Transverse anti-symmetric elastic wave excitation device and preparation method

An antisymmetric, elastic wave technology, applied in the direction of the fluid using vibration, can solve the problems of multi-functional device design and experimental verification difficulties, and achieve the effect of simple structure and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

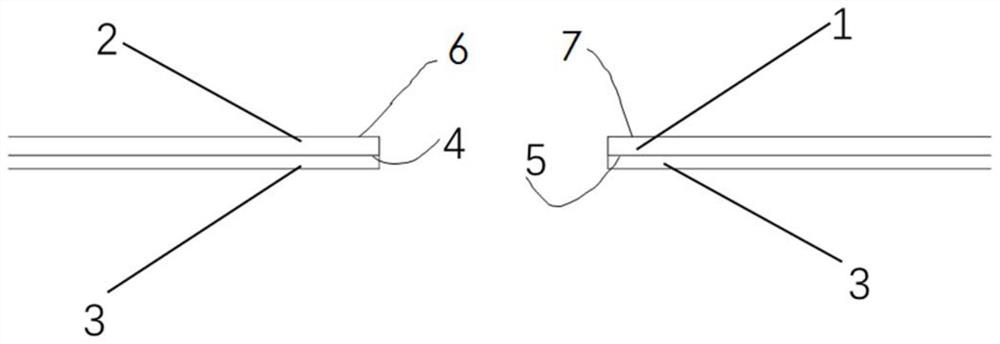

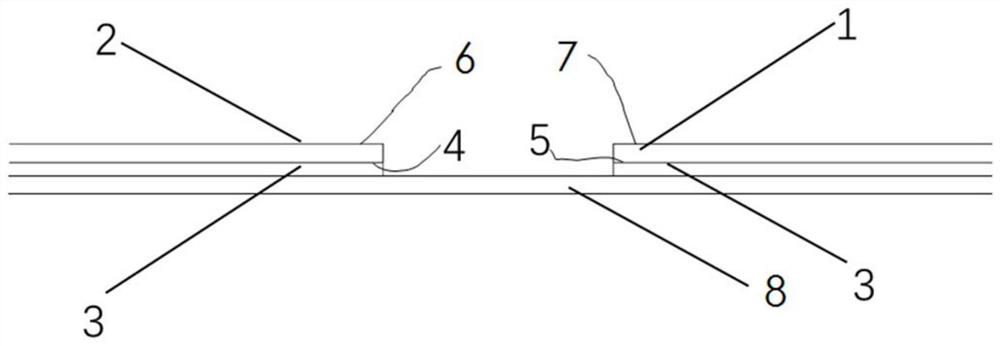

[0039] The present invention provides a transverse antisymmetric elastic wave excitation device, which includes a piezoelectric vibration component, a connection fixture 3 , a wiring group of the piezoelectric vibration component, and an installation base 8 .

[0040] Such as figure 1 As shown, the piezoelectric vibration component includes a first piezoelectric electret film 1 and a second piezoelectric electret film 2, in order to ensure that the materials of the first piezoelectric electret film 1 and the second piezoelectric electret film 2 The same, the same size, the same polarization direction, and the same processing technology, the same piece of piezoelectric electret film is cut laterally from the middle, and the first piezoelectric electret film 1 and the second piezoelectric electret film 2 Arranged according to the short side alignment, the piezoelectric electret film is made of irradiation cross-linked polypropylene piezoelectric electret film, the dimensions of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap