Adjustable intelligent pouring distributing device for high piers and tower columns

An adjustable and distributor technology, which is applied in construction, bridge parts, erection/assembly of bridges, etc., can solve the problems of unsatisfactory height, wide pouring range, labor-intensive and other problems, so as to improve construction efficiency, facilitate flexible dispersion and uniformity Convenience in pouring and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

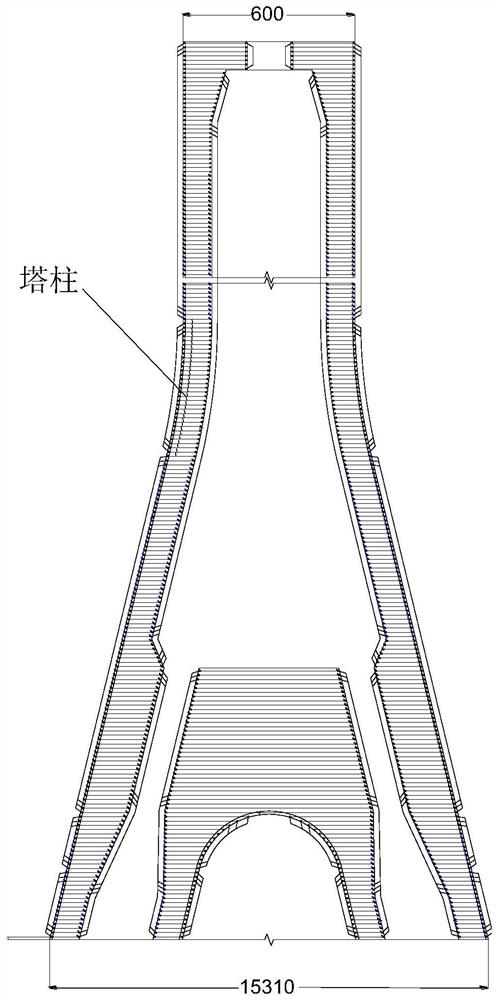

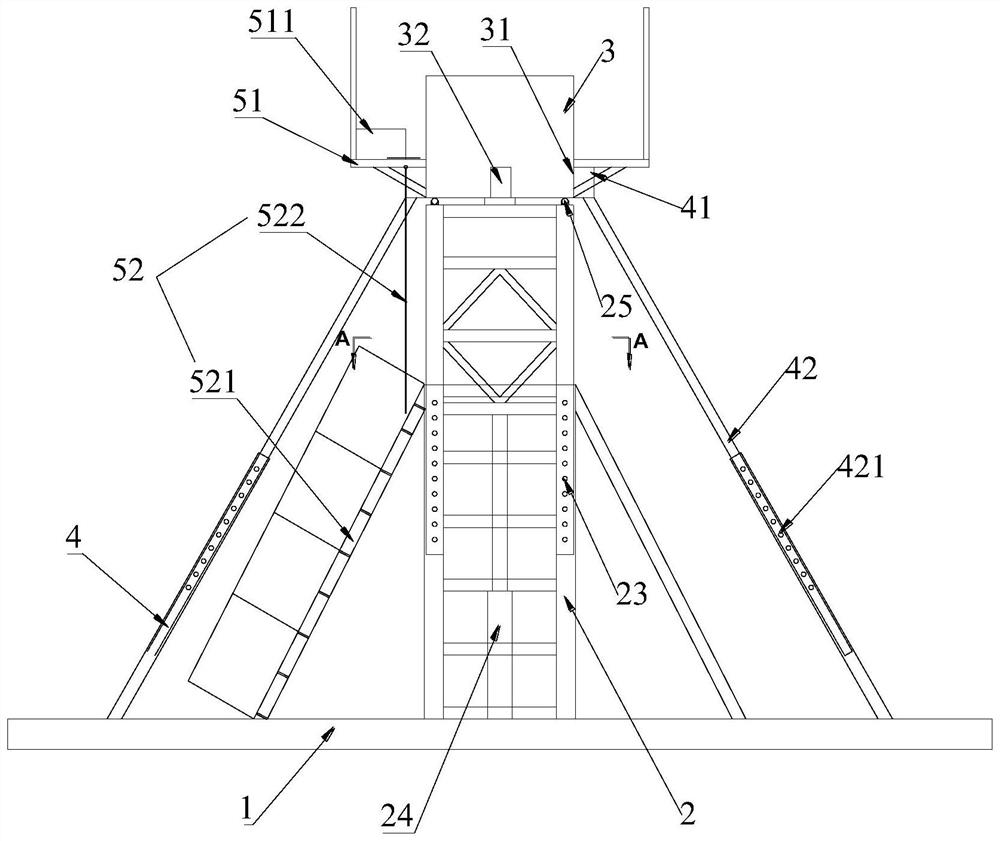

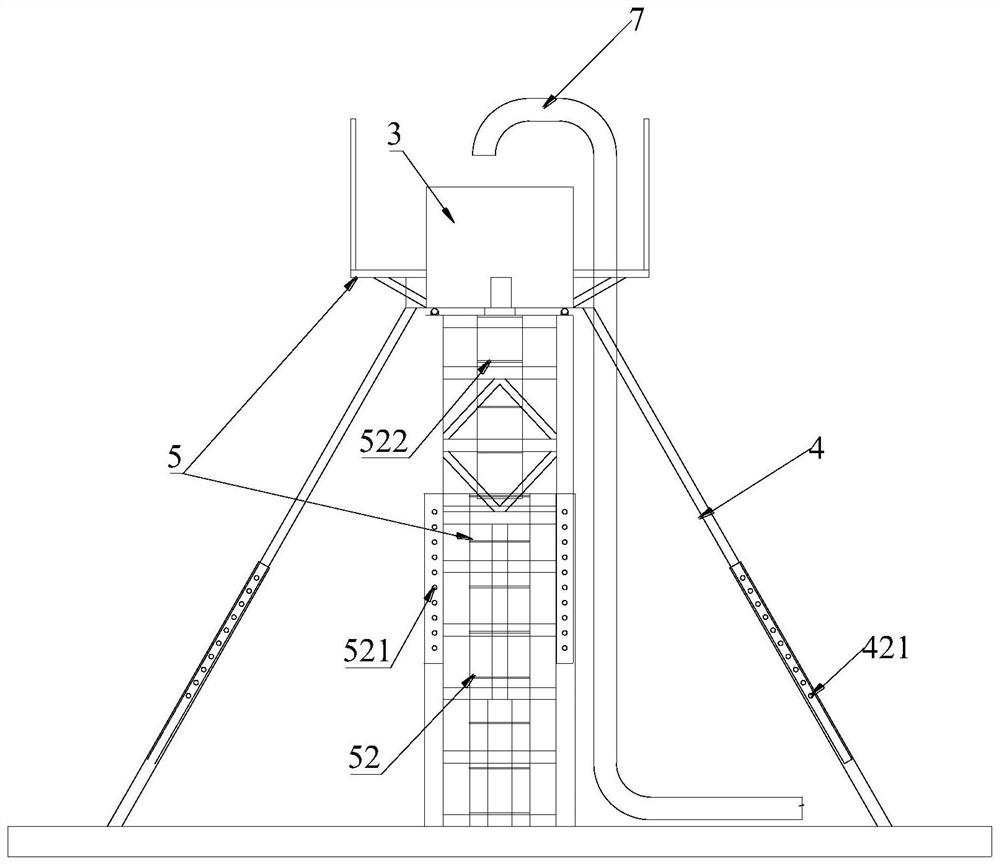

[0038] The height of the main tower of Mingguang Jiashan Avenue Project is 107.8m. The tower columns are divided into lower tower column, middle tower column and upper tower column from bottom to top. If the requirements cannot be met, it is necessary to use ground pumps to install pump pipes along with tower columns for pouring.

[0039] When the ground pump is used to pour the high-altitude tower column, the discharge port of the pump pipe is generally lengthened manually and the pump pipe is moved to pour the construction. This method is time-consuming, labor-intensive, and high-altitude operation construction has safety risks. At the same time, the section from the tower column to the upper tower column in the project is combined into a single tower by the tower limbs on both sides. The section of the tower column is constantly changing, and the longest section width gradually changes from 15.31m to 6m; the minimum section size is 6m*6m, and the pouring range is wide. When po

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap