Method for changing platinum channel convection in ultrathin flexible glass manufacturing

A flexible glass and platinum channel technology, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of slow precipitation and no effective control method for stones, and achieve the effect of improving streaks and reducing platinum defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

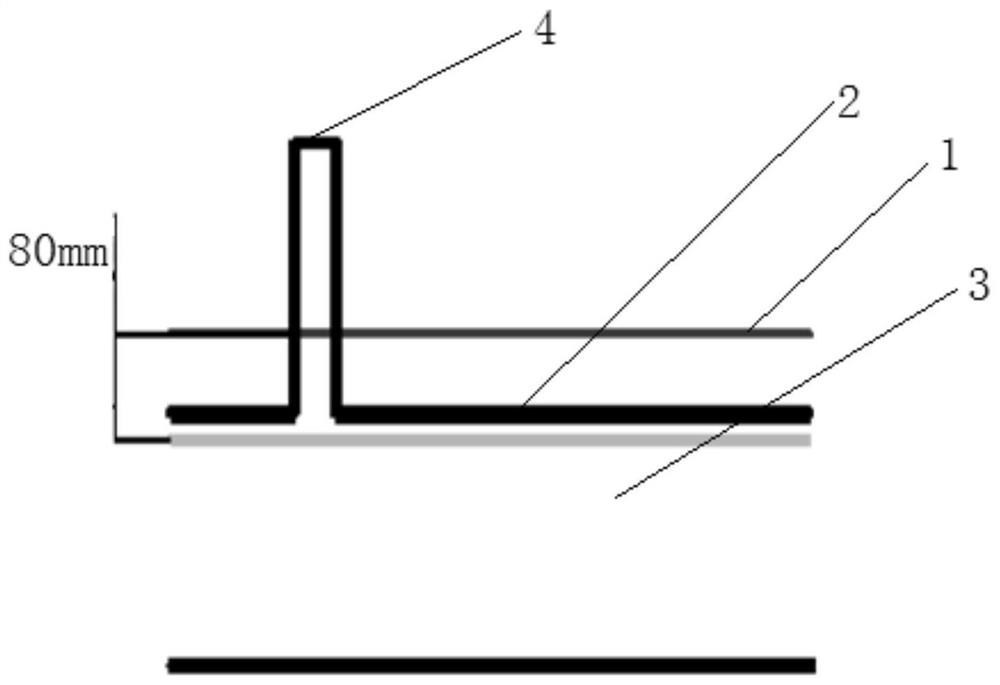

[0030] Such as figure 1 As shown, a method of changing the convection of the platinum channel in the manufacture of ultra-thin flexible glass includes the following content:

[0031] (1) Change the glass liquid level 1 in the convection process of the platinum channel 2;

[0032] (1.1) By changing the feeding amount, the difference between the feeding amount and the output amount is changed, so that the glass liquid level 1 is lowered by 80mm;

[0033] (1.11) Reduce the amount of feeding;

[0034] (1.12) Maintain normal lead-out volume;

[0035] (1.13) The difference between feeding and discharging makes the liquid level drop by 1.5mm / hr;

[0036] (1.14) The cooling section of the measuring part of the glass liquid level 1 is the liquid level port 4.

[0037] (1.2) Keep the lowered glass liquid level for 4 hours;

[0038] (1.21) According to the residence time of the glass liquid 3 in the cooling section of the platinum channel 2 is 2 hours, keep it for 4 hours to allow th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap