Anti-explosion low-energy-consumption type low-temperature sludge drying granulation process

A technology of sludge drying and low energy consumption, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low heat and moisture exchange efficiency, reduced energy efficiency of system operation, and low moisture content of dried sludge, achieving Improve heat and moisture exchange efficiency, strengthen heat and moisture transfer, and improve the effect of heat and moisture exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

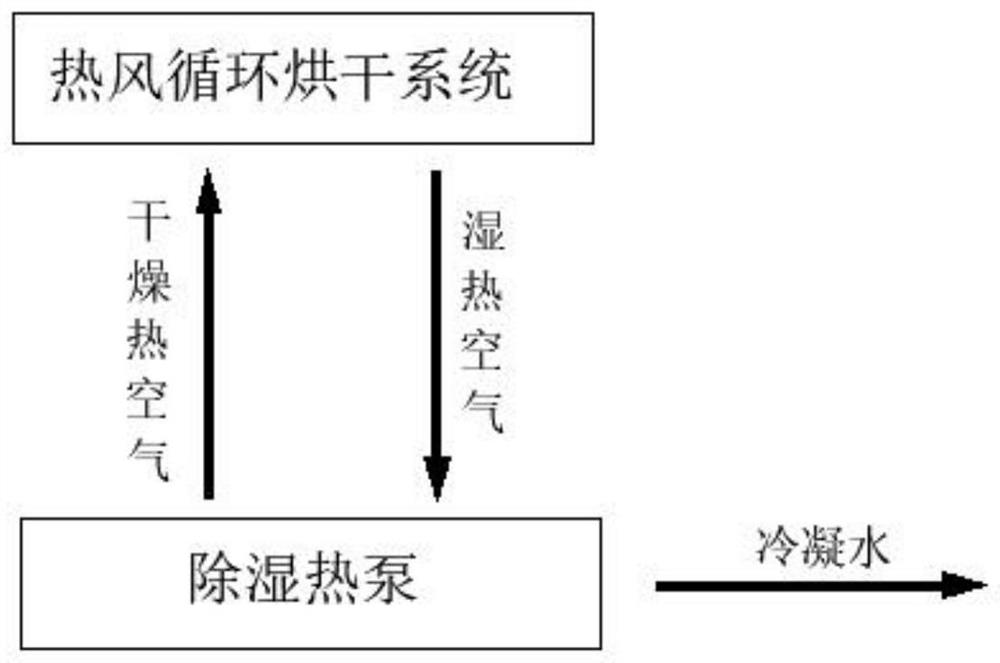

[0044] An explosion-proof low-energy low-temperature sludge drying and granulation process is composed of a hot air circulation drying system and a bipolar heat pump dehumidification system.

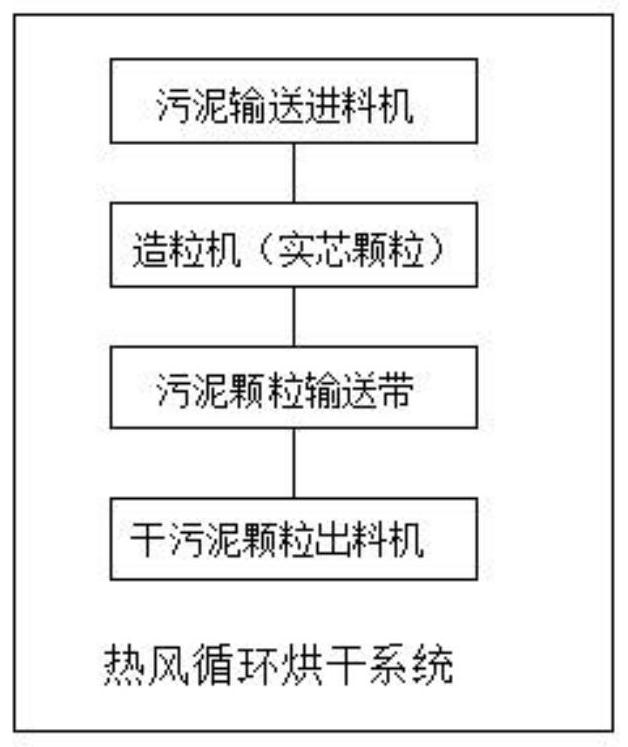

[0045] Among them, the hot air circulation drying system includes a sludge conveying feeder, a granulator, a sludge particle conveyor belt, a stirring fan, an activated carbon air filter, and a dry sludge particle discharger;

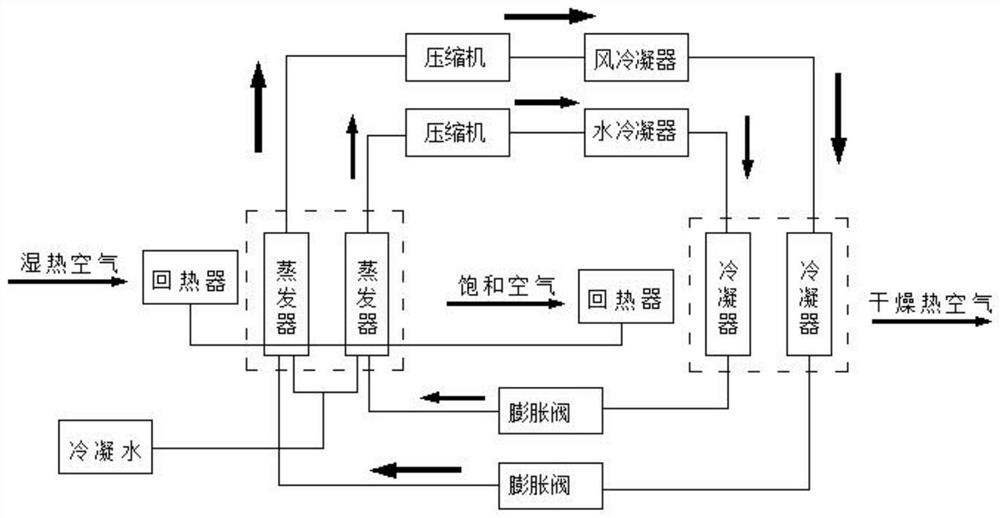

[0046] The bipolar heat pump dehumidification system includes a high temperature side heat pump dehumidification system and a low temperature side heat pump dehumidification system;

[0047] The high temperature side heat pump dehumidification system is composed of a high temperature side compressor, a high temperature side plate water-cooled condenser, a high temperature side evaporator, a high temperature side expansion valve, a high temperature side heating heat exchanger, and a high temperature side hot water circulating pump;

[0048] The low-temperature side he

Embodiment 2

[0050] The bipolar heat pump dehumidification system also includes a heat recovery system, which is composed of a heat recovery device and a heat recovery circulating water pump, which is used for precooling of hot humid air and preheating of low temperature saturated air.

Embodiment 3

[0052] Based on embodiment 1,2, further, each equipment parameter in the technique is carried out optimized design, as follows:

[0053] The granulator granulates into hollow granules, and the shape of the granules is selected from but not limited to hollow cylinder, hollow prism, hollow circular truncated hollow prism, hollow truncated prism, preferably hollow cylinder. Specifically, the specific surface area of the hollow particles can be designed according to equipment power and product requirements, and is not limited here.

[0054] The circulating medium in the tube of the high temperature side evaporator is R134a, and the circulating medium in the tube of the low temperature side evaporator is R22; the circulating medium in the tube of the high temperature side heating heat exchanger and the low temperature side heating heat exchanger is water.

[0055] The high-temperature side heating heat exchanger and the low-temperature side heating heat exchanger tubes are all made

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap