Method of recombining bamboo material into reinforced shapes

A molding material and solidification molding technology, which is applied in wood processing appliances, wooden veneer joints, household components, etc., can solve the problems of high cost, lack of natural texture of bamboo, high glue consumption, etc., and achieve the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

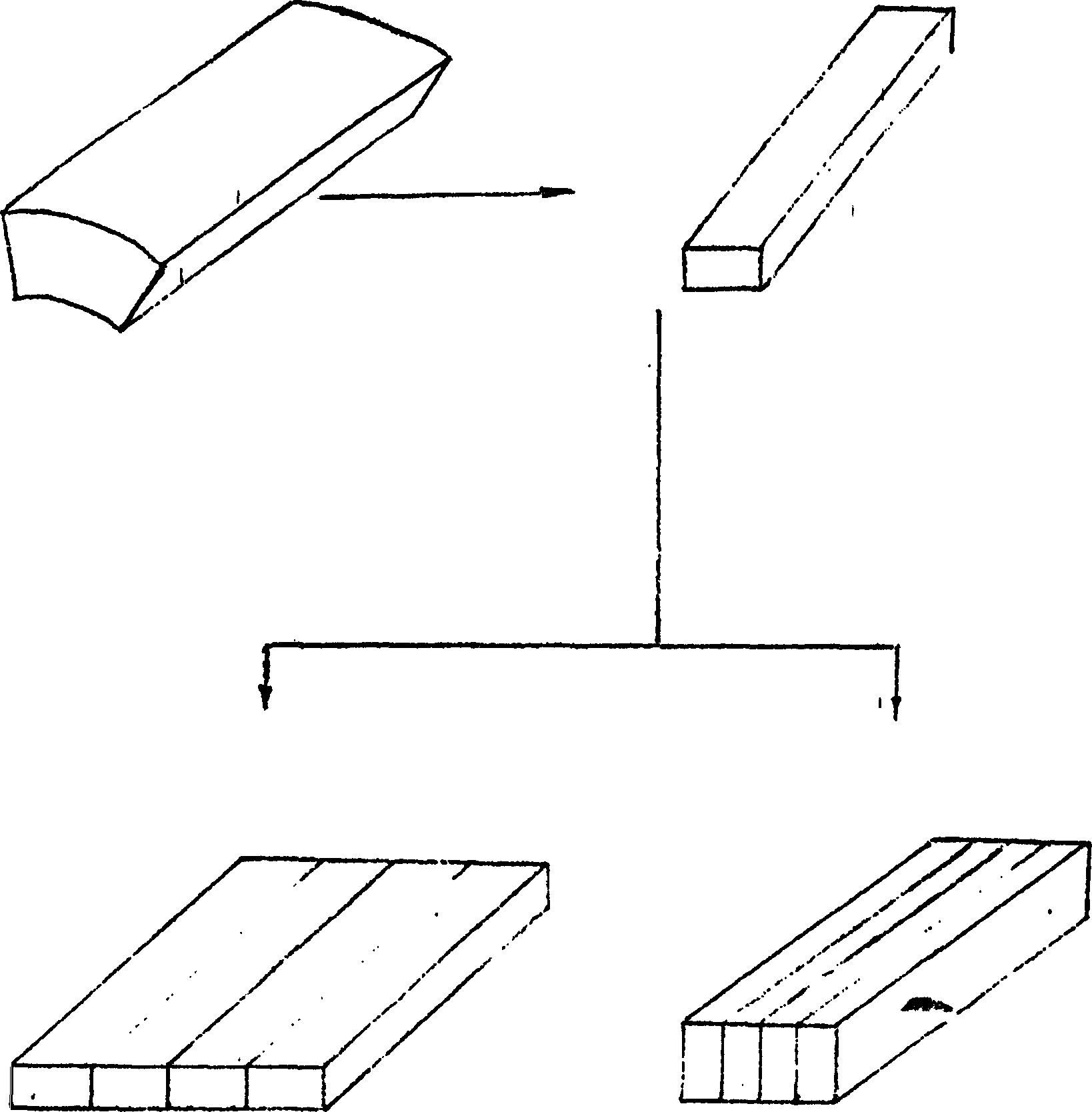

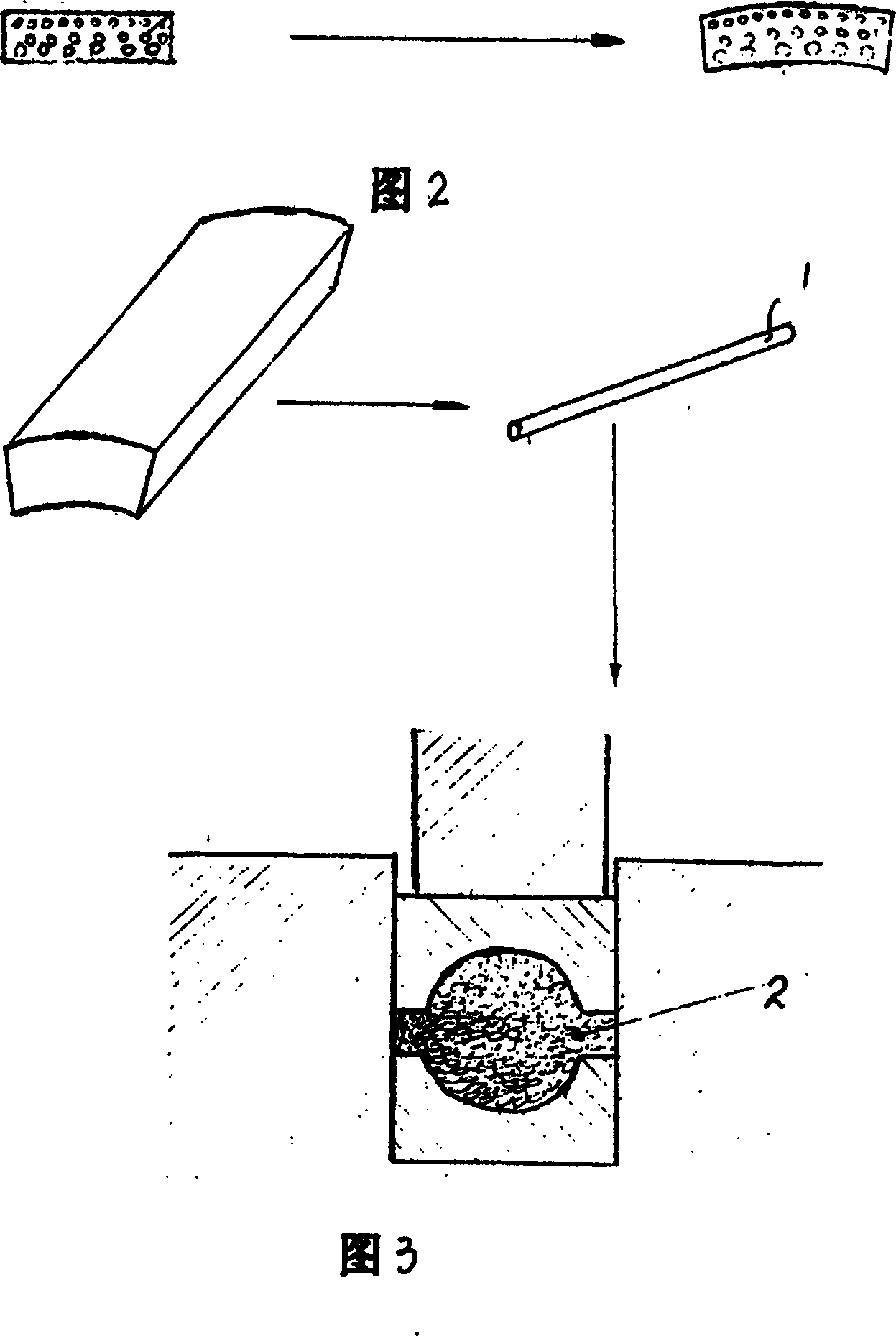

[0023] Refer to accompanying drawing 3. The method for reorganizing and strengthening the shaped material of bamboo of the present invention is to cut off the moso bamboo. Split into bamboo filaments, dip in glue after drying, install molds, press and solidify the shaped materials.

[0024] Specifically, wet moso bamboo is used, cut into required lengths, split into bamboo slices 1, drawn 2 with a wire drawing machine, and then dried.

[0025] Take the dried bamboo silk for dipping. Glue can choose phenolic adhesive, melamine-formaldehyde adhesive, epoxy adhesive, unsaturated resin adhesive, polyurethane adhesive and other adhesives with good water resistance, try to avoid using urine aldehyde with poor water resistance of adhesives.

[0026] Bamboo silk is soaked in glue, dried in solvent, then filled in a mold, pressed with a press at a pressure of 10-100Mpa, and heated to fully cure.

[0027] After curing, the mold is demoulded, and a piece of bamboo is restructured and st

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap