Experimental system for measuring friction loss of high-pressure fluid in rotor-static gap and working method of experimental system

A fluid friction and experimental system technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of difficult fluid friction loss and bearing friction loss, reduce the prediction accuracy of friction loss model, and reduce the technical difficulty of shaft end sealing. , to achieve the effect of easy operation, eliminating errors and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with the accompanying drawings and embodiments, and its content is to explain rather than limit the present invention:

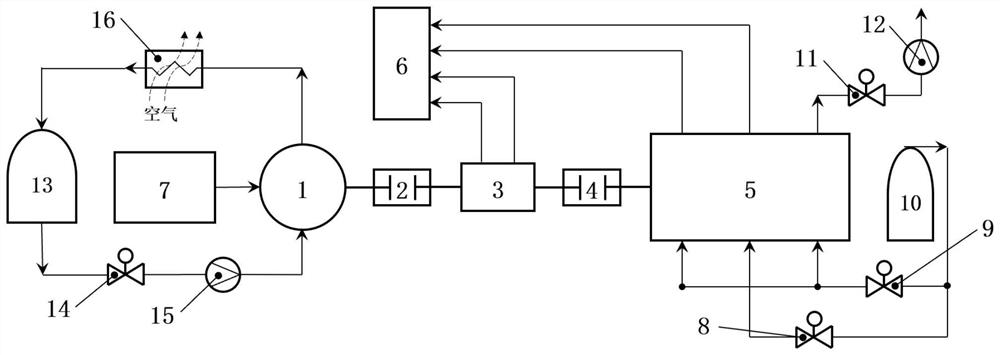

[0040] like figure 1 , is the experimental system for measuring the friction loss of high-pressure fluid in the rotating and static gap of the present invention, including a high-speed motor 1, a torque detection device 3, a main device of the test bench 5, a data acquisition system 6, a gap and a sealed air supply system and a vacuum system;

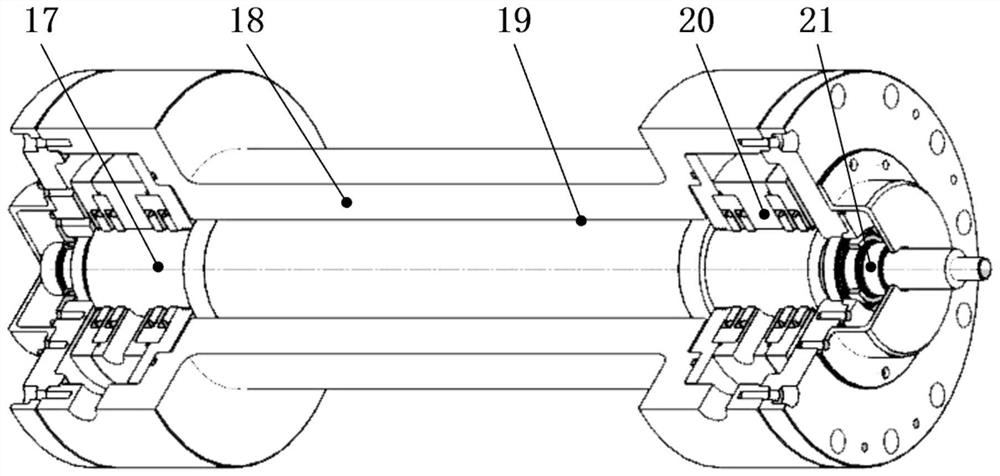

[0041]The main device 5 of the test bench includes a rotor 17 and a casing 18. The rotor 17 is arranged inside the casing 18. Both ends of the rotor 17 are supported by bearings 21. A graphite ring sealing device 20 is provided between the middle of the rotor 17 and the bearings 21 at both ends. A sealing air supply port is provided in the middle of the graphite ring sealing device 20; a rotating and static gap 19 is formed between the middl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap