Surface plasma-based device capable of improving luminous efficiency of LED

A surface plasmon and luminous efficiency technology, applied in the field of optical communication, can solve the problems of few reports, low SPP conversion efficiency, reduced light extraction efficiency, etc., to achieve the effect of improving luminous efficiency, internal quantum efficiency and light extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Embodiment:

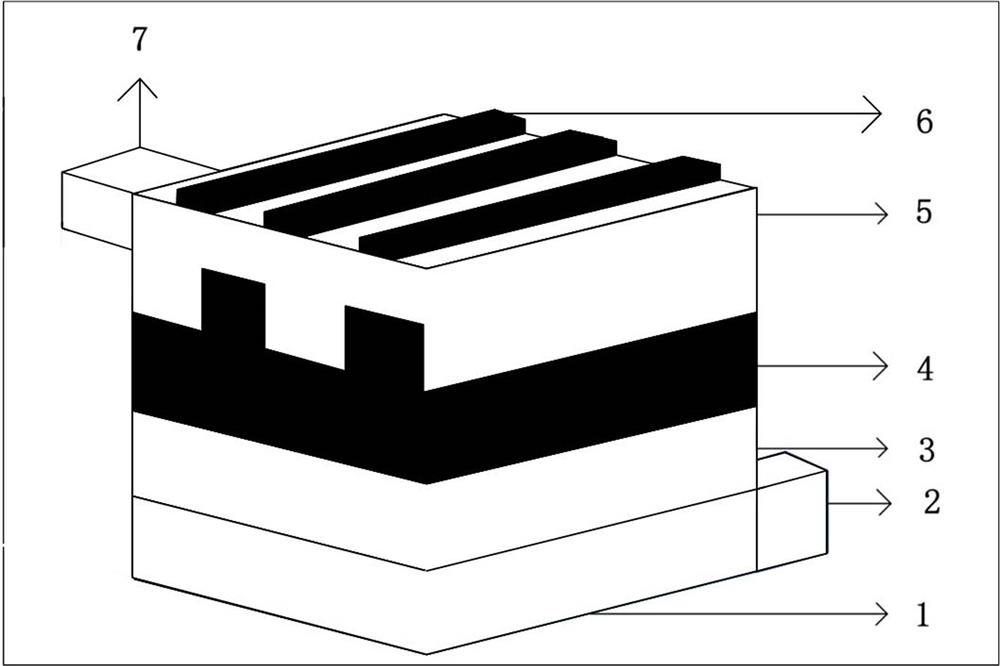

[0022] Refer figure 1 A device based on surface plasma energy can improve the LED luminous efficiency, including the N-pole gate layer 1, multi-quantian trap, MQWS layer 3, PV (Indium Tinoxides) , Referred to as ITO) buffer layer 5, the P magnetic gate layer 4 and the indium tin oxide ITO impingement 5 are in a grating ridge inserted, with a mosaic configuration, increase the contact area, improve the luminous efficiency, on the indium tin oxide buffer layer 5 The surface is provided with a uniform set of strip-shaped metal AG6, wherein the N-pole gate layer 1 and the edge of the indium tin oxide ITO impurity 5 are respectively provided with N electrodes N-NAD2 and P electrodes P-NAD7, N electrode N, respectively. -nad2 and p electrodes P-NAD7 are in a diagonal position in the device physics center.

[0023] The N polarity gate layer, and the P magnetic gate layer is gallium nitride GaN.

[0024] The multi-quantum well, that is, the multi-quantum well layer havin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap