Method for synthesizing sugar-undisturbed alpha-glucan with different tightness degrees in vitro

A technology for in vitro synthesis and dextran, which is applied in fermentation and other directions, and can solve problems such as fine structure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In high concentration phosphate buffer (160mM KH 2 PO 4 and 240mM Na 2 HPO 4 , pH=7.0) add 240mM sucrose and 0.4mM maltotriose (the molar ratio of sucrose to maltotriose is 600:1), and after incubating at 55℃ for 20min, firstly add 5, 15, 22.5, 30 and 40U / μmol maltose respectively For the GP of trisaccharide, shake and react at 150rpm at 55°C for 30min, then add 2U / mLSP and 2000U / μmol maltotriose BE, shake and react at 55°C for 16h. After the reaction, the pH of the reaction mixture was adjusted to 4.5 with 2M HCl and heated at 100° C. for 30 min to terminate the reaction. After cooling to room temperature, centrifuge at 8000 g for 20 min, take the supernatant, dialyze in a 1 kDa dialysis bag at room temperature for 48 h, and freeze-dry to obtain a glycogen α-glucan (GnG) sample.

[0047] Table 1

[0048]

[0049] a The molar ratio of substrate sucrose and primer maltotriose;

[0050] b weight average molecular weight;

[0051] c Number average molecular

Embodiment 2

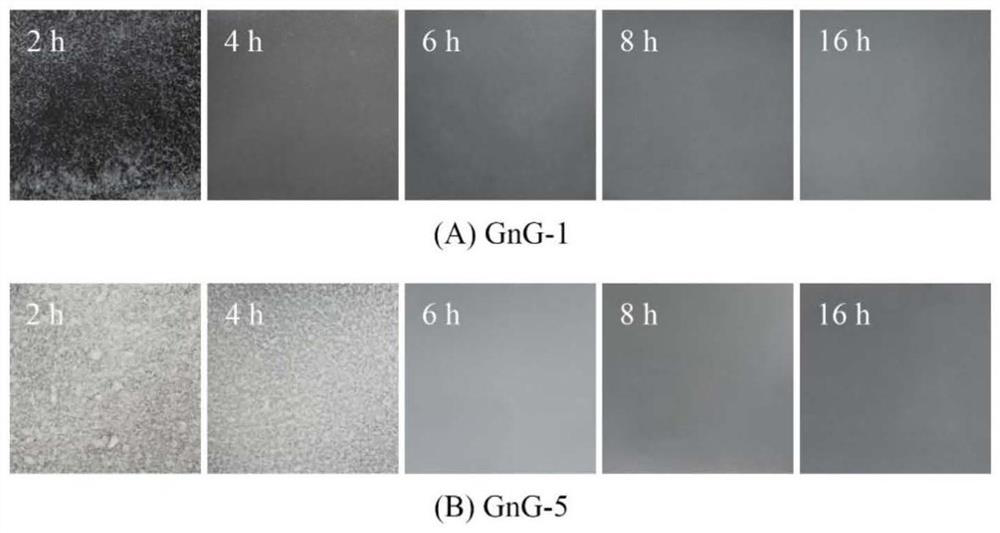

[0065] Embodiment 2: the influence of reaction time on GnG synthesis

[0066] (1) Preparation of GnG samples with different reaction times

[0067] In high concentration phosphate buffer (160mM KH 2 PO 4 and 240mM Na 2 HPO 4, pH=7.0) add 240mM sucrose and 0.4mM maltotriose (the molar ratio of sucrose to maltotriose is 600:1), and then add 5U / μmol maltotriose and 40U / μmol maltotriose respectively after incubation at 55℃ for 20min For sugar GP, shake and react at 150rpm at 55°C for 30min, then add 2U / mL SP and 2000U / μmol maltotriose BE, shake and react at 55°C. During this process, 10 mL of the reaction mixture was taken every 2 h, the pH of the reaction mixture was adjusted to 4.5 with 2M HCl and heated at 100° C. for 30 min to terminate the reaction. After cooling to room temperature, it was centrifuged at 8000g for 20min, and the supernatant was dialyzed in a 1kDa dialysis bag at room temperature for 48h. The results were as follows: image 3 Shown:

[0068] The s

Embodiment 3

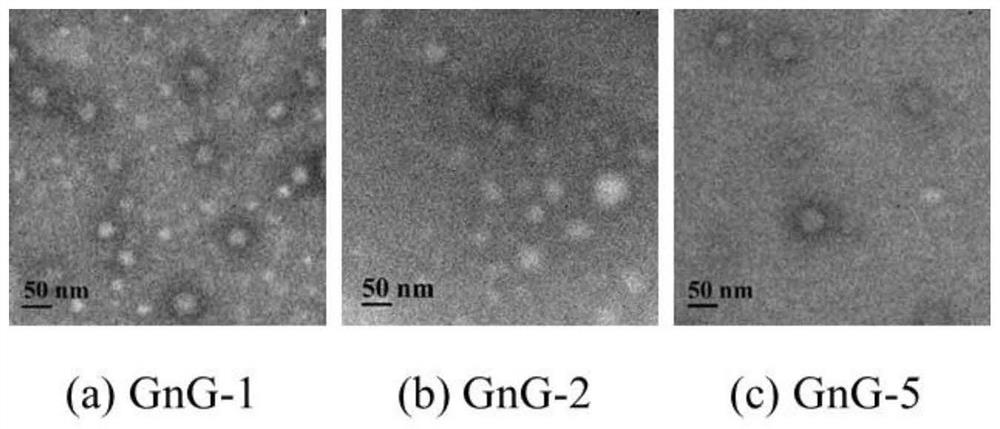

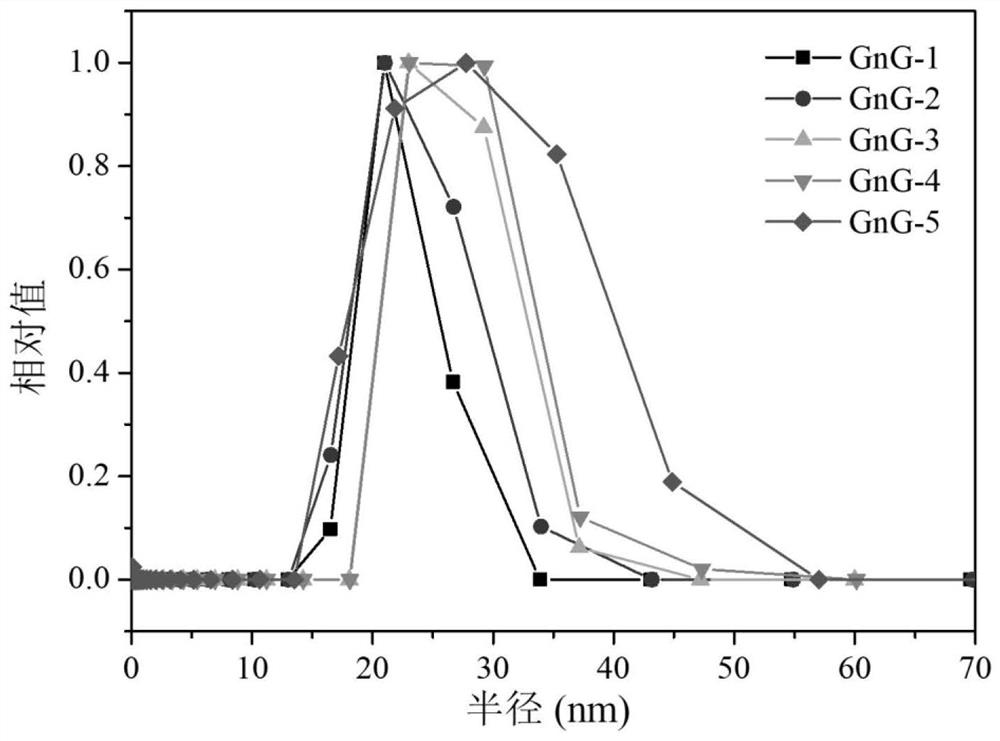

[0086] Embodiment 3: the fine structure analysis of GnG

[0087] (1) Analysis of α-amylase hydrolysis rate

[0088] GnG samples (10mg / mL in 0.2M sodium citrate buffer, pH 5.2, 1mM CaCl 2 ). The reaction products were collected at 0, 5, 10, 20, 30, 40, 50, 60, 90 and 120 min, respectively, and 9 volumes of absolute ethanol was added to terminate the reaction and centrifuged at 10000 g for 5 min. The amount of glucose released during the reaction was determined by GOPOD kit. The hydrolysis rate of α-amylase is calculated by the following formula, where G t is the amount of glucose released at t min, G 0 is the initial glucose content at 0min, S is the quality of the GnG sample, and the results are as follows Image 6 Shown:

[0089]

[0090] In the first 20min, with the increase of GP / BE ratio, the initial α-amylase hydrolysis rate of the sample increased. After 20min, GnG-1 and GnG-2 had a stable glucose release rate. In 20-40min, with the increase of GP / BE, the h

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap