Plate transfer assisting equipment based on visual induction

A technology for plate transfer and auxiliary equipment, which is applied in the direction of television, transportation and packaging, closed-circuit television system, etc., can solve the problems of inability to detect in time, loss, etc., and achieve the effect of being beneficial to protection, reducing physical consumption and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] In order to deepen the understanding of the present invention, the present invention will be further detailed in connection with the examples and the drawings, which are not intended to be construed as limiting the scope of the invention.

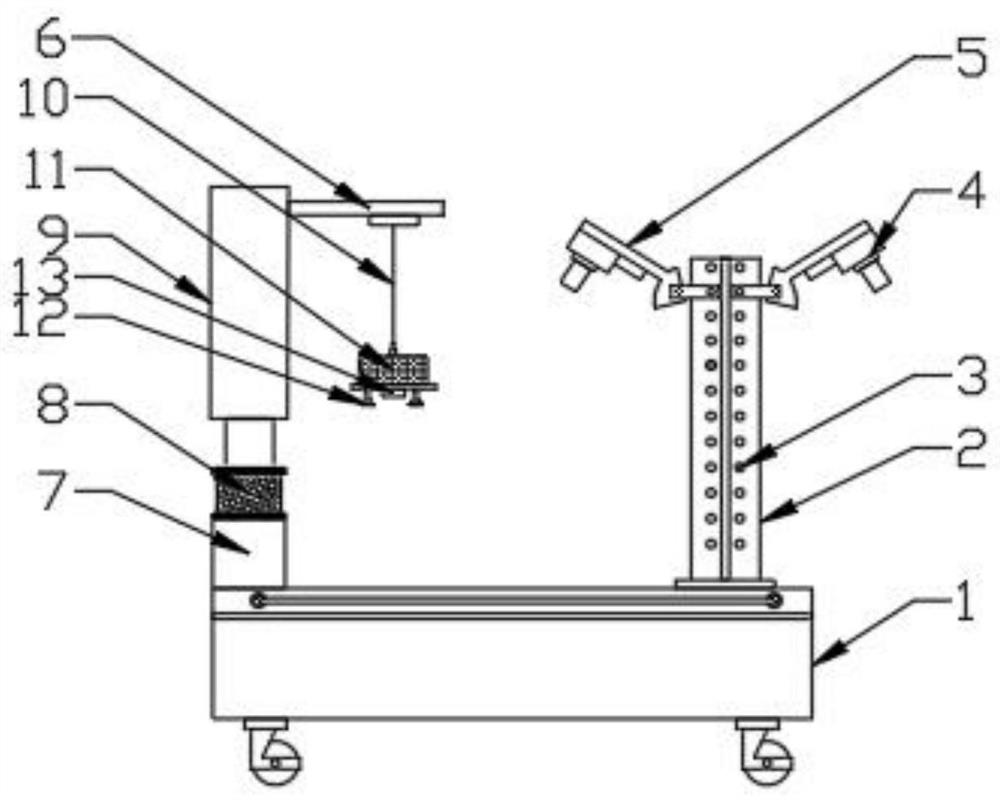

[0016] like figure 1 Shown, based on visual perception of the auxiliary sheet transport apparatus, comprising a box body 1, the fixed rod 2, bolt holes 3, 4 cameras, camera holder 5, hanging rod 6, rotation means 7, drives the lifting device 8, the main fixed rod 9, strap 10, the vacuum suction unit 11, the chuck 12, the gravity sensor 13.

[0017] Based on visual perception of the auxiliary sheet transport device comprising a tank body and a plurality of cameras holder 5, on the left side surface of the vehicle body 1 is provided with a swivel device box 7, the rotary top drive apparatus 7 through elevating device 8 and the bottom of the main fixing bar 9 is connected to the upper end of the main fixing bar 9 is provided with a left hangin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap