Protective plate mechanism of automobile engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

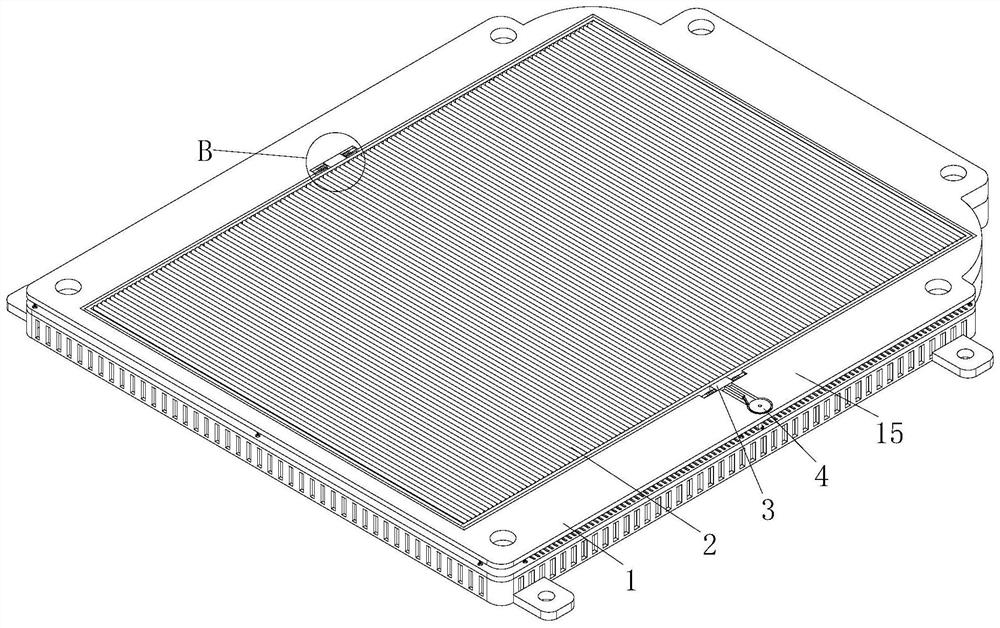

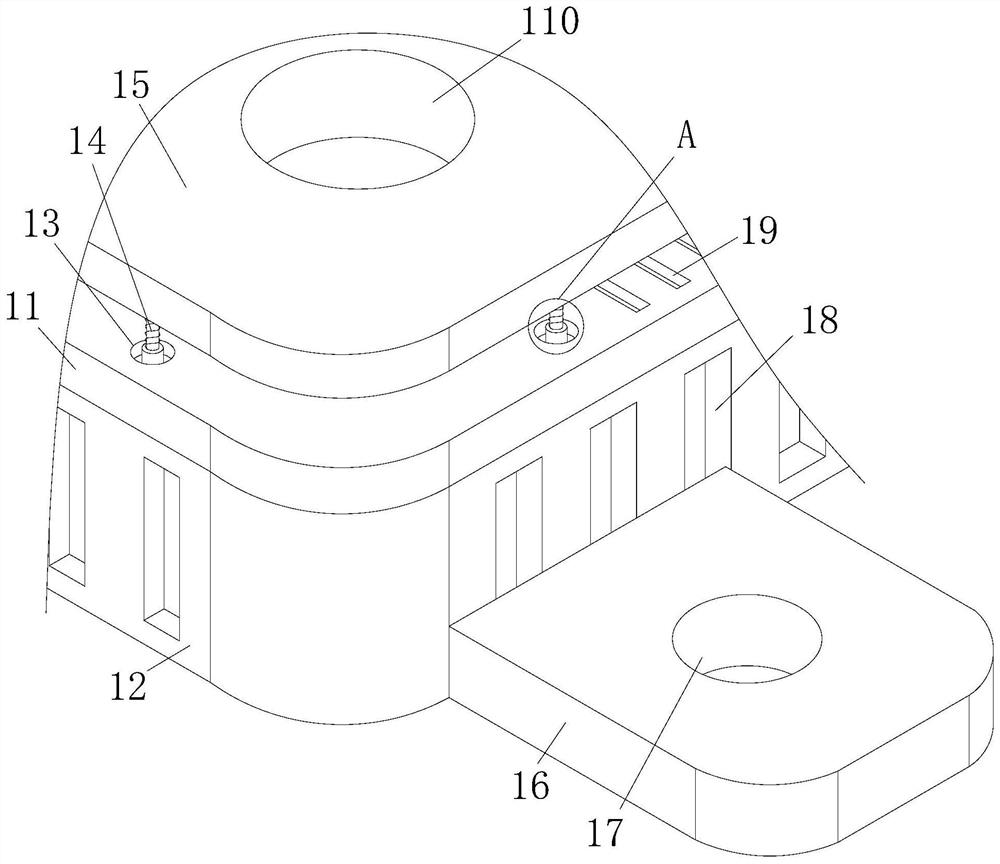

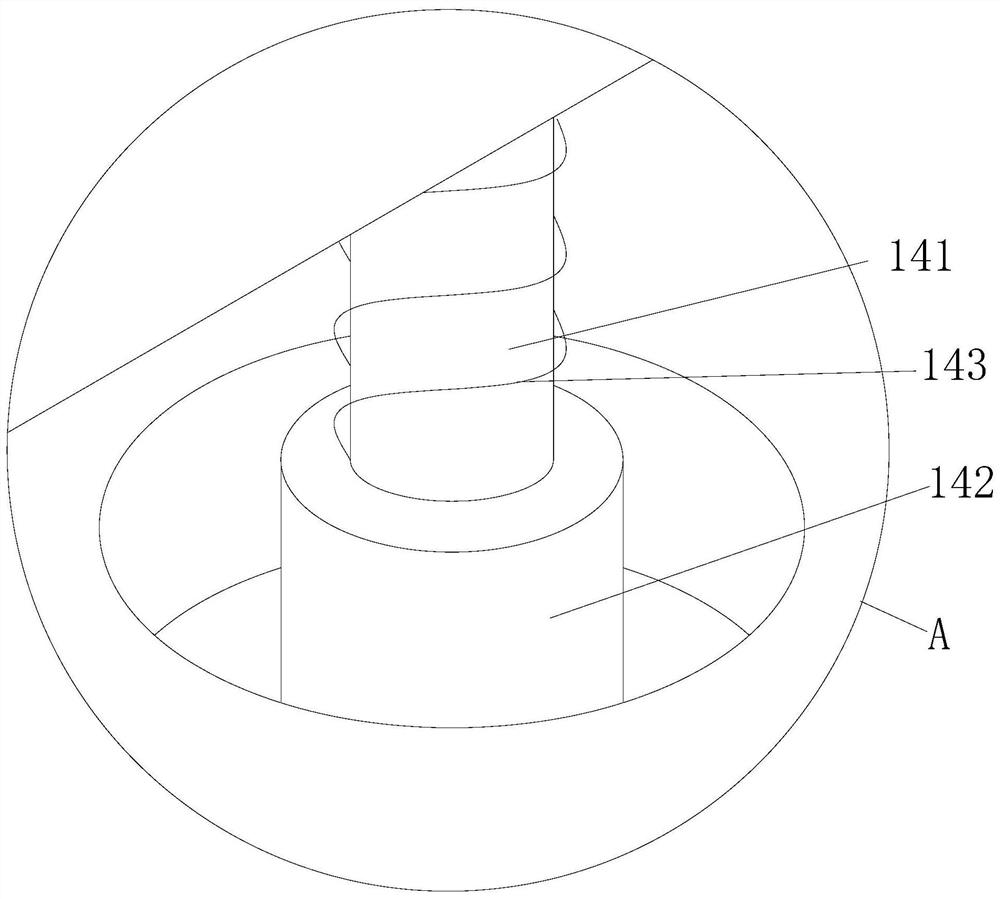

[0032] Attached below Figure 1-6 The present invention is further described with embodiment:

[0033] A guard plate mechanism for an automobile engine, comprising a guard plate mechanism 1, the guard plate mechanism 1 is arranged on an automobile chassis, and the guard plate mechanism 1 is covered outside the automobile engine. The present invention improves the existing guard plate structure, improves In the process of using the final guard plate, it can not only realize the effective protection of the car engine, but also play a role in heat dissipation during the protection function, and the improved equipment optimizes the structure of the guard plate , the optimized guard plate can effectively reduce the degree of wear of the guard plate during actual use, thereby prolonging the service life of the guard plate.

[0034]In this embodiment, the guard plate mechanism 1 includes a supporting guard plate 11 and a rectangular support frame 12, the supporting guard plate 11 and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap