Safe and energy-saving comprehensive utilization system for boiler

A safety and boiler technology, applied in the treatment of combustion products, combustion methods, heat exchangers, etc., can solve problems such as blockage, aggravate heating surface wear, increase fly ash hardness, etc., to ensure safety, adjust flexibility, and improve economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

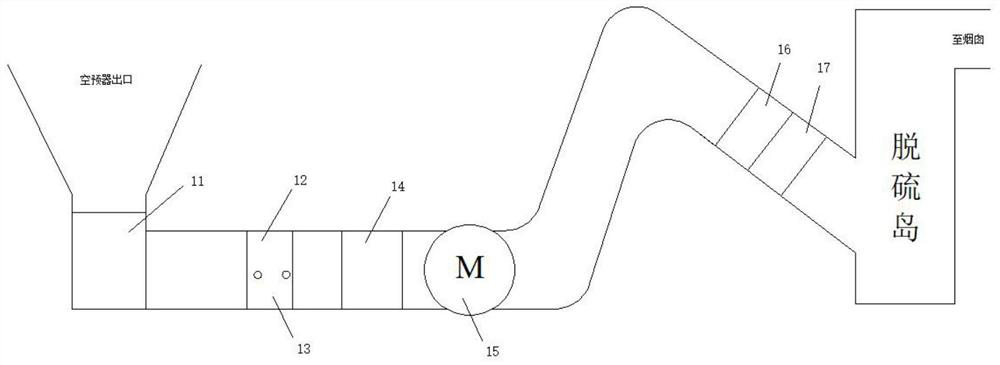

[0046] This embodiment provides a safety and energy-saving comprehensive utilization system for boilers, which mainly includes a flue gas heat release system, a waste heat utilization cycle heat exchange system, and a hot air heating system. Each system is described in further detail below.

[0047] 1. Flue gas heat release system

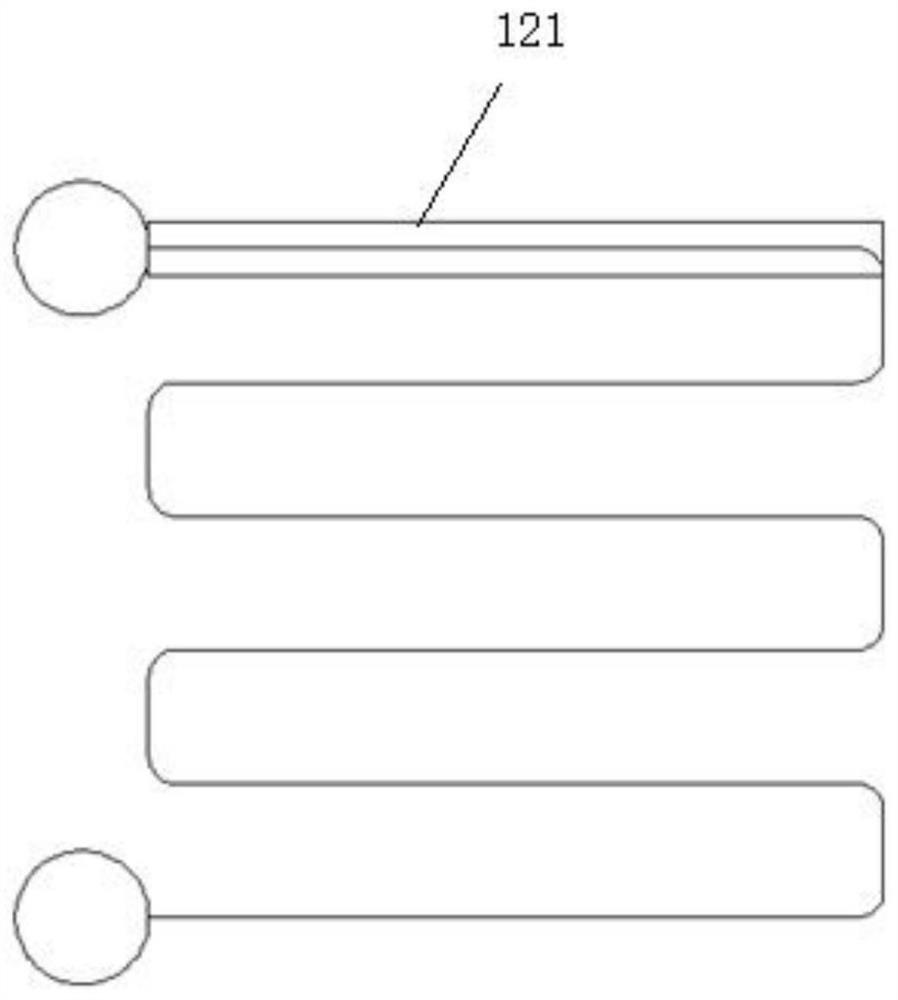

[0048] ginseng figure 1 As shown, the flue gas heat release system consists of a fly ash separator 11, a pre-dust collector heat exchanger 12 (including a soot blower 13), a primary heat exchanger 16 of the flue gas heat protection system in front of the desulfurization island, and a heat exchanger 16 in front of the desulfurization island. The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap