Spinel isopipe for fusion forming alkali containing glass sheets

A technology of melting glass and alkali metal, applied in glass forming, glass forming, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

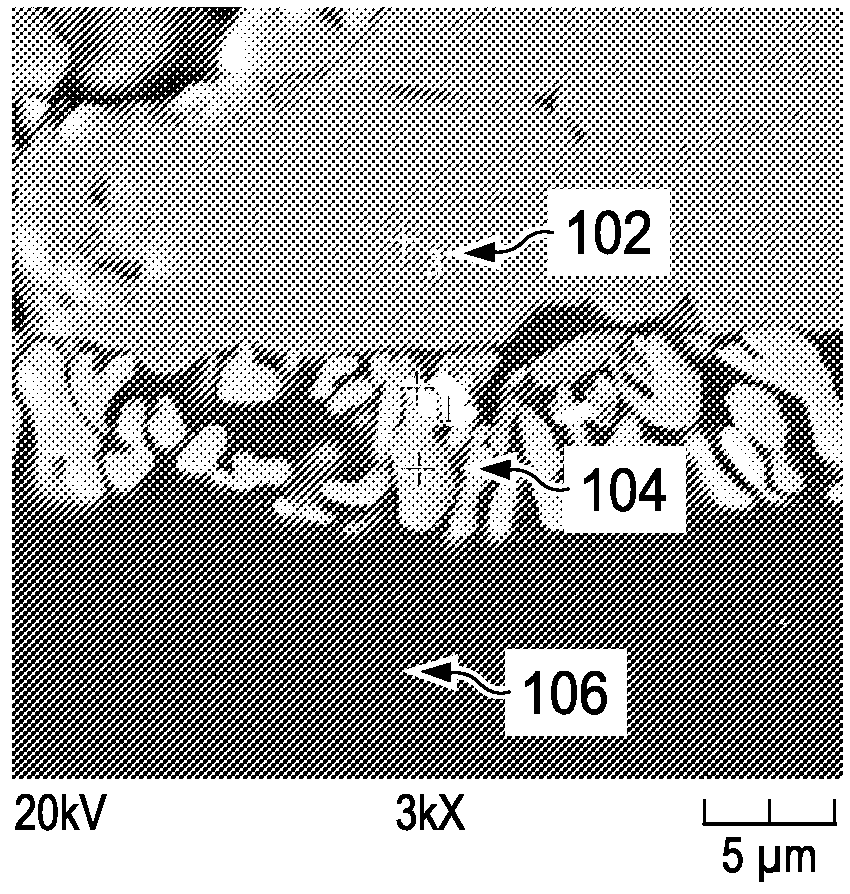

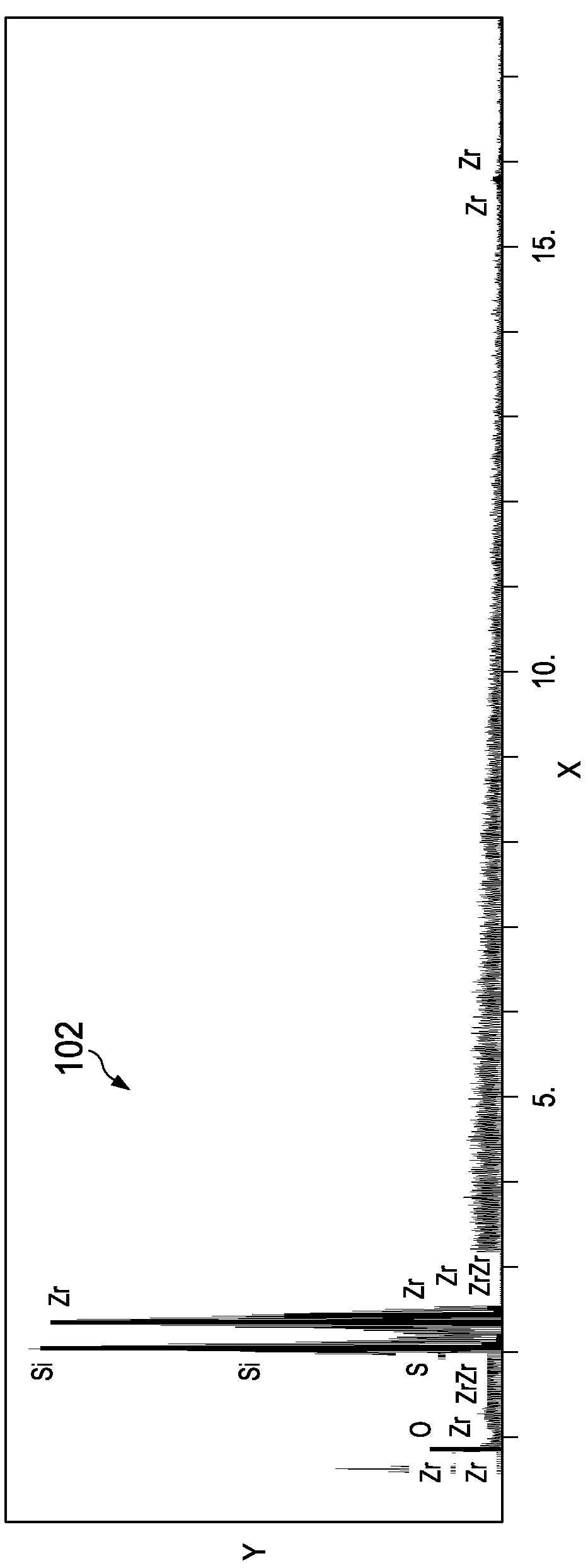

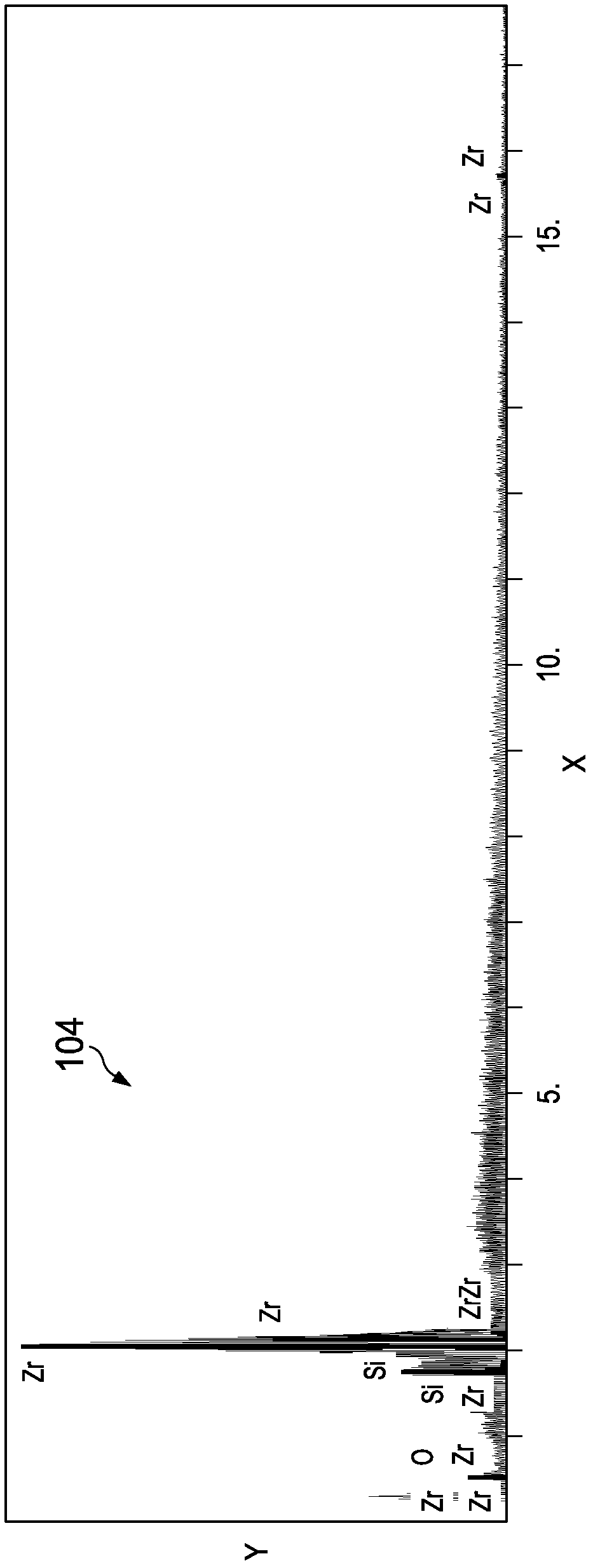

[0018] Before discussing the solution of the present invention, two tests are given which highlight the unfavorable reaction between zircon and alkali-containing glasses. The first test used a glass containing sodium (Na) and potassium (K) alkali metals (the composition of which is listed in Table 2) to conduct a zircon refractory belt test, in which a scanning electron microscope (SEM) image and two energy-dispersive X-ray spectra (EDX) based on the SEM images are shown in Figures 1A-1C. In FIG. 1A , a SEM image depicts zircon bands 102 and problematic dissociated zircon 104 (zirconia and silica) at the refractory interface with alkali-containing glass 106 . The problematic dissociated zircon 104 includes zirconia 104 and silica, wherein the silica dissolves into the alkali-containing glass 106 . In Figure 1B, the EDX spectrum for identifying the elemental composition of the zircon belt 102 is shown (note: in the EDX spectrum shown here, the x-axis represents the energy of x-ra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap