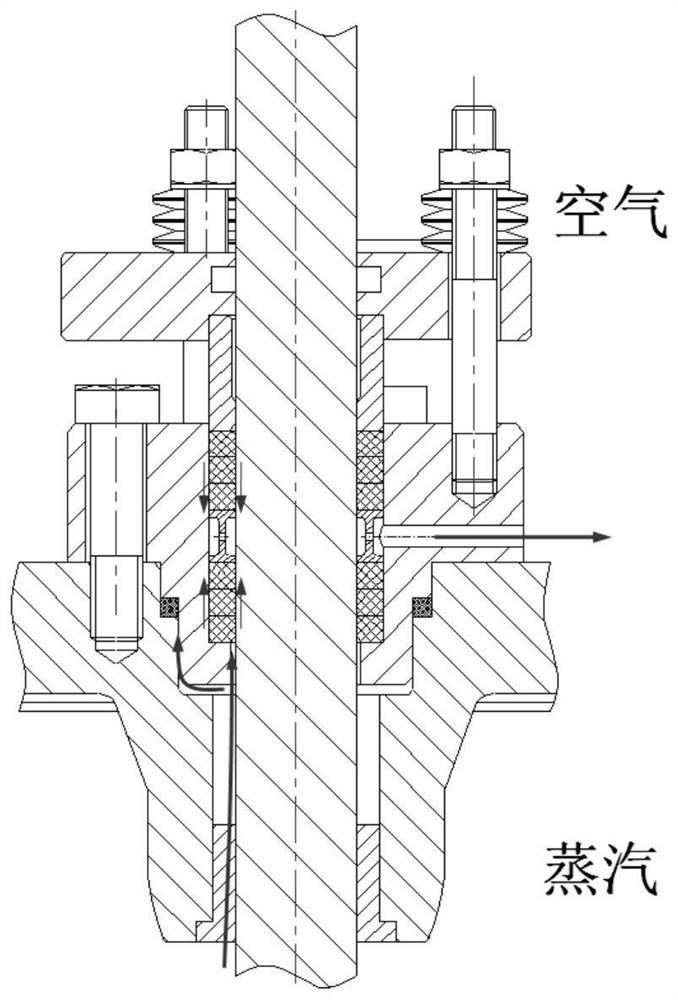

[0026] like figure 2 As shown, the sealing effect of the double layer sealing structure of the present invention is mainly based on the sealing ring and the graphite sealing filler.

[0027] The structure includes a valve stem 1, the stud 2, the nut 3, the disc spring 4, the upper compression cover 5, the bolt 6, the lower compression cover 7, the lower bushing 8, the valve body 9, sealing ring 10, graphite sealing filler 11, Bushne 12. The lower end bushing 8 is contained in the lower end of the valve body 9, and the upper end is fixed to the lower compression cover 7 by the bolt 6, and the upper surface of the lower compression cover 7 is connected by the stud 2, the nut 3 and the disc spring 4, the valve stem 1 and the valve body The lower bushing 8 in the 9 is mounted, and the multilayer graphite sealing filler 11 is provided between the valve stem 1 and the lower pressure

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap