Machining method for producing seamless aluminum pipe through common extruder

A technology of seamless aluminum tube and processing method, used in metal extrusion, metal processing equipment, metal extrusion dies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

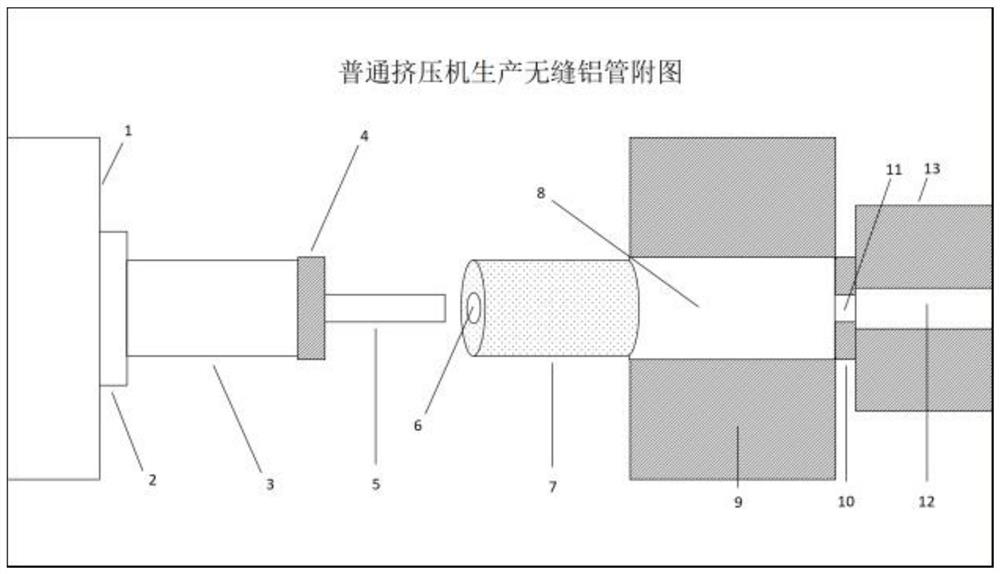

Image

Examples

Embodiment 1

[0024] A processing method for producing seamless aluminum tubes with an ordinary extruder of the present embodiment comprises the following steps:

[0025] S1: Based on the existing extrusion production line, replace the extrusion rod and supporting mold to produce seamless aluminum tubes;

[0026] S2: Using the inner and outer diameters of the produced seamless aluminum tubes, the stroke of the main cylinder, and the inner hole size of the ingot barrel, process the extrusion rod and supporting molds, and simulate the piercing extrusion method;

[0027] S3: The extruded rod includes the first part of the main rod and the second part of the auxiliary rod; the diameter of the main rod is the same as the original extruded rod except for the thick diameter, and the auxiliary rod and the main rod are processed in one piece, and the diameter of the auxiliary rod is equal to the formed seamless aluminum inner diameter of the tube;

[0028] S4: The outer diameter of the matching mold i

Embodiment 2

[0038] A processing method for producing seamless aluminum tubes with an ordinary extruder of the present embodiment comprises the following steps:

[0039] S1: Based on the existing extrusion production line, replace the extrusion rod and supporting mold to produce seamless aluminum tubes;

[0040] S2: Using the inner and outer diameters of the produced seamless aluminum tubes, the stroke of the main cylinder, and the inner hole size of the ingot barrel, process the extrusion rod and supporting molds, and simulate the piercing extrusion method;

[0041] S3: The extruded rod includes the first part of the main rod and the second part of the auxiliary rod; the diameter of the main rod is the same as the original extruded rod except for the thick diameter, and the auxiliary rod and the main rod are processed in one piece, and the diameter of the auxiliary rod is equal to the formed seamless aluminum inner diameter of the tube;

[0042] S4: The outer diameter of the matching mold i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap