Flame igniter for igniting condensed fire detonator under condition of high pressure

A high-pressure environment, fire and explosive technology, applied in the field of igniters, can solve problems such as unreliable ignition methods, and achieve the effect of simple structure, convenient operation, accurate and reliable ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

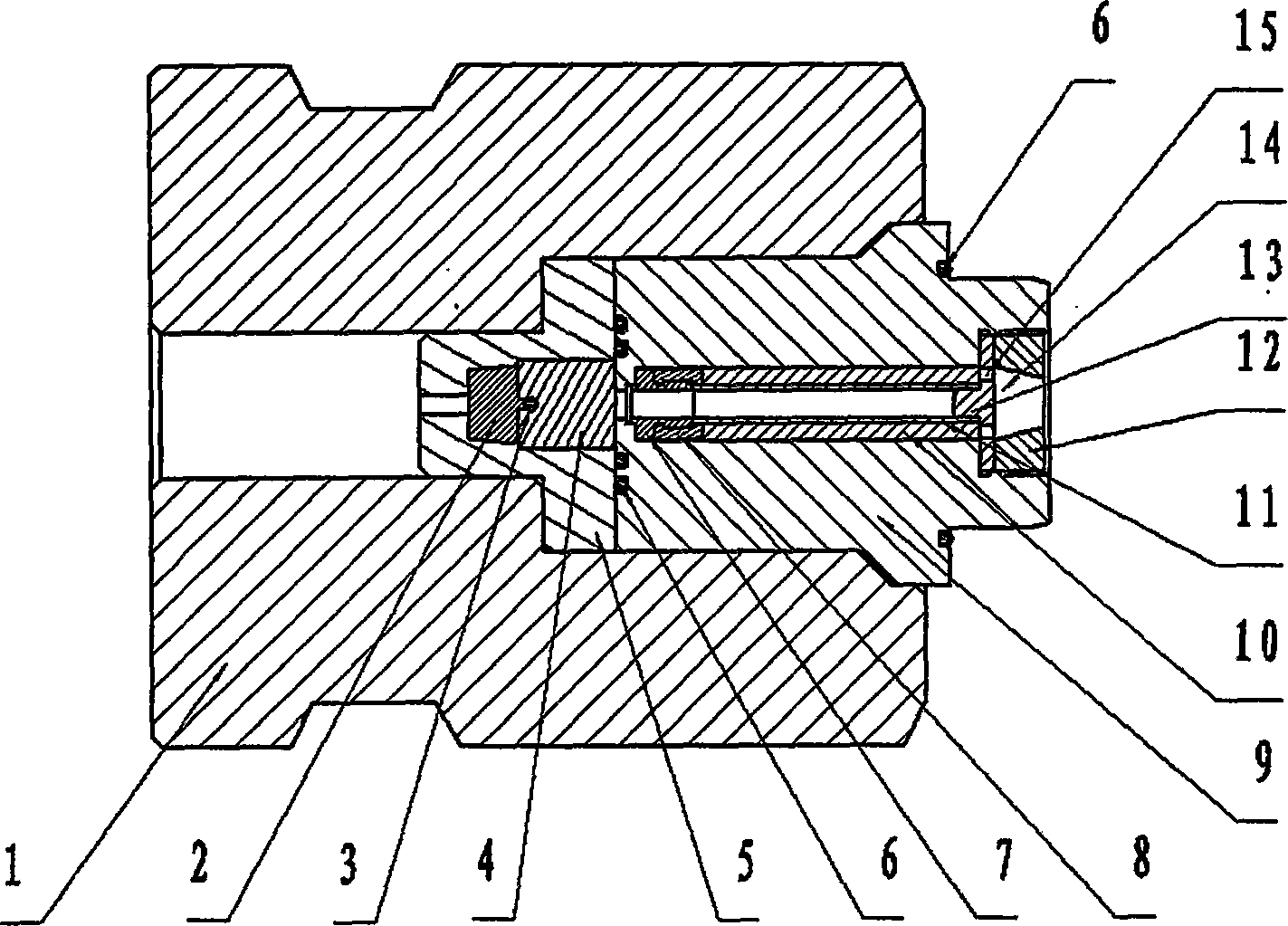

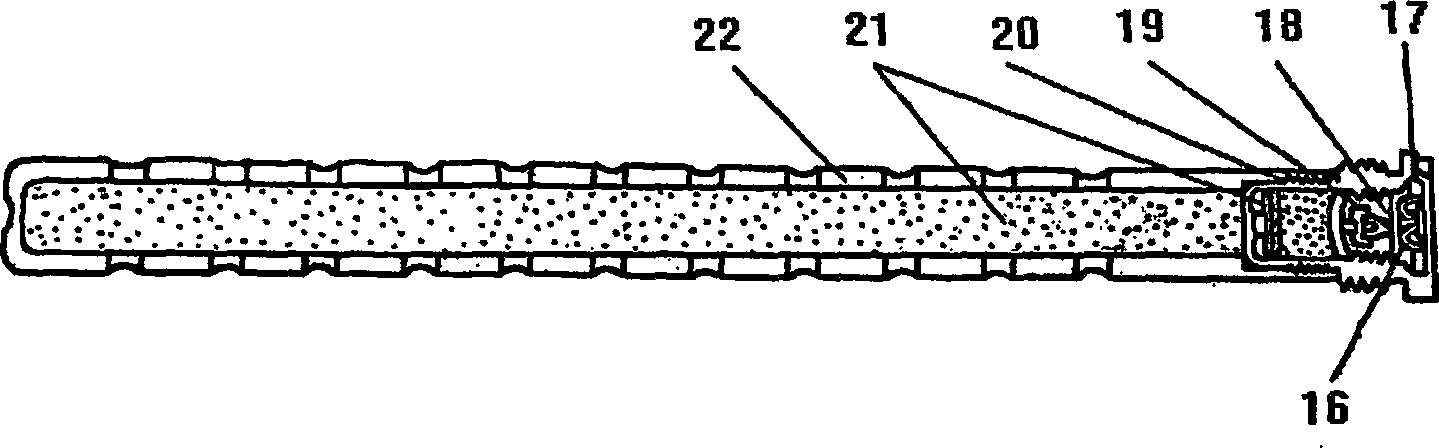

[0017] Select a thick-walled fire transmission tool seat 9 with a stepped circular hole on the center line. One end of the fire transmission tool seat has an internal thread. Select a metal pipe with good heat conduction as the fire transmission tube 11, and one end of the fire transmission tube is connected with the fire transmission tube base 7, the fire transmission tube fastening screw 8, and the other end is connected with the fire transmission tool plug 13. Select a fire transmission tube head 12, the circumference has external threads, and the center has a conical hole as the fire hole 16. With the fire transmission tube head 12, the fire transmission tube 11, the fire transmission tube base 7, the fire transmission tube fastening screw 8 and the fire transmission tool plug 13 are connected together with the fire transmission tool seat 9 t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap