Prepn of powdered briquette adhesive

A binder and briquette technology, which is applied in the field of preparation of dry powder briquette binders, can solve problems such as difficulty in improving production efficiency, slow melting speed of dry powder binders, and affecting briquette production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

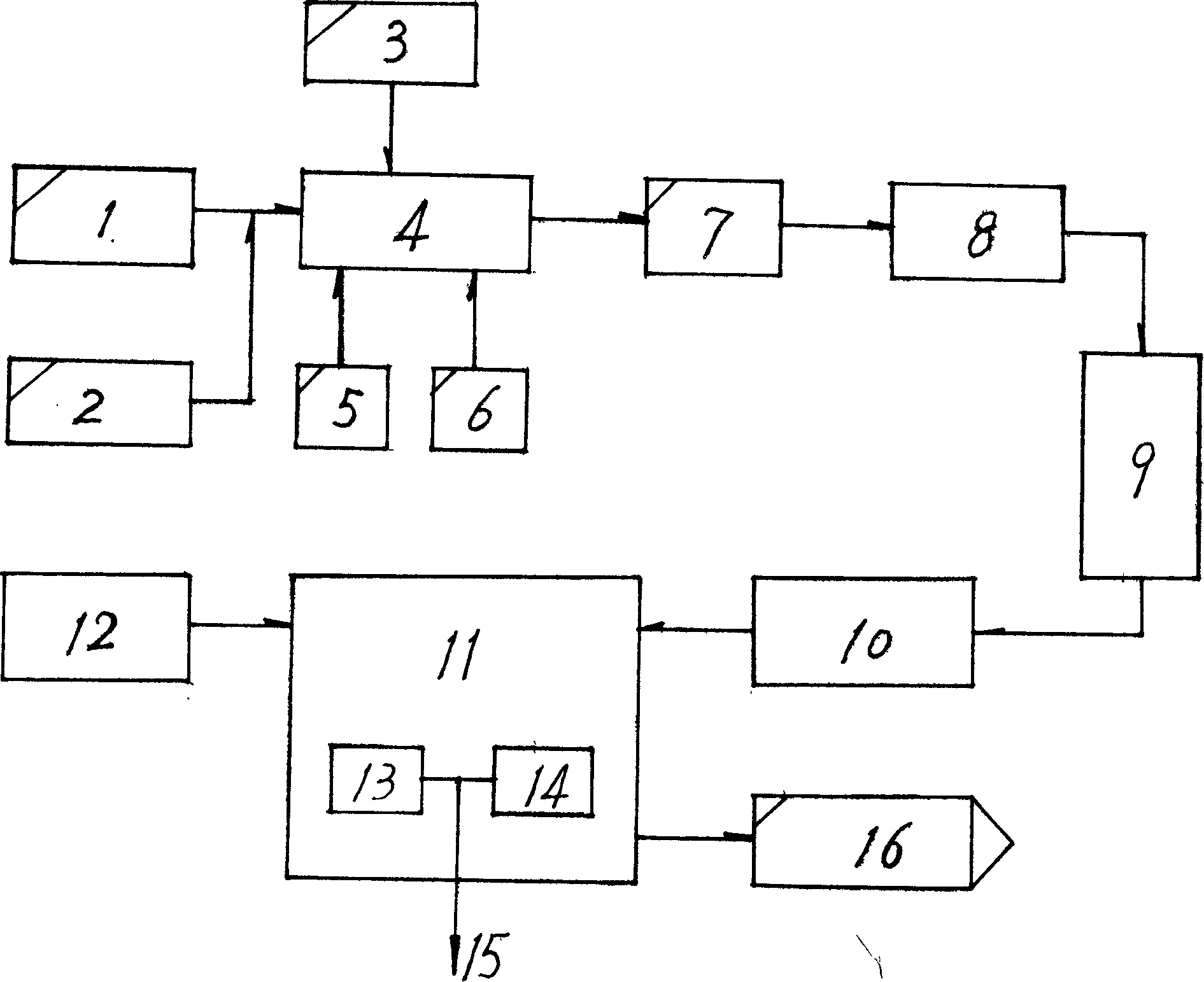

[0008] The present invention will be further described below in conjunction with embodiment. According to the technical process of the present invention, the 3m 3 Input clean water into the glass-lined reactor 4, heat up to 70-95°C, add 1600kg of humic acid 1 and 220kg of sodium hydroxide 2, and then add a small amount of heat stabilizer 5 and activity accelerator 6. After reacting in the kettle for 60 minutes, the liquid briquette binder 7 with a solid content of 23% and a viscosity of 30 seconds (based on 4 cups) of 5000 kg was obtained. After the centrifugal filtration process 8 is stored in the storage tank 9, the spray drying system is started, and the hot air with a temperature of 300° C. is blown in through the hot air generator 12, and the centrifugal turntable of the spray drying tower 11 is started simultaneously to send the liquid briquette binder 7 to the storage tank 9. Into the centrifugal turntable at the top of the spray drying tower 11, the feed liquid is spraye

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap