Anisotropically conductive connector, production process thereof and application product thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

EXAMPLE 1

[0203] A frame plate, a mold for molding elastic anisotropically conductive films and a spacer for molding were produced in accordance with the following respective conditions.

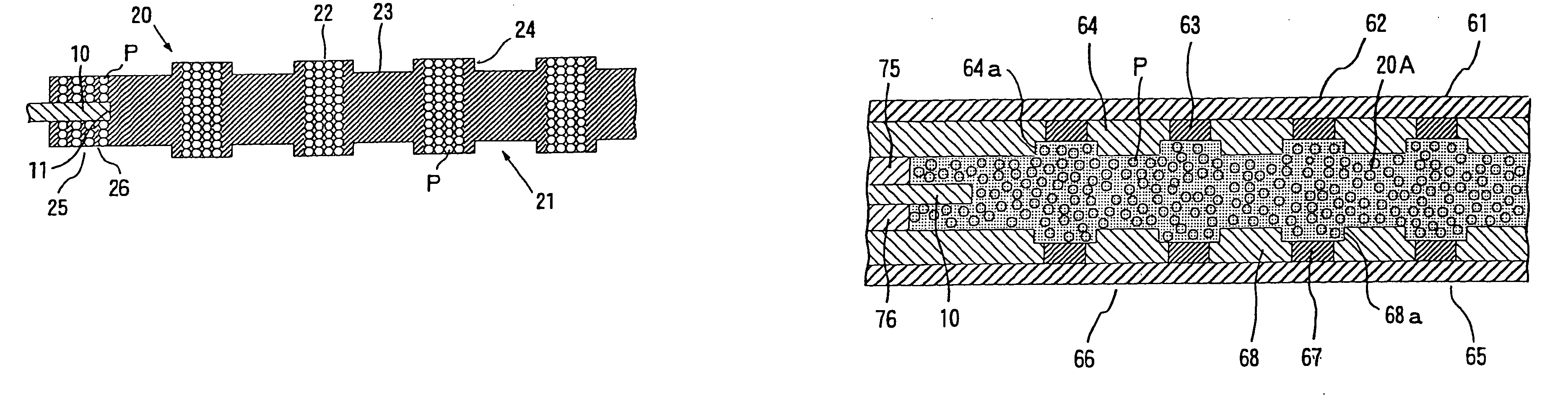

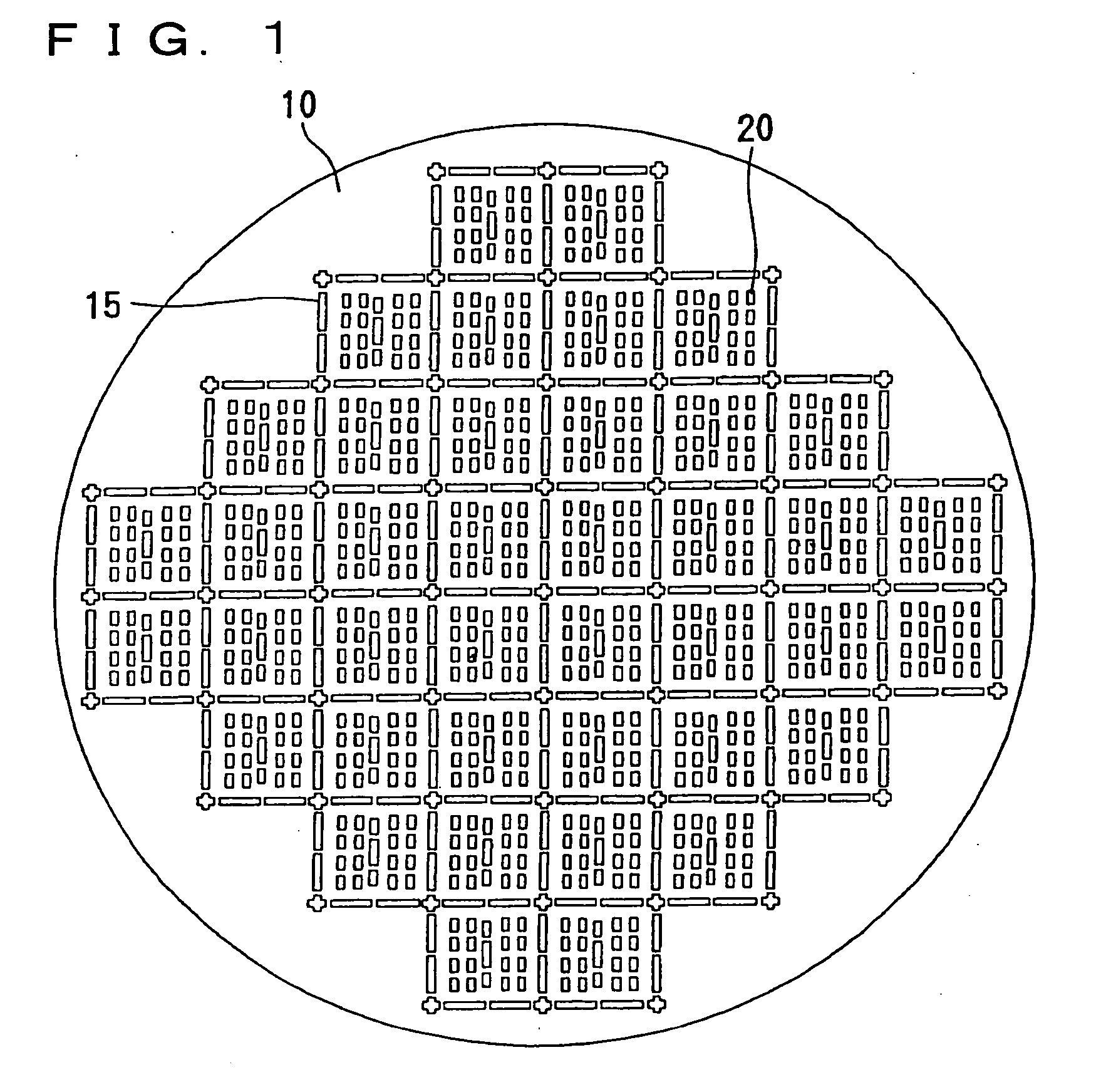

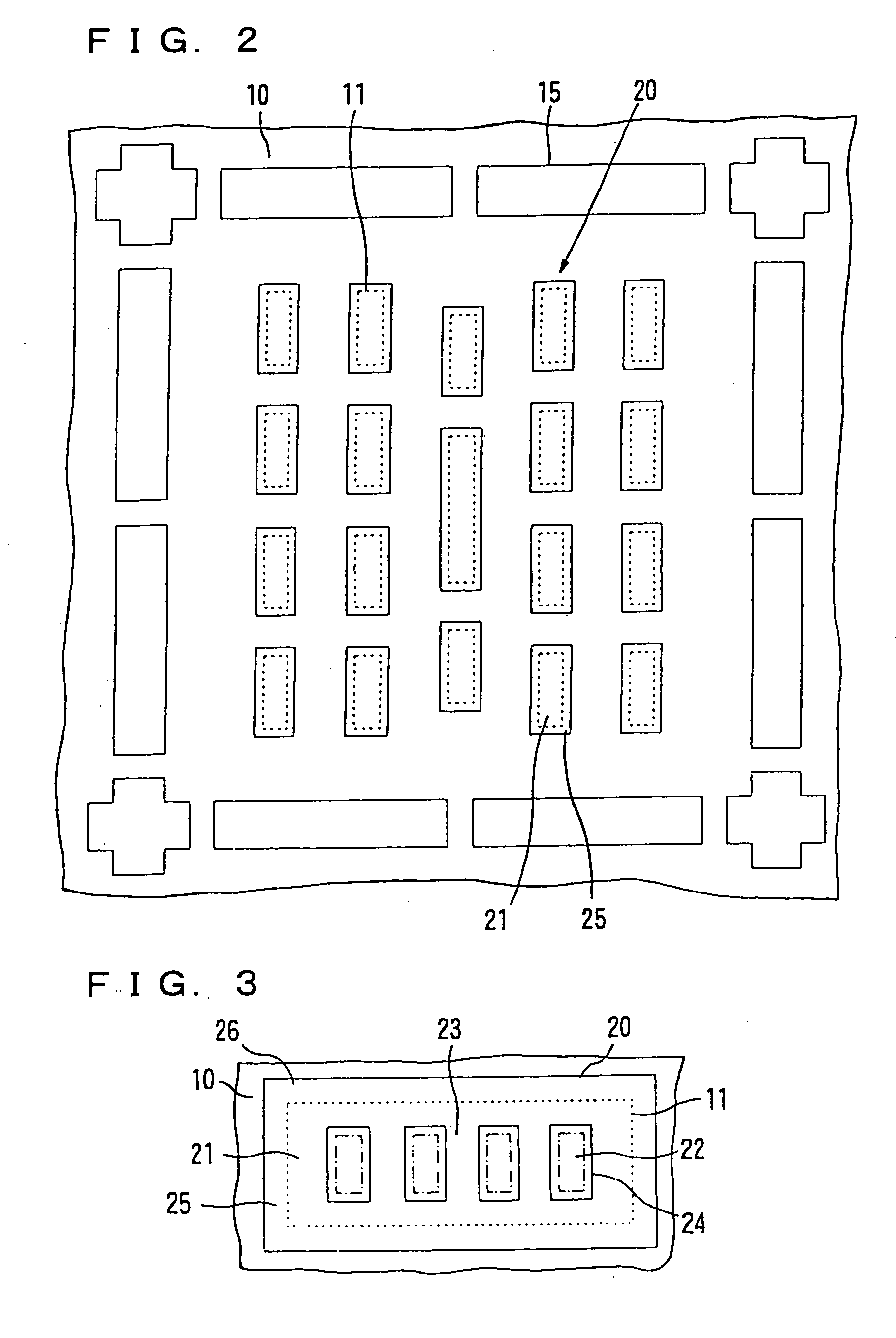

[Frame plate (10)]

Material:

[0204] Covar (saturation magnetization: 1.4 Wb / m2), thickness: 0.4 mm, size of through-hole (11): 16 mm×16 mm (sectional area S1 in the plane direction: 2.56 cm2)

[Mold (60)]

Base plates (62, 66):

[0205] Material: iron, thickness: 6 mm;

Ferromagnetic substance layers (63, 67):

[0206] Material: nickel, size: diameter: 1 mm (circular form), thickness: 0.1 mm, arrangement pitch (center distance): 2 mm, number of ferromagnetic layers: 64 layers (8×8 layers);

Non-magnetic substance layers (64, 68):

[0207] Material: that obtained by subjecting a dry film resist to a curing treatment, size of recesses (64a, 68a): diameter: 1.1 mm (circular form), depth: 0.4 mm, thickness of other portions than the recess: 0.5 mm (thickness of the recess: 0.1 mm).

[Spacers (75, 76) for moldi

Example

EXAMPLES 2 to 4

[0215] Respective anisotropically conductive connectors were produced in the same manner as in Example 1 except that frame plates (10), molds (60) and spacers (75, 76) for molding were produced in accordance with their corresponding conditions shown in Table 1, and these frame plates (10), molds (60) and spacers (75, 76) for molding were used to form each elastic anisotropically conductive film (20). The total volume of the conductive particles in the molding material layer, the size of the elastic anisotropically conductive film (20), and the like are shown in Table 2.

[0216] The proportions of the conductive particles contained in the conductive parts (22) for connection and the part (25) to be supported in the elastic anisotropically conductive film (20) of each of the anisotropically conductive connectors thus obtained were investigated. As a result, the contents were 35% in terms of a volume fraction for the conductive parts (22) for connection and 10% for the part

Example

COMPARATIVE EXAMPLES 1 to 4

[0219] Respective anisotropically conductive connectors were produced in the same manner as in Examples 1 to 4 except that the material of the frame plate (10) was changed to SUS304 (saturation magnetization: 0.01 Wb / m2).

[0220] The parts (25) to be supported in the elastic anisotropically conductive films (20) of the anisotropically conductive connectors thus obtained were observed. As a result, it was confirmed that the conductive particles were scarcely present in all the parts (25) to be supported.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap