Anti-unscrewing bolt

An anti-return wire and bolt technology, applied in the directions of bolts, screws, nuts, etc., can solve problems such as abnormal operation of equipment, lack of mature solutions, damage, etc., and achieve a wide range of applications and ideal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

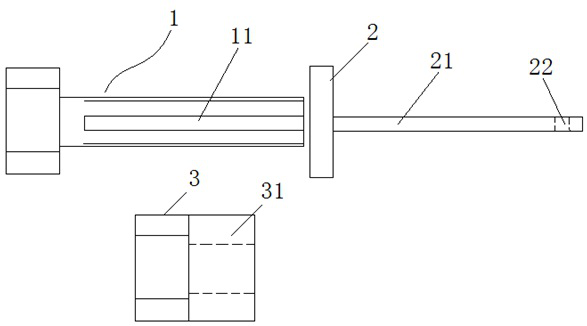

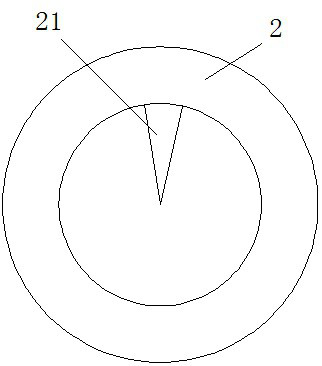

[0018] Such as figure 1 , 2 The shown anti-retraction bolt includes a bolt body 1, an anti-retraction gasket 2, and a nut 3. A wedge strip 21 that is gradually thickened from the gasket end to the suspended end is arranged on the anti-retraction gasket 2. The unsupported end of 21 is provided with a wedge-removing hole 22 for removing the wedge strip 21 . A wedge groove 11 is opened on the threaded rod of the bolt to form a wedging structure with the wedge strip 21 of the anti-retreat washer 2 . When the anti-retraction gasket 2 is sleeved on the threaded rod of the bolt, the nut 3 is tightened, the wedge strip 21 enters the wedge groove 11 and as the anti-retraction gasket 2 approaches the bolt head, the wedge strip 21 gradually contacts with the wedge The grooves 11 cooperate to form a tension structure.

[0019] The wedge groove 11 is an equal width groove, and the wedge strip 21 is a non-equal width strip. The section width of the wedge strip on the side of the anti-retrea

Embodiment 2

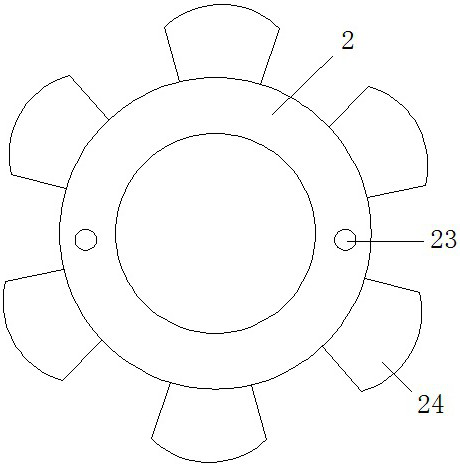

[0023] Such as image 3 An anti-retraction bolt shown includes a bolt body 1 and an anti-retraction gasket 2, two positioning pins 23 are arranged on the anti-retraction gasket 2 and on a diameter line, and on the side wall of the anti-retraction gasket 2 Six positioning plates 24 are evenly distributed.

[0024] One end of the positioning pin 23 is installed on the end face of the anti-back gasket 2, and the other end is suspended; one end of the positioning plate 24 is installed on the outer wall of the anti-back gasket 2, and the other end is suspended; Set in the pin hole on the end face of the fixed part, the free end of the positioning plate is inserted into the slot provided by the bolt head or covers the bolt head, so that the anti-return gasket, the bolt and the fixed part form an anti-rotation structure .

[0025] The thread withdrawal caused by vibration must make the bolt rotate, and the anti-rotation structure limits the bolt from rotating, which solves the problem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap