Alkali metal carbon preparation device in supercritical fluid reaction system

A supercritical fluid and reaction system technology, applied in the field of base metal carbon preparation devices in supercritical fluid reaction systems, can solve problems such as low conversion rate of photocatalytic reduction of CO2, and achieve the advantages of preventing instability, improving efficiency and increasing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

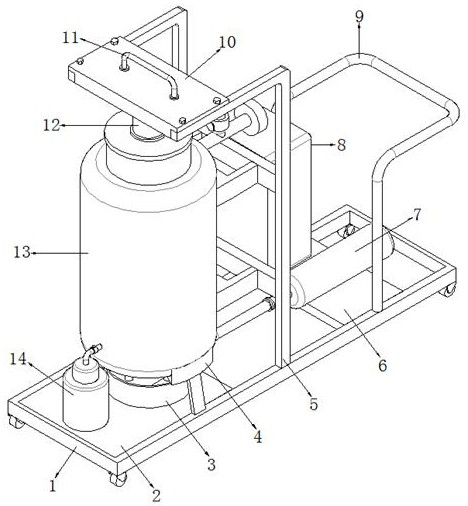

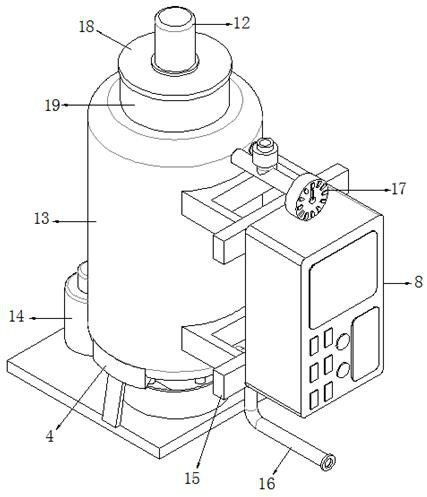

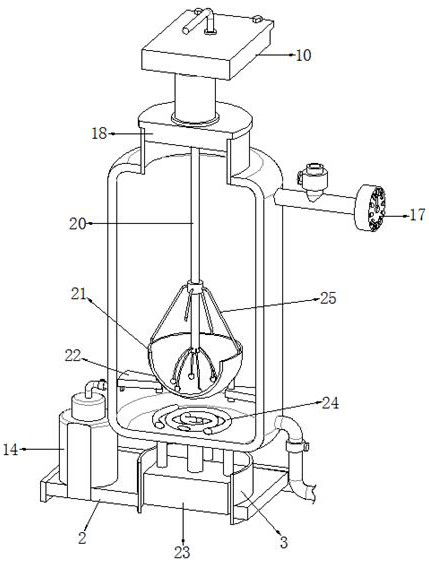

[0030] Refer Figure 1-4 A supercritical fluid reaction system, alkali-based metal carbon preparation device, including the bottom frame 1, welded the L-shaped bracket 5 on both sides of the bottom frame 1 near the intermediate position, and one side welding of the L-bracket 5 has two The mounting frame 15, one side of the mounting frame 15 is connected by a bolt, and a heating mechanism is provided at the bottom of the reaction barrel 13, and the top welding of the reaction tub 13 is welded to the entry and exit tube 19, and the top of the entry and exit tube 19 is inserted with a seal. The cover 18, the top of the sealing cover 18 is connected to the motor 12 by a bolt, and the output shaft of the motor 12 welcomes the rotating shaft 20, and the outer wall of the rotating shaft 20 welded to the bearing housing, the outer wall of the bearing housing welded with an equal distance distribution connecting rod 25, connecting rod The bottom of the 25 is connected by a b

Example Embodiment

[0039] Example 2

[0040] Refer Figure 5 In a supercritical fluid reaction system, alkali-base metal carbon preparation devices, this embodiment, compared to the first embodiment, the bottom inner wall of the bottom frame 1 is connected to the heat transfer cover 28 wrapped in periphery of the heating coil 24, and thermally conductive The cover 28 is provided as a spherical structure.

[0041] Working principle: When using the user, the user can heat the CO2 and the heating coil 24 via the heater 23 and the heating coil 24 to isolate the CO2 and the heating coil 24 by the heat shield 28 to avoid the direct and heating plates of CO2. A sharp expansion problem occurs when the tube 24 is in contact, preventing an unstable problem due to changes in the gas pressure inside the reacted barrel 13.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap