Feed device for feeding molten metal in to a crystallizer

a technology of crystallizer and discharge device, which is applied in the direction of molten metal supplying equipment, molten metal conveying equipment, molten metal pouring equipment, etc., can solve the problems of the discharge device of the known art, the very carrying out of the process can be jeopardized, and the continuous casting of metal strips using counter-rotating rolls, etc., to reduce the kinetic energy of liquid steel pouring and the shape of the feed device is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

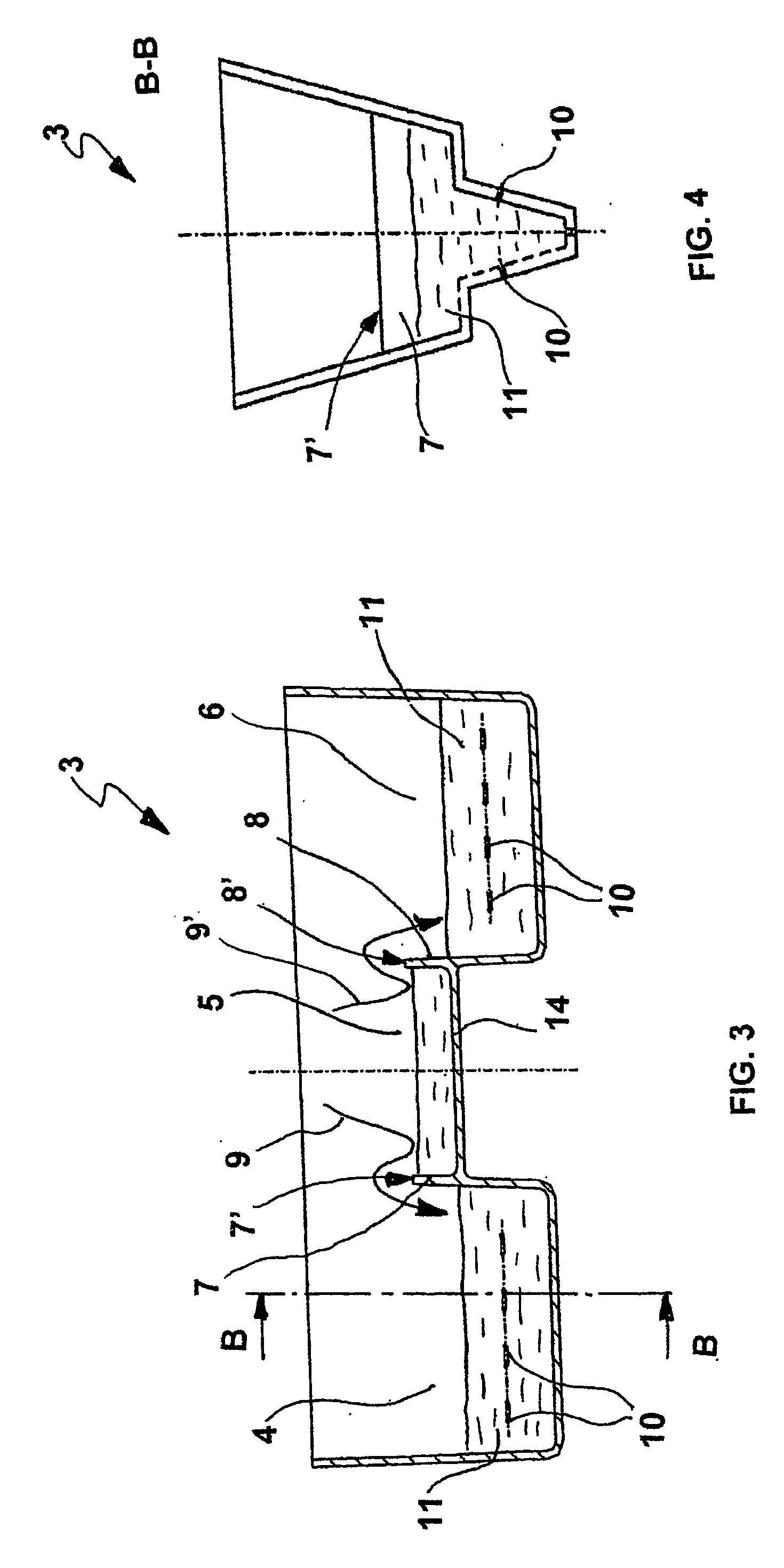

[0017] With reference to the figures, described herein is an embodiment of a feed device for feeding molten metal, in particular liquid steel, into an ingot mould for a continuous-casting machine with two crystallizer rolls. In particular, FIG. 1 shows a cross section according to a vertical plane parallel to the axis of the crystallizer rolls of parts of a continuous-casting machine, designated, as a whole, by the reference number 1, comprising the feed device according to the invention. In the remainder of the description, reference will be made to steel, but it is understood that the device can be adapted to the discharge of other metals for which the same casting technique is used.

[0018] The molten steel coming from a tundish, not represented in the figures, is poured, through a discharger 2, into a first distributor 3. The discharger 2 is substantially shaped like a funnel turned upside-down with the divergent section set downwards in the direction of the distributor 3, and has a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap