Cleaning device for drafting mechanism of drawing frame

A cleaning device and drawing frame technology, applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve the problems of increased workload of workers, cumbersome operation process, shortened service life of cleaning curtains, etc., to ensure electrostatic adsorption Efficiency, good cleaning effect, convenient replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

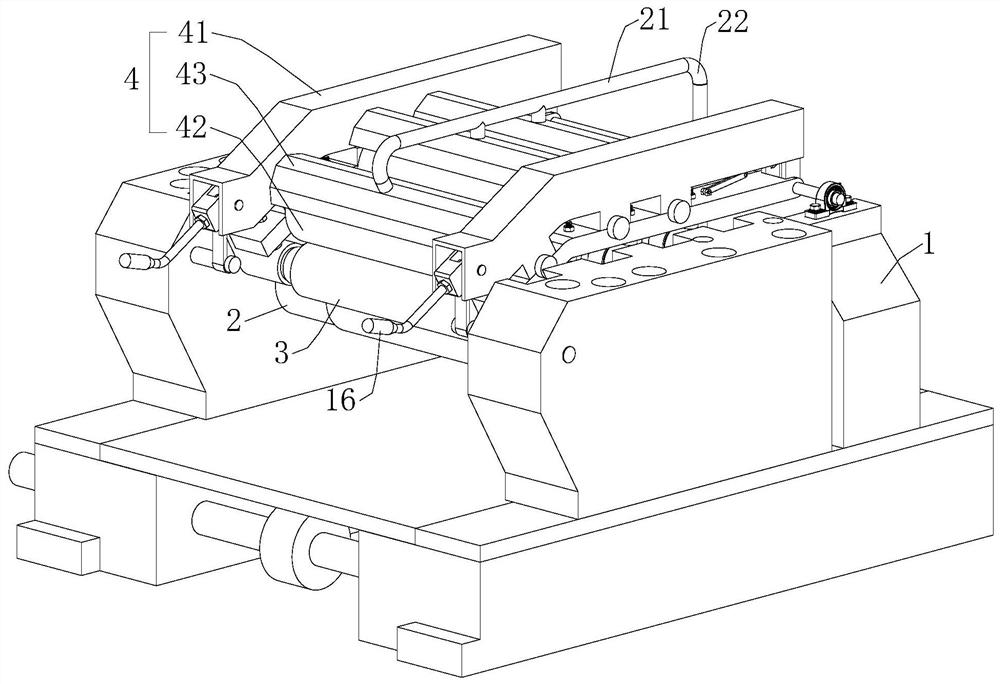

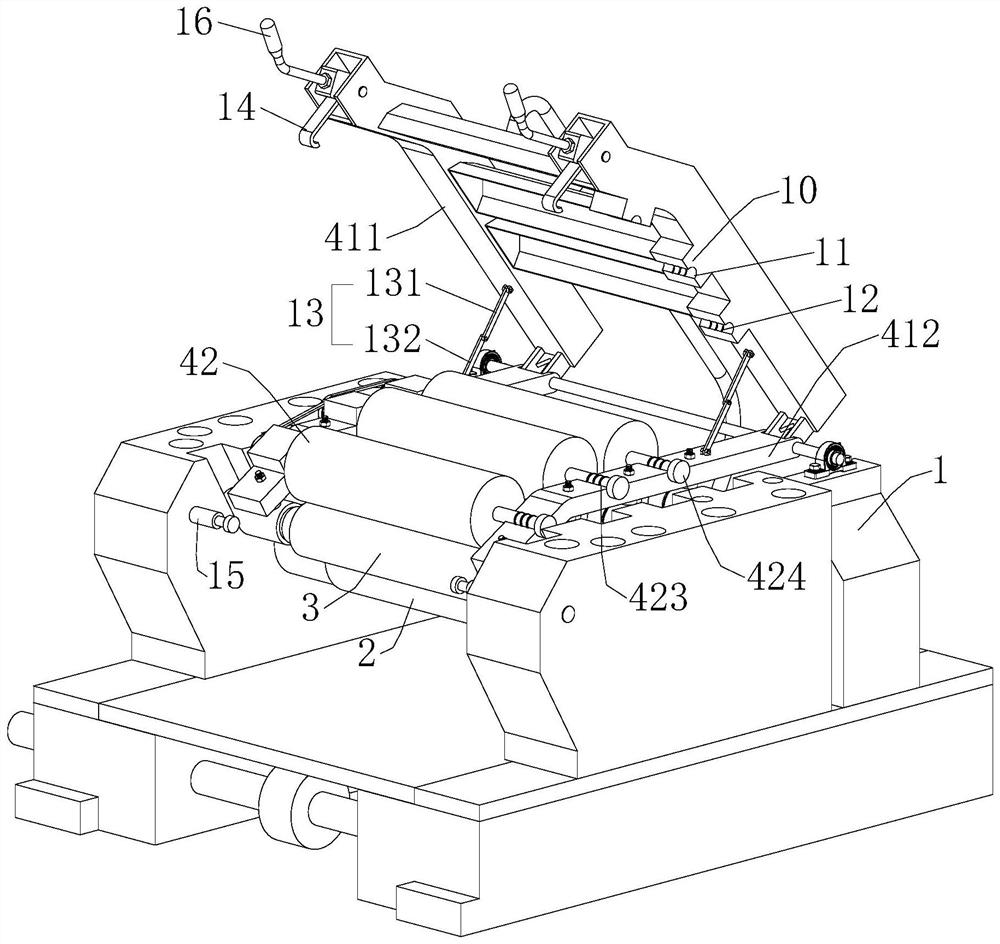

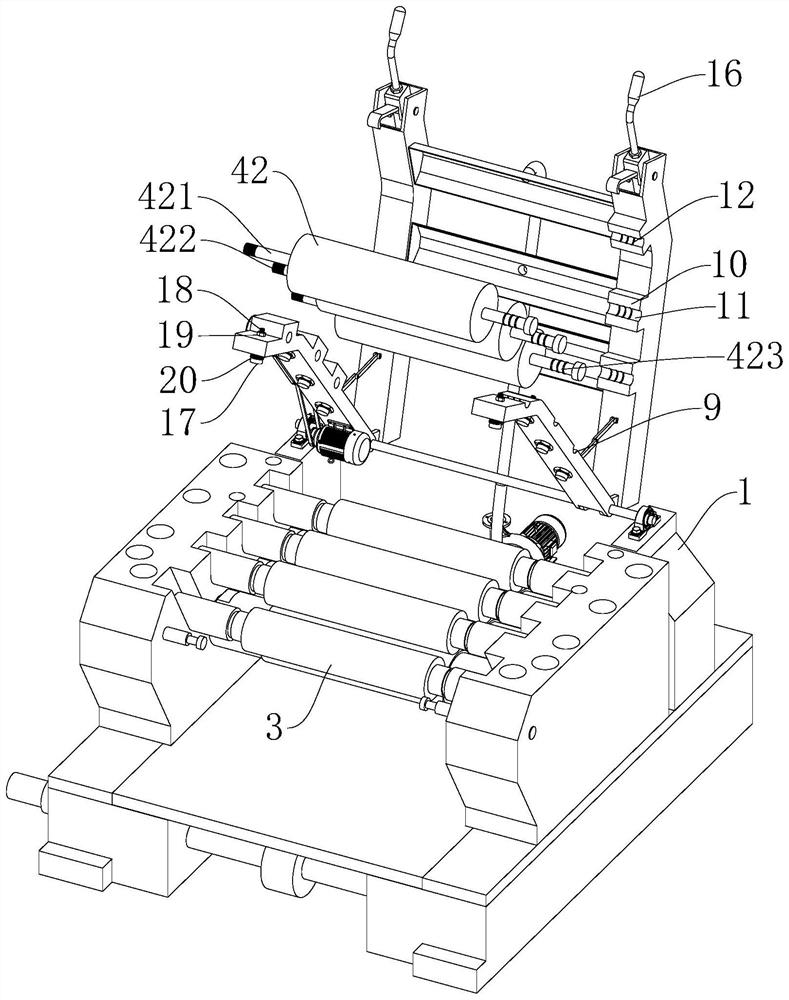

[0037]Example: Cleaning device for the drafting mechanism of a draw frame, such as figure 1 , figure 2 As shown, it includes frame 1, on which frame 1 is rotatably connected with a group of drafting rollers 2, and drafting rollers 2 are three upper and three lower pressure bars with guide rollers 3, four guide rollers 3 are provided, and guide rollers The roller 3 is rotatably connected to the frame 1. The frame 1 is also provided with a cleaning mechanism 4. The cleaning mechanism 4 includes two support frames 41 hinged on the frame 1. The two support frames 41 are respectively located at the two ends of the guide top roller 3. The support frame 41 is divided into upper frame 411 and The lower frame 412, three cleaning rollers 42 are detachably connected between the two lower frames 412, the lower end surface of the cleaning roller 42 is located between two adjacent guide rollers 3, and is connected to the adjacent two guide rollers 3, A number of dust suction covers 43 are f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap