Internal circulation type thermal power generation system

An internal circulation and generator technology, applied in steam generation, machine/engine, liquid variable capacity machinery, etc., can solve the problems of lack of oxygen, low fuel combustion efficiency, and long time required for the temperature of the combustion furnace, so as to reduce costs, The effect of increasing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art under the premise of not making creative work all belong to the scope of protection of the present invention:

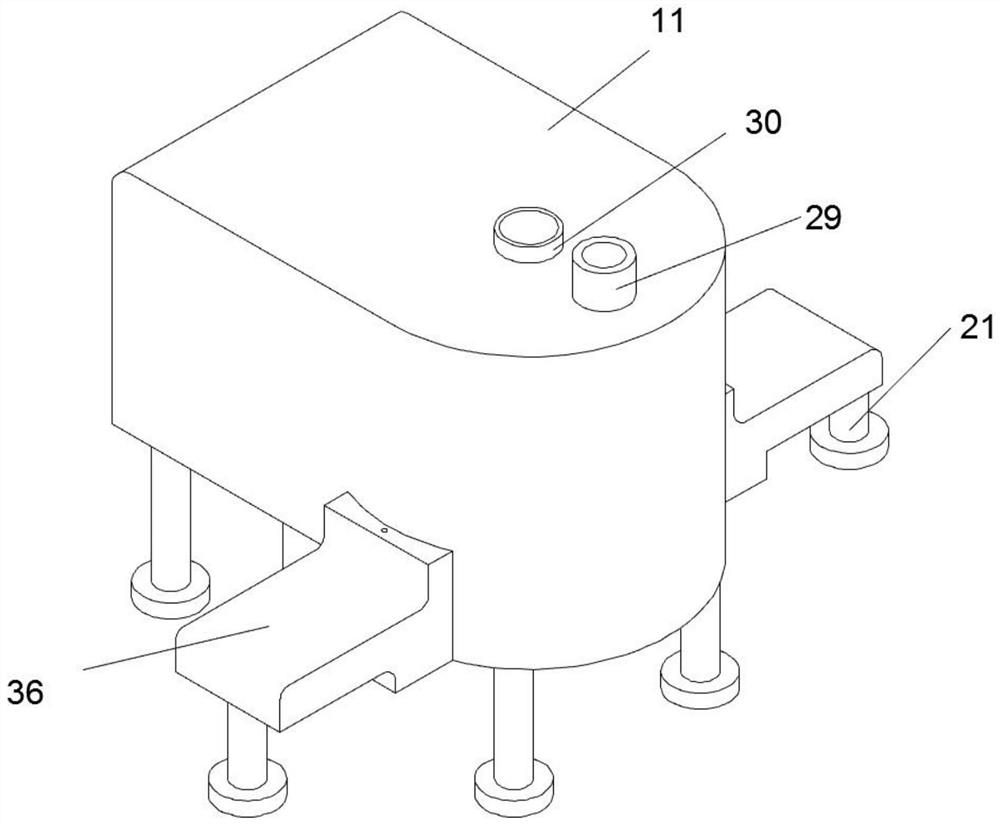

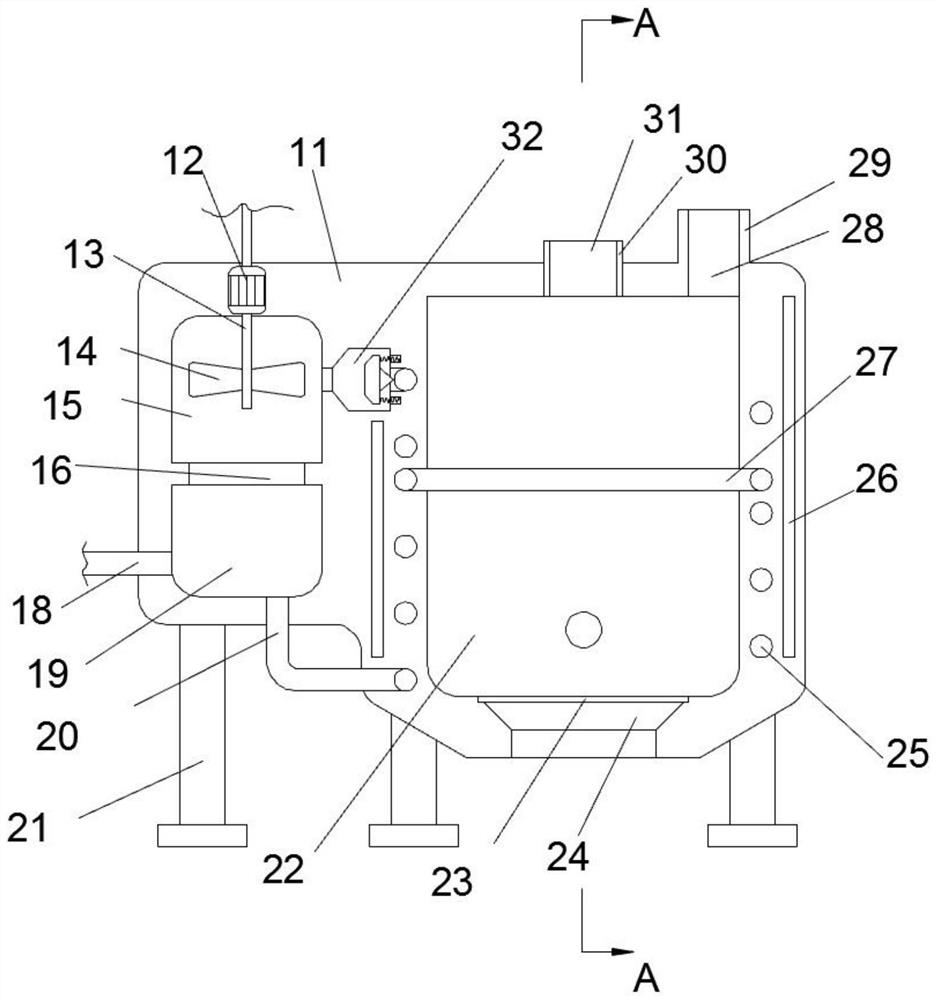

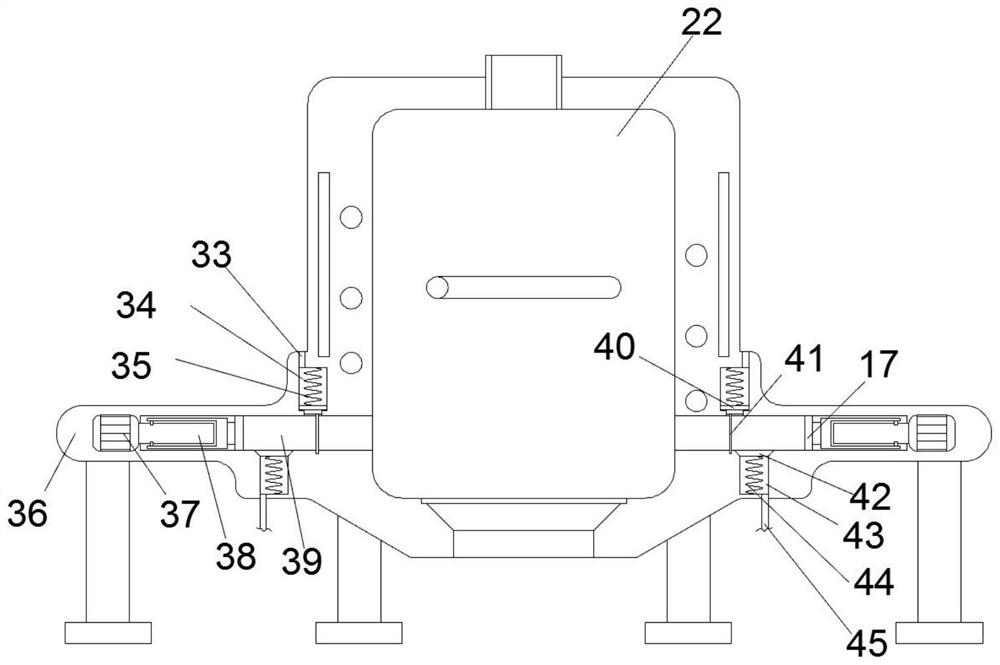

[0028] Refer to the attached Figure 1-Figure 8 , according to an embodiment of the present invention, an internal circulation type thermal power generation system includes a body 11, a feed box 30 is fixed on the upper end surface of the body 11, and a smoke exhaust box 29 is fixed on the right side of the feed box 30 , the body 11 is provided with a power generation chamber 15, the right side of the power generatio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap