Treatment method for reducing amount and pollution of yellow liquor of Maotai-flavor wine

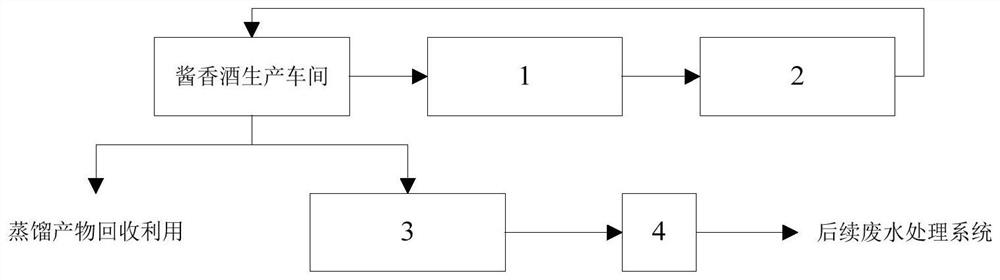

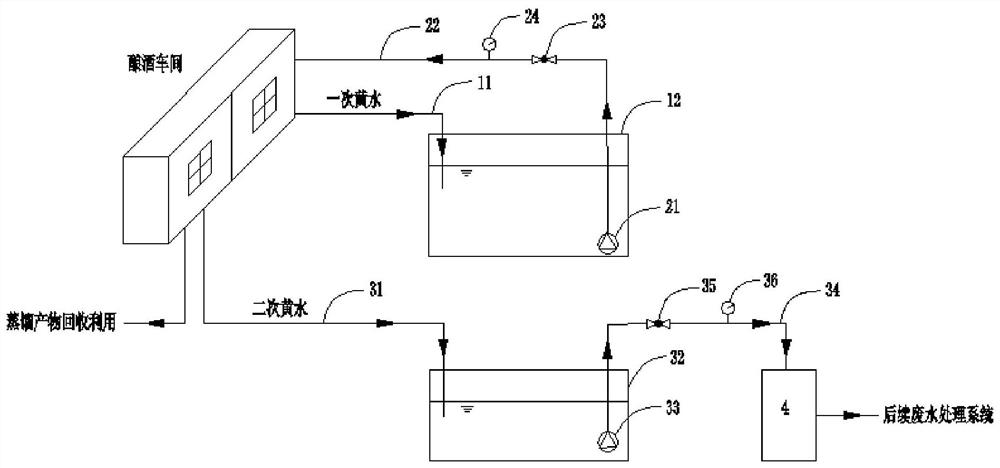

A treatment method, the technology of Maotai-flavored wine, applied in the field of Maotai-flavored wine yellow water reduction and pollution reduction treatment, can solve the problems of excessive water quality, impact of sewage treatment system, unsteady output speed and output, etc., to reduce workload and difficulty, ease the impact of water quality, and facilitate the effect of pollution treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Taking 300L yellow water as an example, the above system is used for processing. During distillation, the distillation method is to use 172°C hot steam to pass into the distillation pot of primary yellow water, and the organic matter in the yellow water is azeotropically brought out by the hot steam. ; The distillation product is cooled, collected, and recycled. The pressure of the hot steam is 0.7MPa. 3 The speed of / s continues to feed hot steam, and the time of hot steam feeding lasts for 35 minutes.

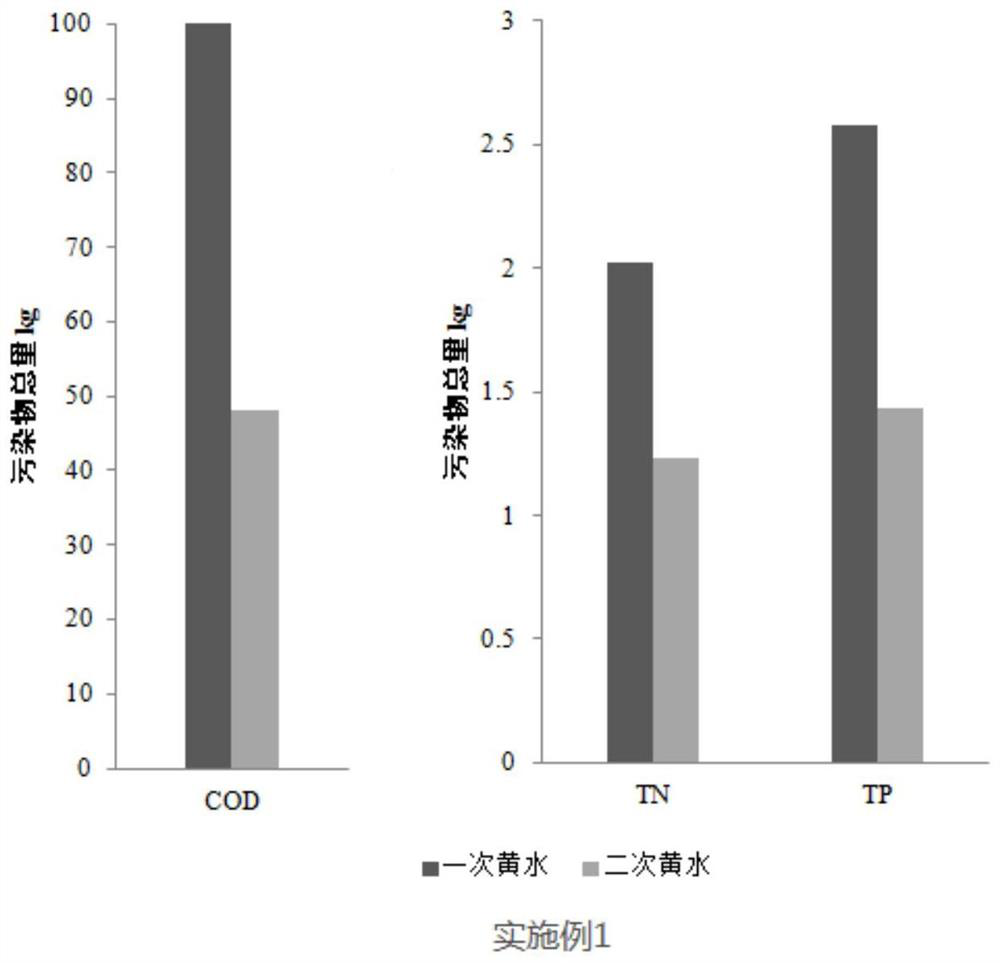

[0046] After distillation, the total amount of secondary yellow water collected is about 180L, and the reduction of yellow water wastewater reaches 40%. Sampling and analysis of COD changes in the secondary yellow water showed that the COD concentration decreased from 334,000mg / L to 267,500mg / L, the COD concentration reduction rate reached 19.9%, the total amount of COD decreased from 100.2kg to 45.4kg, and the total COD reduction amount reached 54.6%. At the same

Embodiment 2

[0048] Taking 300L yellow water as an example, the above system is used for processing. During distillation, the distillation method is to use 170°C hot steam to pass into the distillation pot of primary yellow water, and the organic matter in the yellow water is azeotropically brought out by the hot steam. ; The distillation product is cooled, collected, and recycled. The pressure of the hot steam is 0.8MPa, and it is 3 The speed of / s is continuously fed into the hot steam, and the time of feeding the hot steam lasts for 30 minutes.

[0049] After distillation, the total amount of secondary yellow water collected is about 170L, and the reduction of yellow water wastewater reaches 43.3%. Sampling and analysis of COD changes in the secondary yellow water showed that COD decreased from 340500mg / L to 278500mg / L, the COD concentration decreased by 18.2%, the total amount of COD decreased from 102.1kg to 47.345kg, and the total reduction of COD reached 53.63%. At the same time

Embodiment 3

[0051] Taking 300L yellow water as an example, the above system is used for processing. During distillation, the distillation method is to use 175°C hot steam to pass into the distillation pot of primary yellow water, and the organic matter in the yellow water is azeotropically brought out by the hot steam. ; The distillation product is cooled, collected, and recycled. The pressure of the hot steam is 0.8MPa, and it is 3 The speed of / s is continuously fed into the hot steam, and the time of feeding the hot steam lasts for 45 minutes.

[0052] After distillation, the total amount of secondary yellow water collected is about 145L, and the reduction of yellow water wastewater reaches 51.6%. Sampling was carried out to analyze the change of COD in the secondary yellow water. The COD decreased from 367500mg / L to 273000mg / L, with a drop rate of 25.7%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap