Method for simply detecting CZ state 2A12 aluminum alloy over burning

A detection method, aluminum alloy technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of safety and environmental protection, difficult in-service parts or finished product detection, complicated sample preparation, etc., to avoid major quality accidents, Improved work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

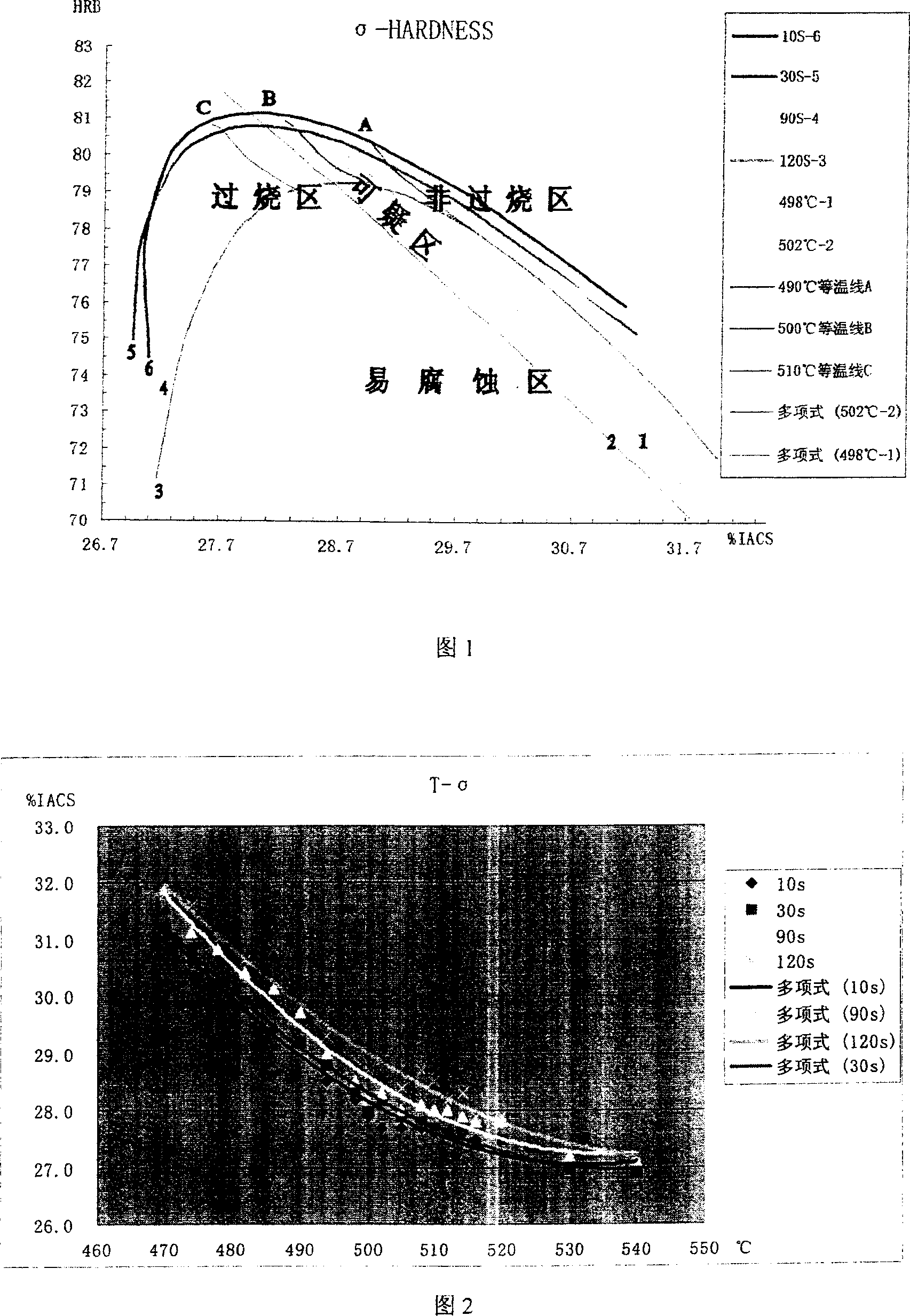

[0028] As shown in Figure 1, the judgment diagram is a judgment diagram for overburned areas, non-overburned areas, suspicious areas, and corrosion-prone areas. According to the existing research results, it is known that the 2Al2 aluminum alloy is overburned at 500 °C. Considering the experimental error, it is determined that the area below 498°C is definitely not overheating, that is, the right side of Line 1; the area above 502°C is definitely overburning, that is, the left side of Line 2; the area between 498°C and 502°C is a suspicious area, It needs to be further tested by metallographic method, that is, the area between lines 1 and 2.

[0029] The abscissa in the figure represents the conductivity value, and the ordinate represents the hardness value; lines 3, 4, 5, and 6 represent the change curves of different cooling times (from 10 seconds to 120 seconds). Isotherms can be made by connecting the same temperatures in each line (such as lines A, B, and C). As long as th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap