Method for preparing substituted imidazolyl carboxyamides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

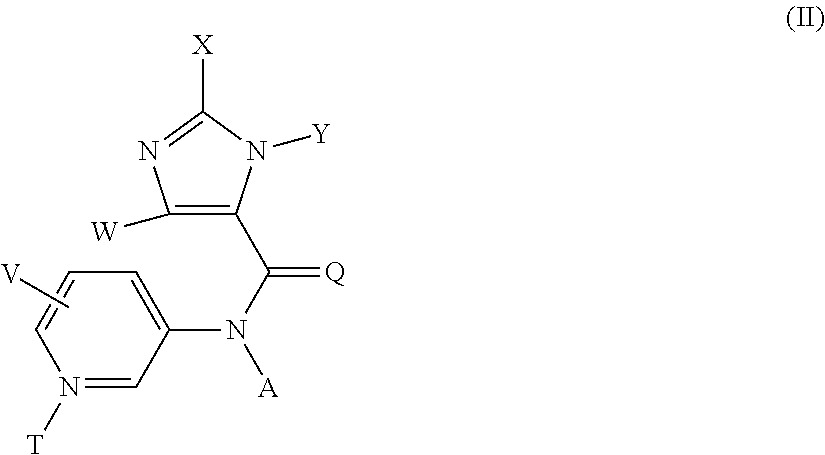

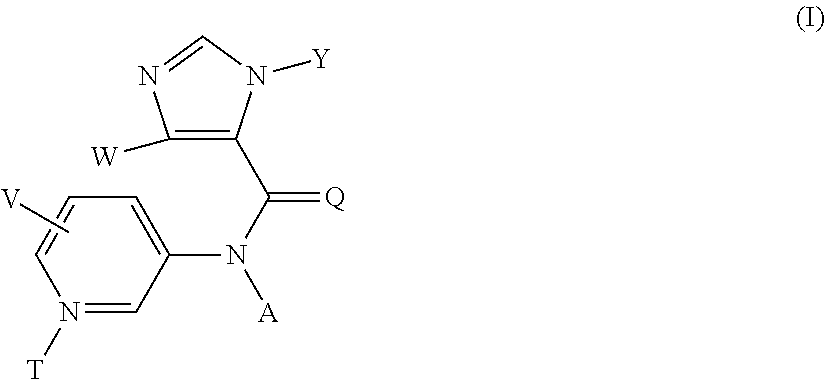

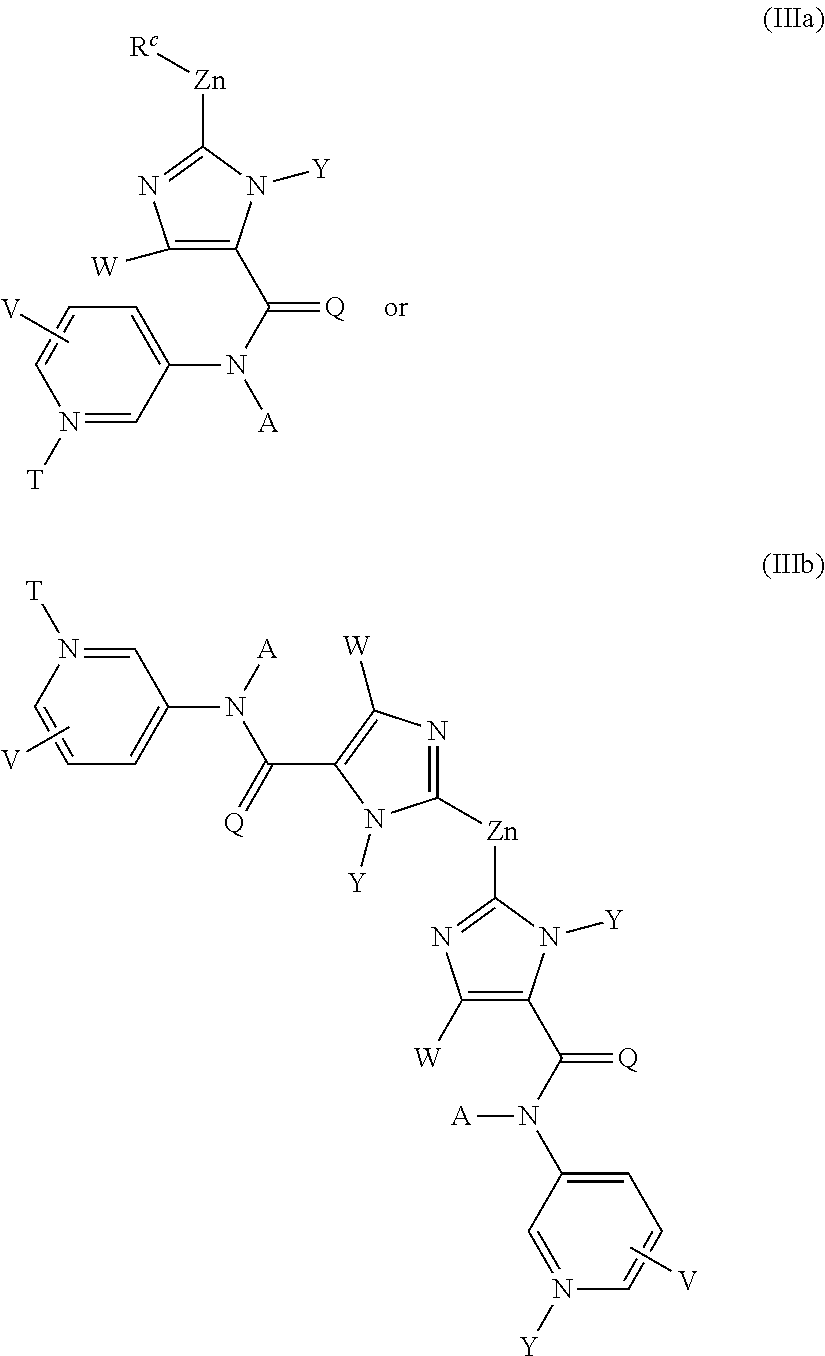

Method used

Image

Examples

example 1

[0261]

Synthesis of 2-iodo-N,1-dimethyl-N-(pyridin-3-yl)-1H-imidazole-5-carboxamide

[0262]To N,1-dimethyl-N-(pyridin-3-yl)-1H-imidazole-5-carboxamide (216 mg, 1.0 mmol), dissolved in THF (2 ml), was added TMPZnCl.LiCl (1.31M in THF, 0.84 ml, 1.1 mmol) at 25° C. under argon; this reaction solution was stirred for 30 minutes. Subsequently, iodine (355 mg) in THF (4 ml) is added at 25° C. and the solution is stirred for a further 30 min. After customary workup by addition of saturated ammonium chloride and sodium thiosulfate solutions, the reaction mixture is extracted with ethyl acetate, and the combined organic phases are dried over Na2SO4 and concentrated in a membrane pump vacuum. After purification by column chromatography (ethyl acetate / cyclohexane), 2-iodo-N, 1-dimethyl-N-(pyridin-3-yl)-1H-imidazole-5-carboxamide (262 mg, 77%) is obtained as a yellow solid.

[0263]MH+: 343.0; 1H-NMR (d6-DMSO): δ 8.48 (m, 2H), 7.83 (m, 1H), 7.44 (m, 1H), 6.27 (s, 1H), 3.73 (s, 3H), 3.37 (s, 3H).

example 2

[0264]

Synthesis of N,1-dimethyl-N-(pyridin-3-yl)-2-[3-(trifluoromethyl)phenyl]-1H-imidazole-5-carboxamide

[0265]To N,1-dimethyl-N-(pyridin-3-yl)-1H-imidazole-5-carboxamide (216 mg, 1.0 mmol), dissolved in THF (2 ml), was added TMPZnCl.LiCl (1.31M in THF, 0.84 ml, 1.1 mmol) at 25° C. under argon; this reaction solution was stirred for 30 minutes. Subsequently, 1-iodo-3-(trifluoromethyl)benzene (544 mg, 2 mmol) in THF (3 ml) and tetrakis(triphenylphosphine)palladium(0) (115 mg, 0.1 mmol) were added at 25° C. and the solution was stirred at 80° C. for a further 1 hour. After customary workup by addition of saturated ammonium chloride solution, the reaction mixture was extracted with ethyl acetate, and the combined organic phases were dried over Na2SO4 and concentrated in a membrane pump vacuum. After purification by column chromatography (ethyl acetate / cyclohexane), N,1-dimethyl-N-(pyridin-3-yl)-2-[3-(trifluoromethyl)phenyl]-1H-imidazole-5-carboxamide (212 mg, 59%) was obtained as a whit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap