Process and composition for making olanzapine form i

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

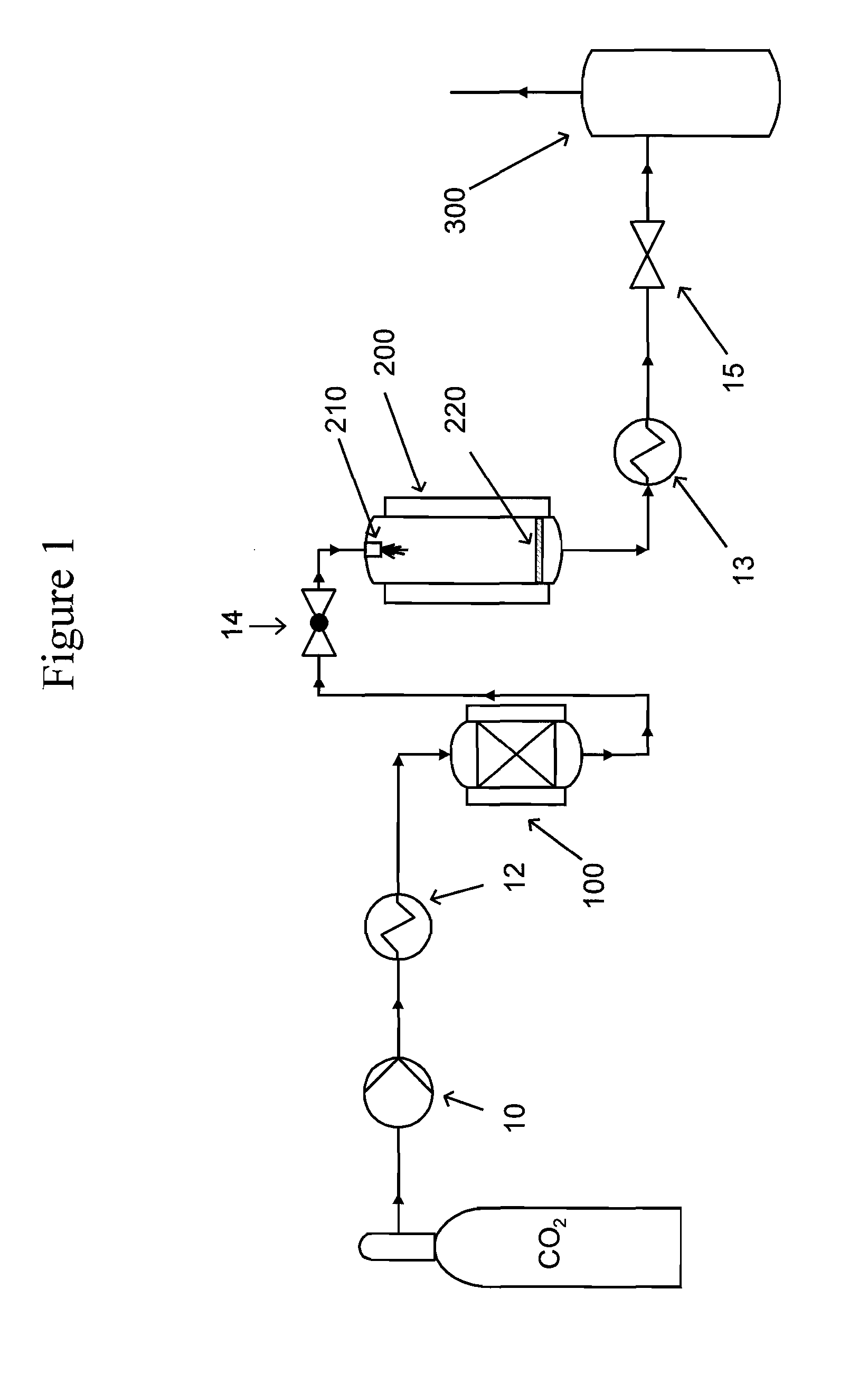

[0036] Using an equipment scheme similar to that depicted in FIG. 1, a 500 ml extractor is filled to about half its volume with powdered olanzapine containing glass wool. The temperature of the pre-heater, the extractor, and autoclave are set to 40° C. and the pressure is built up with carbon dioxide (13.5 kg / hour) and maintained constant at 300 bars in the extractor and 20 bars in the autoclave. The ball valve before the autoclave is opened allowing the supercritical carbon dioxide containing olanzapine picked-up in the extractor to pass through the expansion nozzle, having a 200 micron diameter, and expand / decompress in the 6 liter autoclave. Olanzapine precipitates. The depressurized carbon dioxide fluid is allowed to leave the autoclave through the filter to the flash vessel via the post heater. The process is stopped by turning off the carbon dioxide supply and closing the ball valve before the autoclave. The heated autoclave is slowly depressurized and the product collected o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap