Assembling mechanism for engine wheel spindle of airplane

A technology for assembling mechanisms and wheels, applied in the directions of axles, wheels, wheels, etc., can solve the problem of inability to effectively find the structural defects of the tight plug, avoid the wheel holding the axle or the tire burst, prevent reverse installation, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

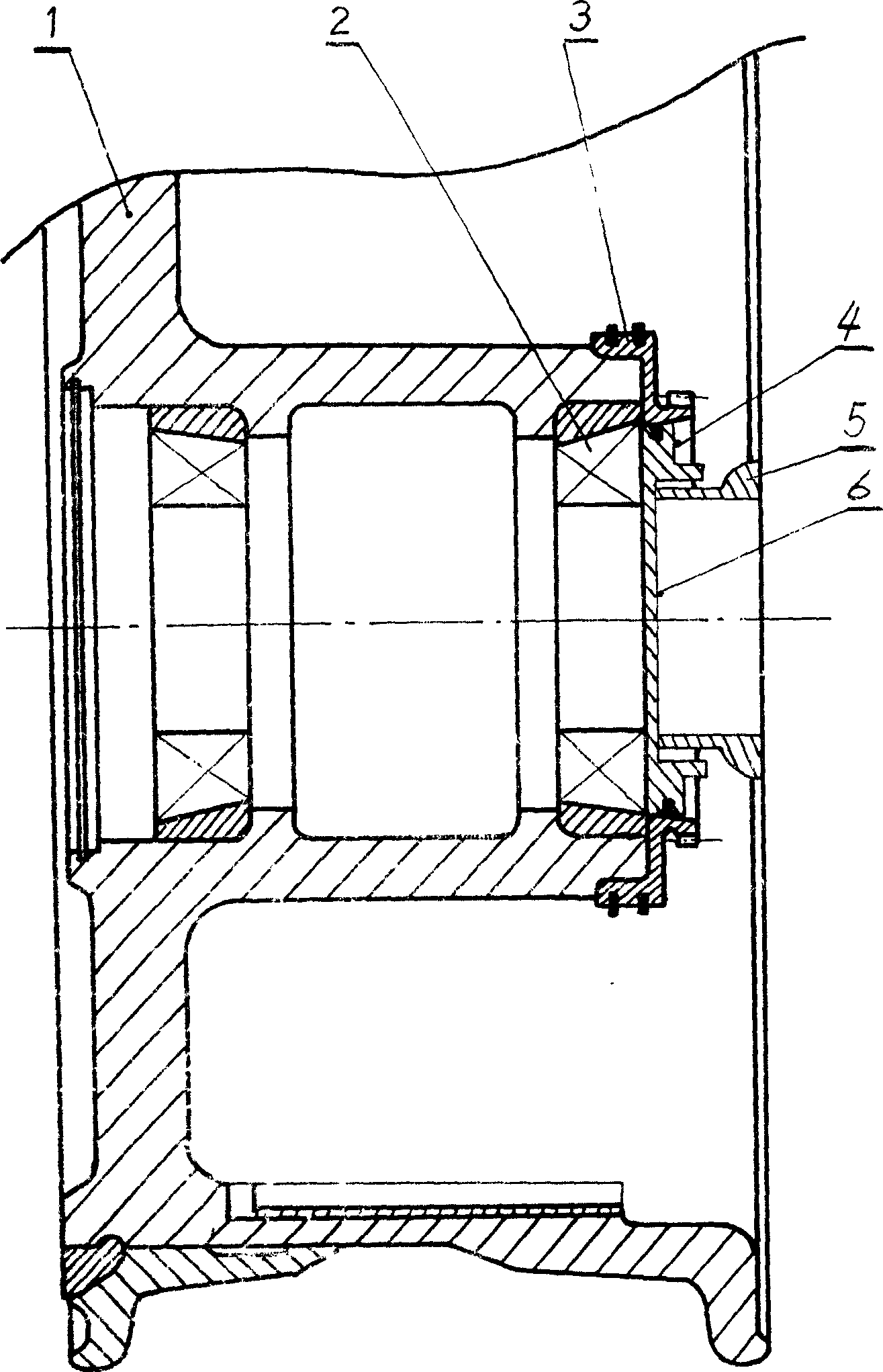

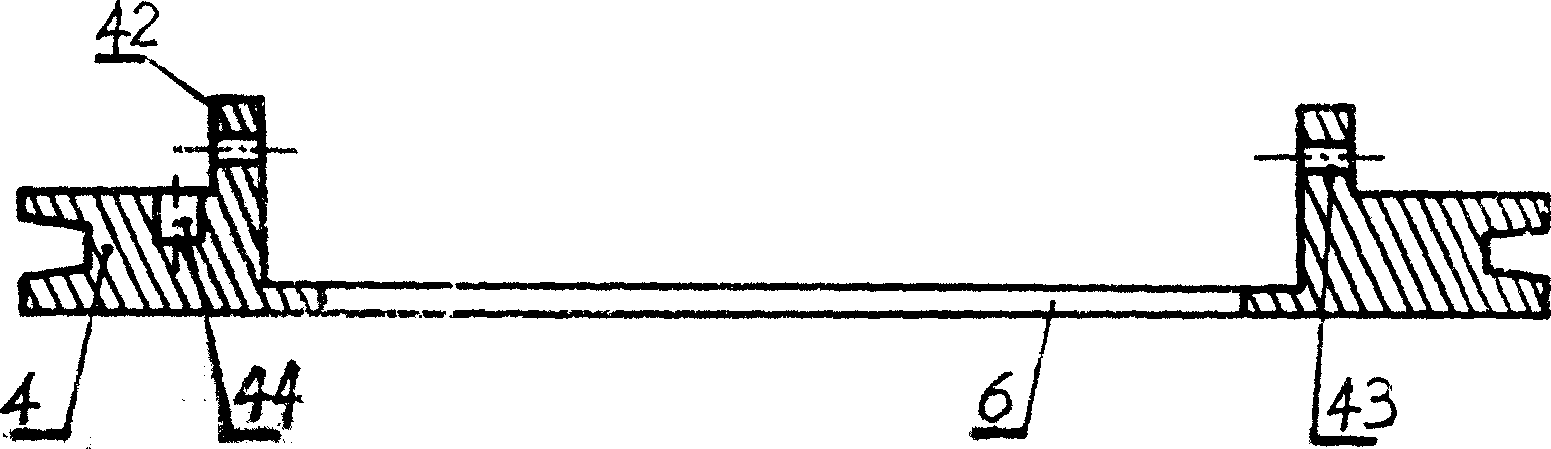

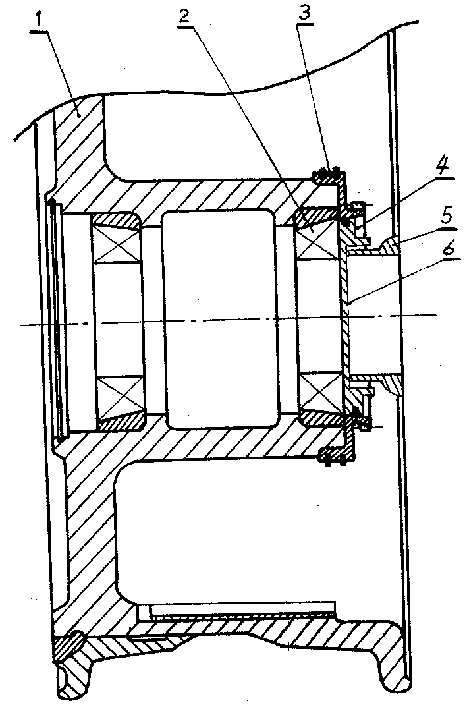

[0008] The assembly structure of the aircraft wheel and its axle is a more critical part of the aircraft landing mechanism. The inner end bushing 7 of the aircraft wheel hub 1 is provided with a conical bearing 2 to make the wheel shaft cooperate with the hub 1 bearing. The brake main body fixing disc, connecting flange, bushing 5 and tightening tool 6 set on the wheel shaft, wherein the tightening tool 6 is a ring-shaped fitting, and a ring sleeve 4 is provided on one side of the ring-shaped bottom plate. The cylindrical surface of the ring sleeve 4 is provided with an annular sealing ring. During normal installation, the bottom plate of the plugging device 6 is tightly pressed on the large end surface of the conical bearing 2, and the bushing 5 is set in the inner cavity of the ring sleeve 4 of the plugging device 6, and then other components are sequentially connected and installed. The plugging device 6 The ring sleeve 4 upper surface is provided with an annular boss 42, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap