Industrial Process for Production of an Aromatic Carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1

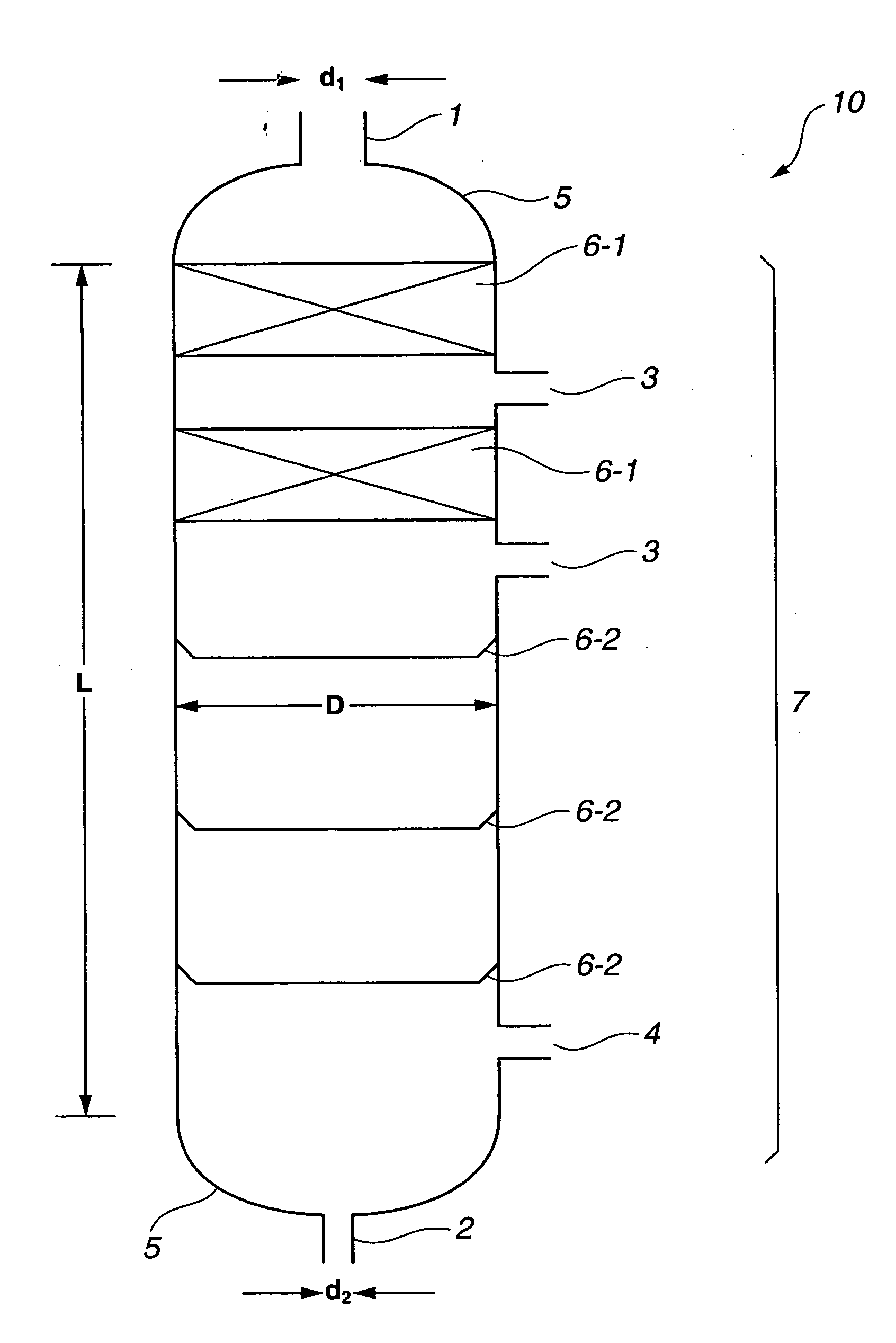

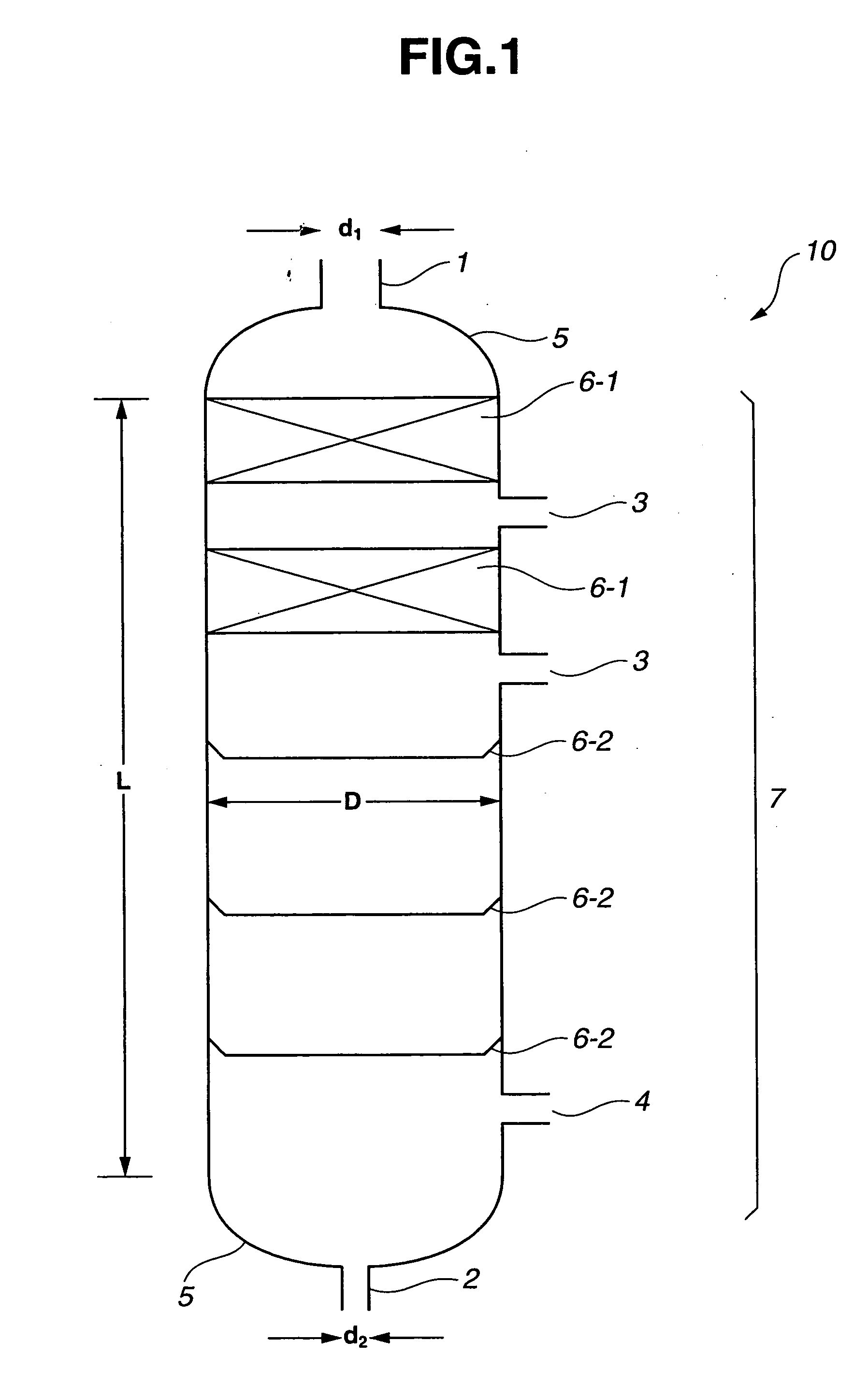

[0134] A continuous multi-stage distillation column as shown in FIG. 1 having L=3100 cm, D=500 cm, L / D=6.2, n=30, D / d1=3.85, and D / d2=11.1 was used. In this example, as the internal, two sets of Mellapak (total theoretical number of stages 11) were installed in the upper portion, and the sieve tray having the cross-sectional area per hole of approximately 1.3 cm2 and a number of holes of approximately 250 / m2 was used in the lower portion.

[0135] A mixture containing 18% by weight of methyl phenyl carbonate that had been obtained by subjecting a mixture containing dimethyl carbonate and phenol in a weight ratio of dimethyl carbonate / phenol=1.3 to a transesterification reaction was used as a starting material. This starting material contained 26% by weight of dimethyl carbonate, 6% by weight of anisole, 48% by weight of phenol, and 1% by weight of diphenyl carbonate, and further contained approximately 100 ppm of Pb(OPh)2 as a catalyst. The starting material substanti

Example

Example 2

[0138] Reactive distillation was carried out under the following conditions using the same continuous multi-stage distillation column as in Example 1.

[0139] A mixture containing 21% by weight of methyl phenyl carbonate that had been obtained by subjecting a mixture containing dimethyl carbonate and phenol in a weight ratio of dimethyl carbonate / phenol=1.9 to a transesterification reaction was used as a starting material. This starting material contained 32% by weight of dimethyl carbonate, 5% by weight of anisole, 41% by weight of phenol, and 1% by weight of diphenyl carbonate, and further contained approximately 250 ppm of Pb(OPh)2 as a catalyst. The starting material substantially did not contain halogens (outside the detection limit for the ion chromatography, i.e. 1 ppb or less).

[0140] The starting material was introduced into the continuous multi-stage distillation column at a flow rate of 80 ton / hr from a starting material inlet installed between the Mellapak and

Example

Example 3

[0142] Reactive distillation was carried out under the following conditions using the same continuous multi-stage distillation column as in Example 1, except that the cross-sectional area per hole of the sieve tray was made to be approximately 1.8 cm2.

[0143] A mixture containing 16% by weight of methyl phenyl carbonate that had been obtained by subjecting a mixture containing dimethyl carbonate and phenol in a weight ratio of dimethyl carbonate / phenol=1.4 to a transesterification reaction was used as a starting material. This starting material contained 27% by weight of dimethyl carbonate, 7% by weight of anisole, 49% by weight of phenol, and 0.5% by weight of diphenyl carbonate, and further contained approximately 200 ppm of Pb(OPh)2 as a catalyst. The starting material substantially did not contain halogens (outside the detection limit for the ion chromatography, i.e. 1 ppb or less).

[0144] The starting material was introduced into the continuous multi-stage distillation

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap