Preparation method of monodisperse mesoporous silica hollow sphere material

A technology of mesoporous silica and silicon dioxide, which is applied in the direction of silicon dioxide and silicon oxide, can solve the problem of high cost of sacrificial templates and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

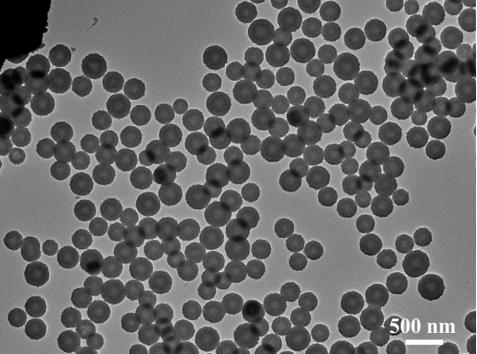

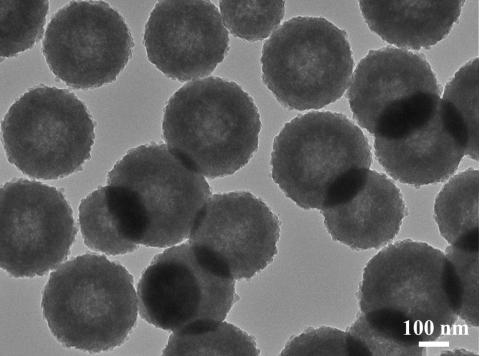

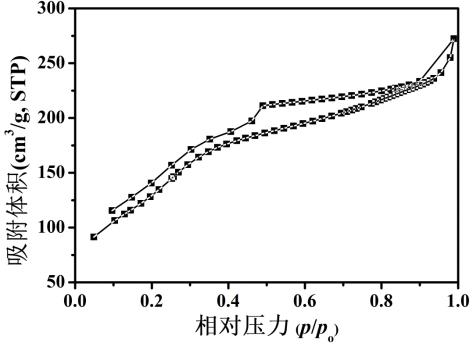

Image

Examples

Embodiment 1

[0033] A preparation method of a monodisperse mesoporous silica hollow sphere material, comprising:

[0034] (1) Dissolve 2.0 g of ethylenediamine in a mixed solution of 50 mL of deionized water and 100 mL of ethanol, and stir evenly to form a colorless and transparent solution. The stirring speed of the above stirring can be selected from 250-1200 rpm, and the time can be controlled at 0.1-10 h; the stirring speed selected in this embodiment is 300 rpm, and the time is 0.5 h. The stirrer used therein may be a turbine stirrer, a paddle stirrer, a magnetic stirrer, a magnetic heating stirrer, a flap stirrer, or a mechanical stirrer.

[0035] 8 mL of ethyl orthosilicate was slowly added to the clear solution to form a single-phase system.

[0036] (2) The single-phase system in step (1) was reacted in an oil bath at a temperature of 15 °C for 24 h; after the reaction, the precipitate was collected by centrifugation and washed three times with water to obtain a monodisperse mesopor

Embodiment 2

[0040] A preparation method of a monodisperse mesoporous silica hollow sphere material, comprising:

[0041] (1) Dissolve 6 g of ethylenediamine in a mixed solution of 10 mL of deionized water and 140 mL of ethanol, and stir evenly to form a colorless and transparent solution. The stirring speed of the above stirring can be selected from 250-1200 rpm, and the time can be controlled at 0.1-10 h; the stirring speed selected in this embodiment is 1000 rpm, and the time is 10 h. The stirrer used therein may be a turbine stirrer, a paddle stirrer, a magnetic stirrer, a magnetic heating stirrer, a leaf type stirrer, or a mechanical stirrer;

[0042] 3 mL of propyl orthosilicate was slowly added to the clear solution to form a single-phase system.

[0043] (2) The single-phase system in step (1) was reacted in an oil bath at a temperature of 40 °C for 24 h; after the reaction, the precipitate was collected by centrifugation and washed with water three times to obtain a monodisperse mes

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap