Fireproof distributed photovoltaic grid-connected cabinet

A distributed photovoltaic and network cabinet technology, applied in the field of grid-connected cabinets, can solve the problem of spontaneous combustion of electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

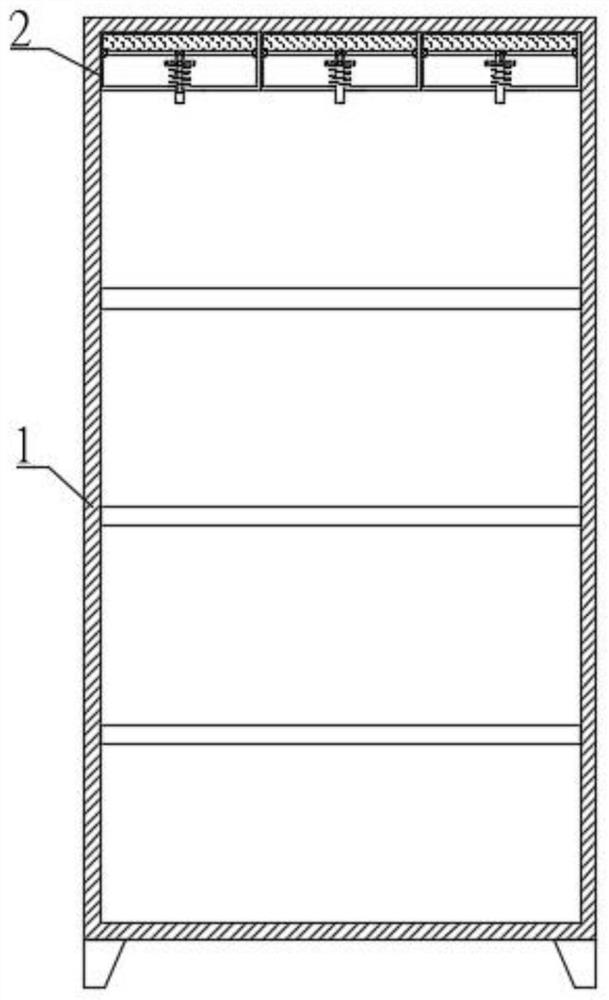

[0021] refer to Figure 1-3 , a fireproof distributed photovoltaic grid-connected cabinet, including a grid-connected cabinet 1, the grid-connected cabinet 1 can adopt a conventional rectangular cabinet structure on the market.

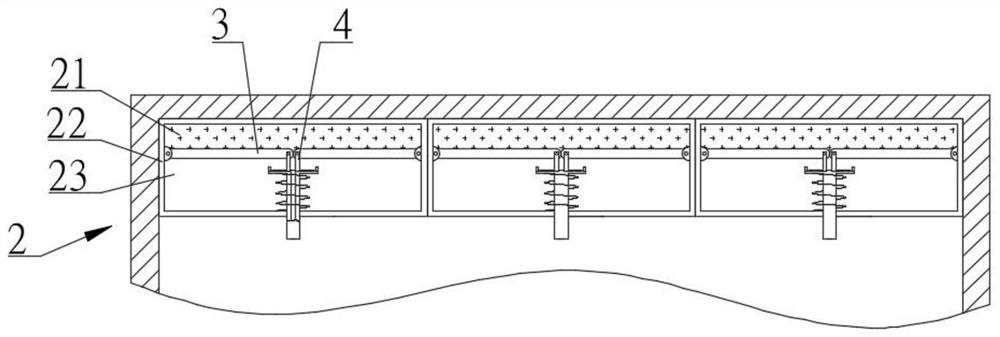

[0022] At least one fire extinguishing box 2 is arranged on the top of the grid-connected cabinet 1, and the fire extinguishing box 2 should be made of a metal material with good thermal conductivity.

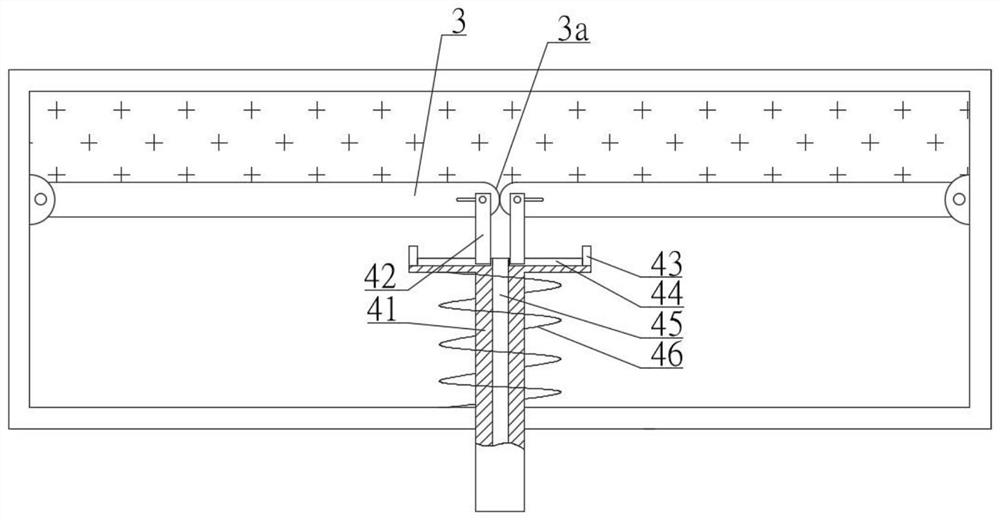

[0023] The fire extinguishing box is composed of a box body 22 , an upper cavity 21 and a lower cavity 23 , the upper cavity 21 and the lower cavity 23 are separated by the partition 3 , and the thermal expansion type fire extinguishing medium i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap