Bio-based high-temperature-resistant flame-retardant epoxy resin and preparation method thereof

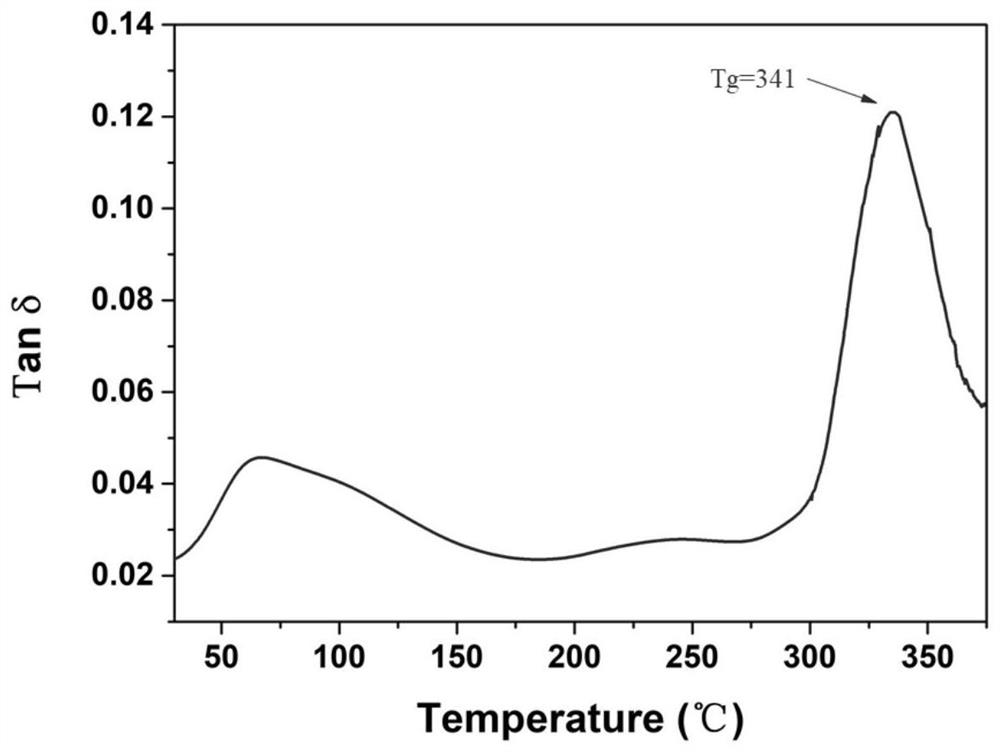

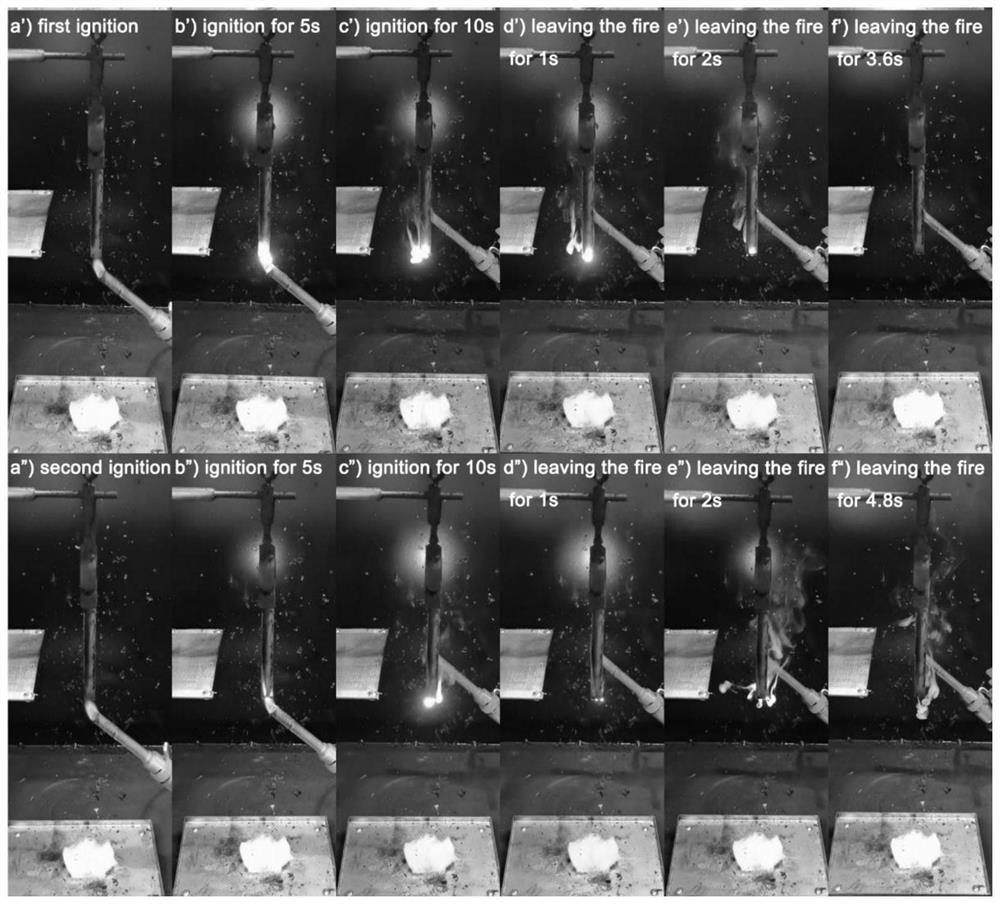

An epoxy resin and high-temperature-resistant technology, which is applied in the field of bio-based high-temperature-resistant flame-retardant epoxy resin and its preparation, can solve the problems of complicated preparation methods and poor high-temperature resistance performance, and achieve simple preparation process and improved high-temperature resistance performance , the effect of good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

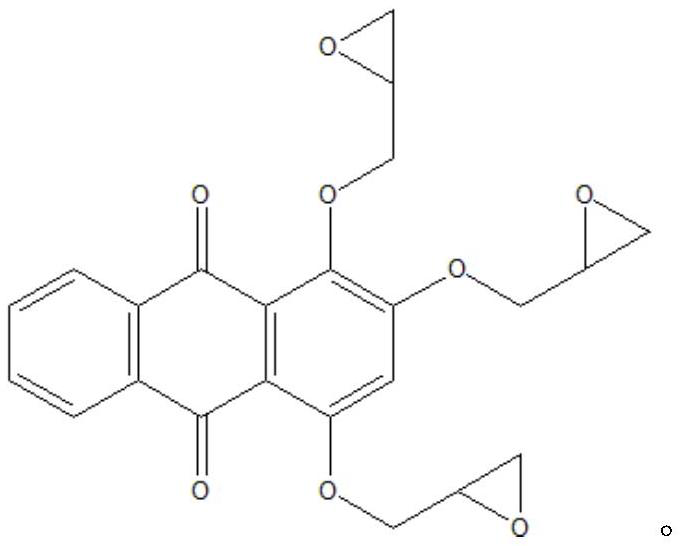

[0032] A preparation method of a bio-based high-temperature-resistant flame-retardant epoxy resin, comprising the steps of:

[0033] (1) Under nitrogen protection, mix hydroxylizarin, epichlorohydrin and co-solvent evenly and heat to 65-70°C, then add sodium hydroxide and tetramethylammonium bromide, hydroxylizarin, epichlorohydrin, The mass ratio of cosolvent, sodium hydroxide and tetramethylammonium bromide is 50~55:600~605:205~215:95~100:2~2.5; cosolvent is selected from methyl isobutyl ketone, acetone, One of the methyl ethyl ketones; stop the reaction after reacting at 65-70°C for 4-6 hours, remove the reaction residue by centrifugation, and collect the supernatant; pour the supernatant into a separatory funnel, add an equal mass of organic solvent to carry out Extract for 18-24 hours, the organic solvent is toluene or methyl isobutyl ketone; the system is washed several times with deionized water, the organic phase on the upper layer of the separatory funnel is separated, a

Example Embodiment

[0036] Example 1:

[0037] A preparation method of a bio-based high-temperature-resistant flame-retardant epoxy resin, comprising the steps of:

[0038](1) Under the protection of nitrogen, mix hydroxylizarin, epichlorohydrin and methyl ethyl ketone evenly and heat to 65-70°C, then add sodium hydroxide and tetramethylammonium bromide, hydroxylizarin, epoxy The mass ratio of chloropropane, methyl ethyl ketone, sodium hydroxide and tetramethylammonium bromide is 54:608:210:98:2.16; stop the reaction after reacting at 65-70°C for 5 hours, remove the reaction residue by centrifugation, and collect the upper layer clear liquid; pour the supernatant liquid into the separatory funnel, add equal mass of toluene to extract for 20h; wash the system several times with deionized water, separate the organic phase on the upper layer of the separatory funnel, and finally pass the organic phase by rotating Evaporator decompression distillation to obtain hydroxy madderin epoxy compound;

[0039

Example Embodiment

[0040] Example 2:

[0041] A preparation method of a bio-based high-temperature-resistant flame-retardant epoxy resin, comprising the steps of:

[0042] (1) Under the protection of nitrogen, mix hydroxylizarin, epichlorohydrin and methyl ethyl ketone evenly and heat to 65-70°C, then add sodium hydroxide and tetramethylammonium bromide, hydroxylizarin, epoxy The mass ratio of chloropropane, methyl ethyl ketone, sodium hydroxide and tetramethylammonium bromide is 50:600:205:95:2; stop the reaction after reacting at 65-70°C for 4 hours, remove the reaction residue by centrifugation, and collect the upper layer Supernatant liquid; Pour the supernatant liquid into the separatory funnel, add the same mass of methyl isobutyl ketone to extract 18h; wash the system several times with deionized water, separate the organic phase on the upper layer of the separatory funnel, and finally The organic phase is distilled under reduced pressure by a rotary evaporator to obtain a hydroxyrubiadin e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap