Wet coal sample mixing rotary division machine

A shrinking machine and sample mixing technology, applied in the preparation of test samples, etc., can solve problems such as inability to divide materials evenly, inconvenient transportation, and increased production burden, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

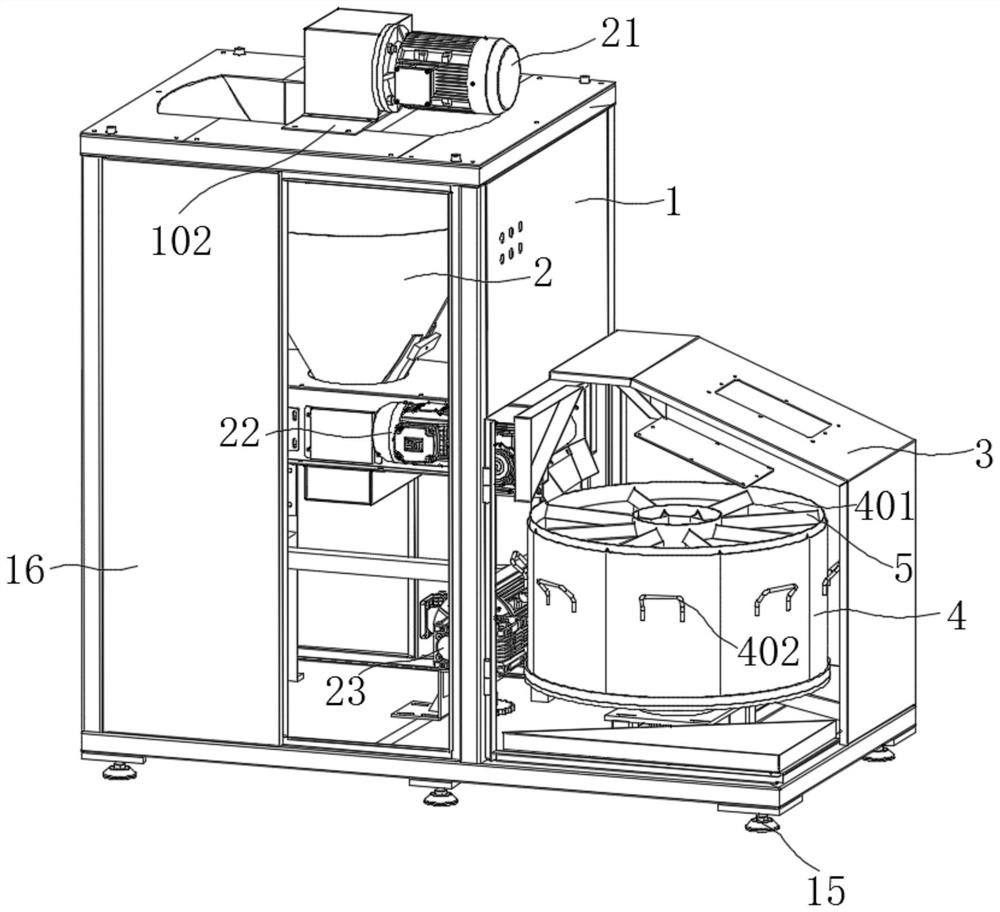

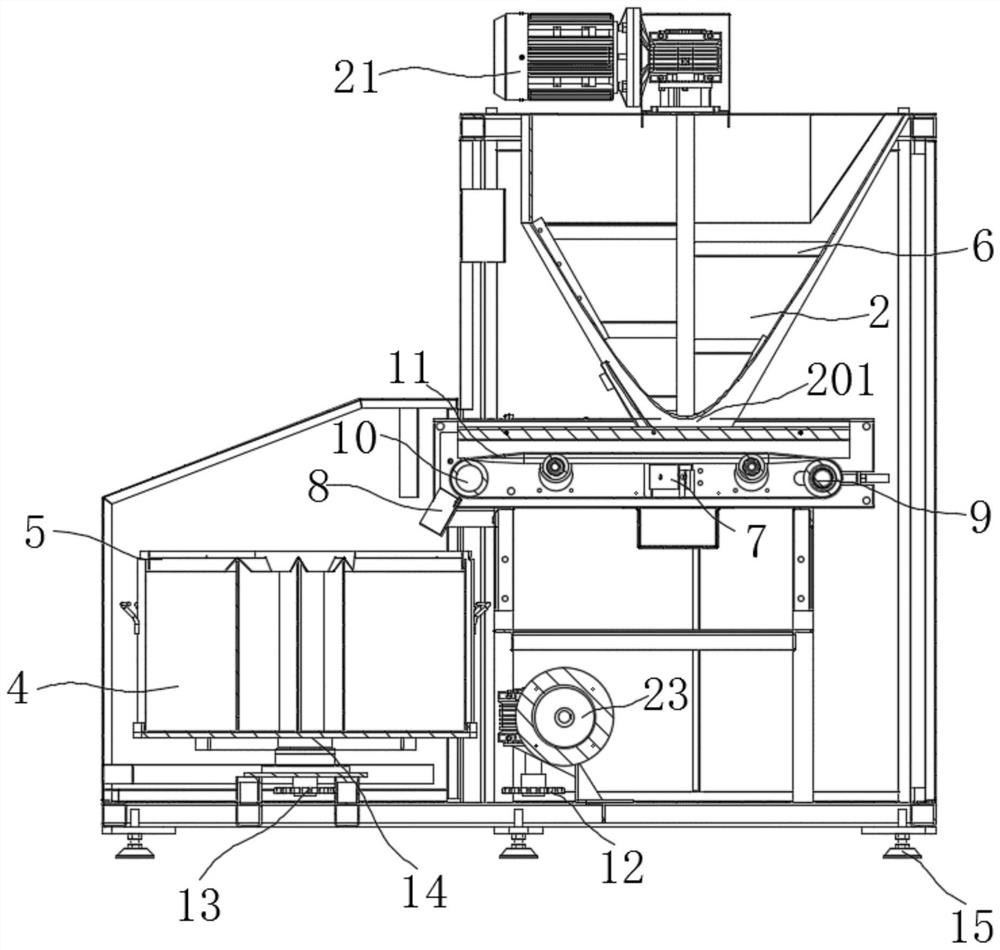

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] Such as Figure 1-5 As shown, a kind of wet coal sample mixing rotary shrinkage machine provided by the present invention includes a mixing casing 1, a mixing funnel 2 is arranged inside the mixing casing 1, and a discharge outlet is arranged at the lower end of the mixing funnel 2. Material port 201, the lower side of the discharge port 201 is provided with a conveyor belt 11; scraper plate 7, the scraper plate 7 is fixedly installed on the inner wall of the mixer shell 1 side, the scraper plate 7 is located between the upper and lower conveyor belts of the conveyor belt 11, and the outer wall on one side is in contact with the lower conveyor belt; the r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap