Connecting structure of refrigerant suction pipe for multi-cylinder rotary compressor

A technology of rotary compressor and connection structure, applied to rotary piston type/oscillating piston type pump components, rotary piston type/oscillating piston type pump combination for elastic fluid, components of pumping device for elastic fluid, etc. Direction, can solve problems such as noise, product without structure, inconvenience, etc., to achieve the effect of reducing volume, simplifying composition, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the connection structure of the refrigerant suction pipe of the multi-cylinder rotary compressor proposed according to the present invention is described below in conjunction with the accompanying drawings and preferred embodiments. Specific embodiments, structures, features and effects thereof are described in detail below.

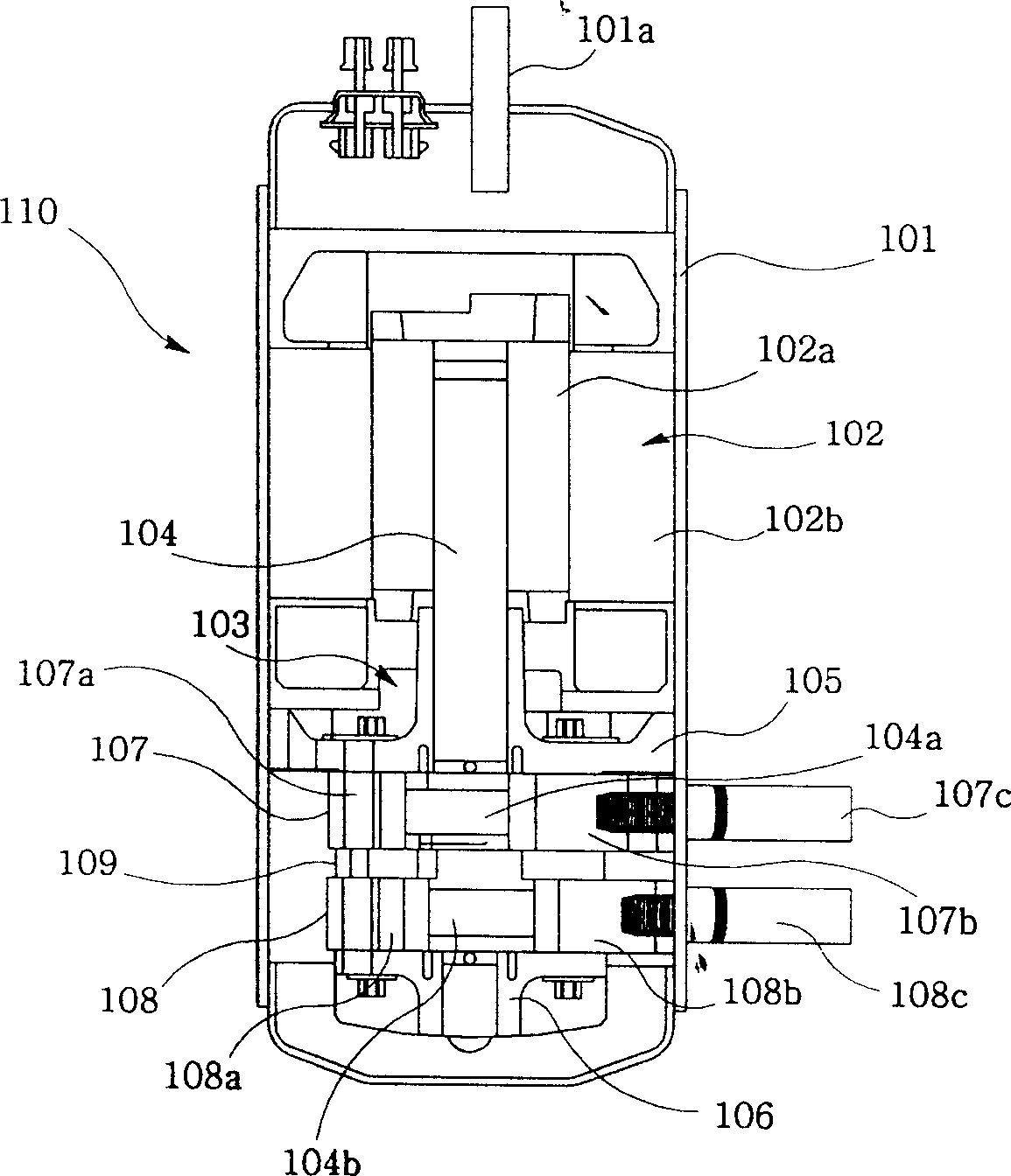

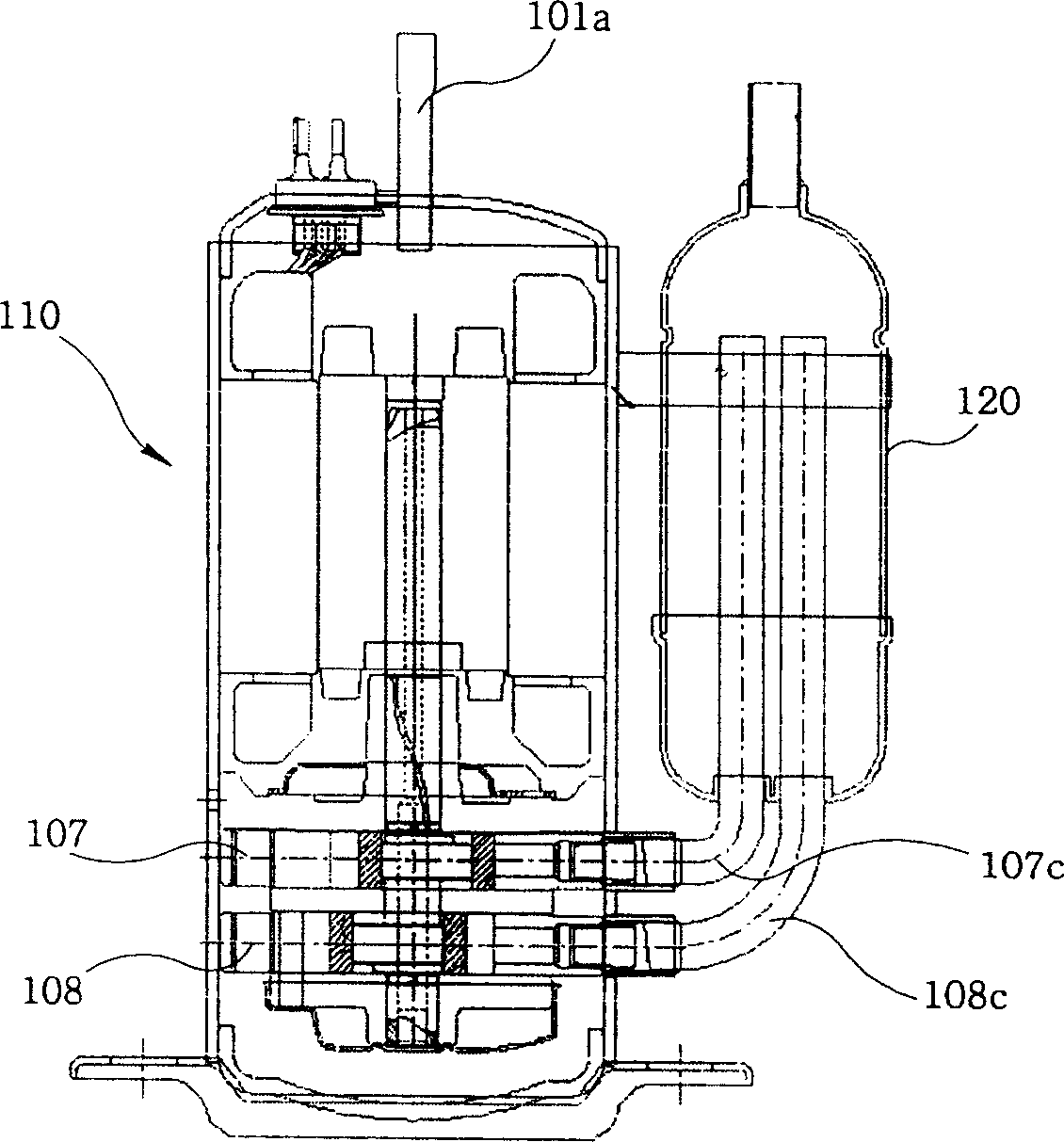

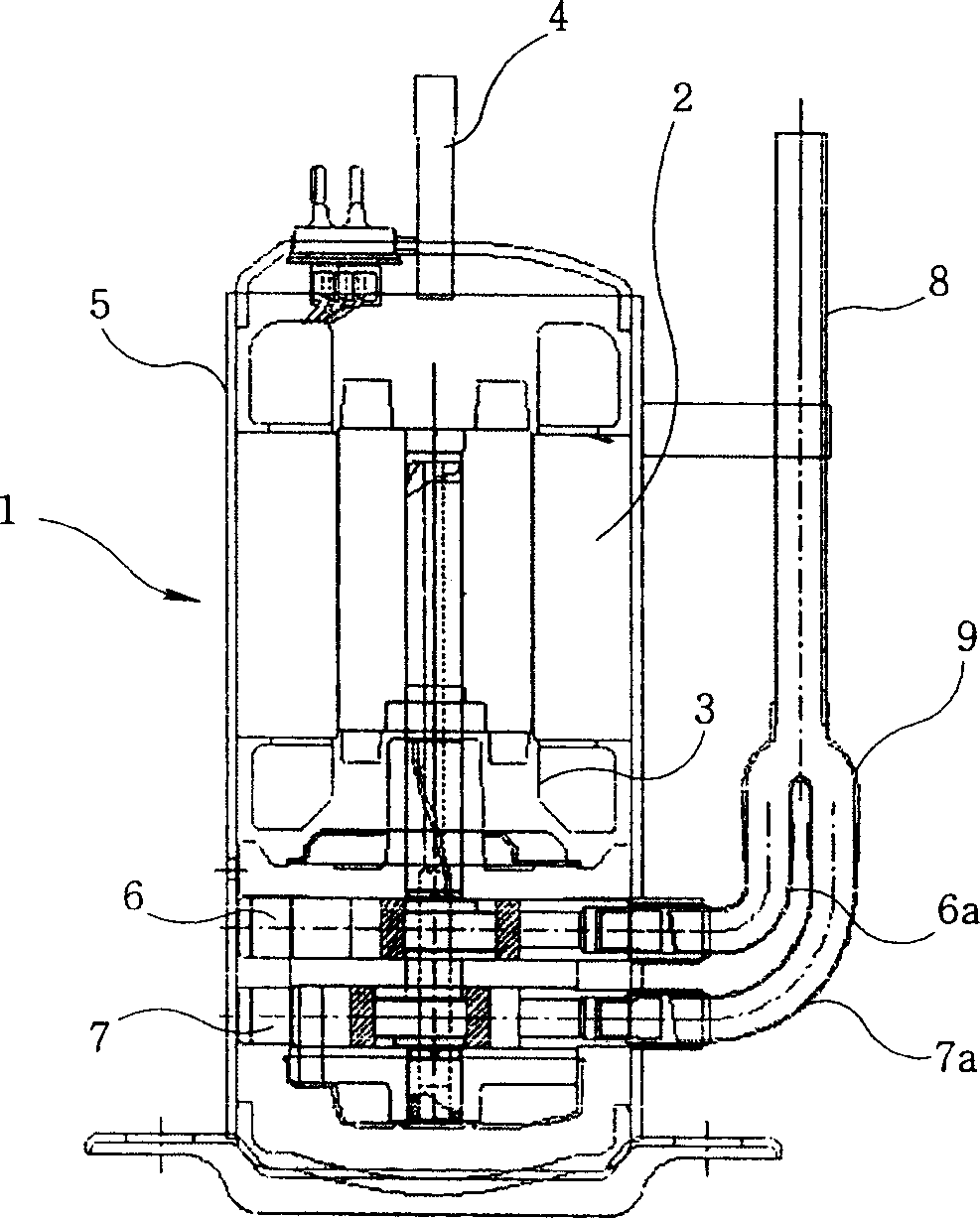

[0051] image 3 is a longitudinal sectional view of the refrigerant suction pipe connection structure of the multi-cylinder rotary compressor according to the present invention, Figure 4 is a longitudinal sectional view according to another embodiment of the present invention, Figure 5 It is a cross-sectional view illustrating a motor connected to a multi-cylinder rotary compressor according to the present invention. The multi-cylinder rotary compressor 1 is composed of the following components; a motor part formin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap