Method for producing edible straw by twin-screw extruder

A twin-screw extruder, straw technology, applied in the direction of food coating, application, food science, etc., can solve problems such as human harm, waste, environmental pollution, etc., to ensure uniformity, avoid waste, and enhance waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

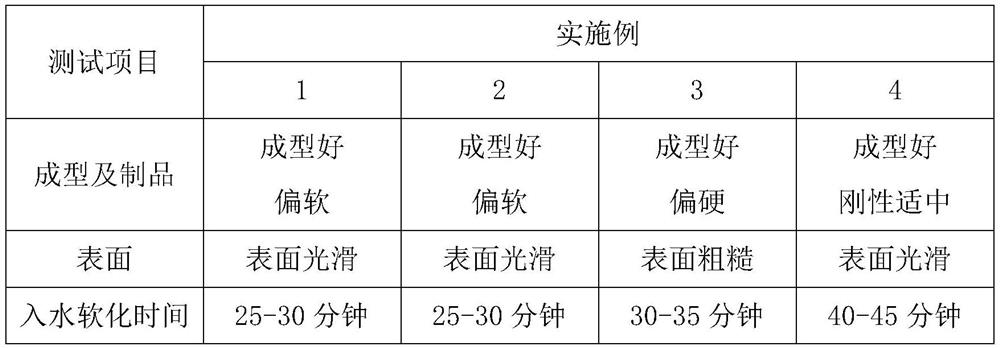

Embodiment 1

[0027] A method for producing edible straws with a twin-screw extruder, comprising the following steps:

[0028] Slurry production, dilute 25 parts of pear residue after juicing with water, put it into a beater for beating treatment, filter the residue with a 150-mesh filter, add 2 parts of agar powder and appropriate amount of water after filtering, stir and heat to 71°C , forming a fruit and vegetable slurry with a water content of 24%;

[0029] The materials are mixed, the fruit and vegetable slurry is put into a mixer, and 80 parts of cornstarch, 0.1 part of citric acid, 0.1 part of natural essence, 2 parts of xylitol and appropriate amount of water are put in successively, and stirred for 5 minutes to prepare A mixture with a water content of 10%;

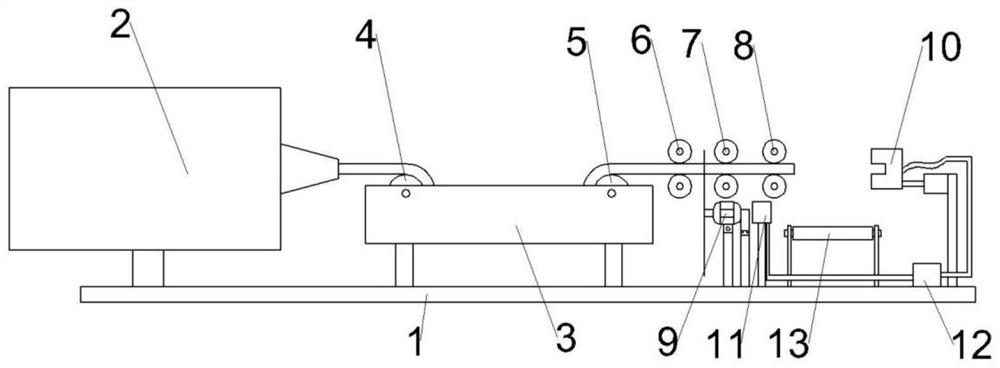

[0030] Extrusion molding, putting the compound into a twin-screw extruder for extrusion molding to form a tube blank;

[0031] coating, immersing the tube blank in edible gelatin liquid, so that the outer surface of the tube bl

Embodiment 2

[0040] A method for producing edible straws with a twin-screw extruder, comprising the following steps:

[0041] Slurry production, dilute 40 parts of pear dregs after juicing with water, put them into a beater for beating treatment, filter the residue with a 150-mesh filter, add 4 parts of carrageenan powder and appropriate amount of water after filtering, stir and heat to 76 °C to form a fruit and vegetable slurry with a water content of 22%;

[0042] The materials are mixed, the fruit and vegetable slurry is put into a mixer, 85 parts of cornstarch, 0.5 part of citric acid, 0.5 part of natural essence, 3 parts of xylitol and appropriate amount of water are put in successively, and stirred for 15 minutes to prepare A mixture with a water content of 7%;

[0043] Extrusion molding, putting the compound into a twin-screw extruder for extrusion molding to form a tube blank;

[0044] coating, immersing the tube blank in edible gelatin liquid, so that the outer surface of the tube

Embodiment 3

[0051] A method for producing edible straws with a twin-screw extruder, comprising the following steps:

[0052] Slurry production, dilute 60 parts of apples after juicing with water, put them into a beater for beating treatment, filter the residue with a 150-mesh filter, add 6 parts of pectin powder and appropriate amount of water after filtering, stir and heat to 80°C , forming a fruit and vegetable slurry with a water content of 20%;

[0053] The materials are mixed, the fruit and vegetable slurry is put into a mixer, and 85 parts of cornstarch, 0.1 part of citric acid, 0.1 part of natural essence, 1 part of xylitol and appropriate amount of water are put in successively, and stirred for 20 minutes to prepare A mixture with a water content of 6%;

[0054] Extrusion molding, putting the compound into a twin-screw extruder for extrusion molding to form a tube blank;

[0055] coating, immersing the tube blank in edible gelatin liquid, so that the outer surface of the tube blank

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap