Cleanser for Slit Coater, Slit Coater for Manufacturing Display Device and Manufacturing Method for Display Device

a technology of slit coater and cleaning solution, which is applied in the direction of detergent compositions, surface-active detergent compositions, chemistry apparatus and processes, etc., can solve the problem that the slit coater cannot be cleaned efficiently, and achieve the effect of efficient cleaning of the slit coater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Hereinafter, exemplary embodiments of the present invention will be described with reference to accompanying drawings, wherein like numerals refer to like elements and repetitive descriptions will be avoided as necessary.

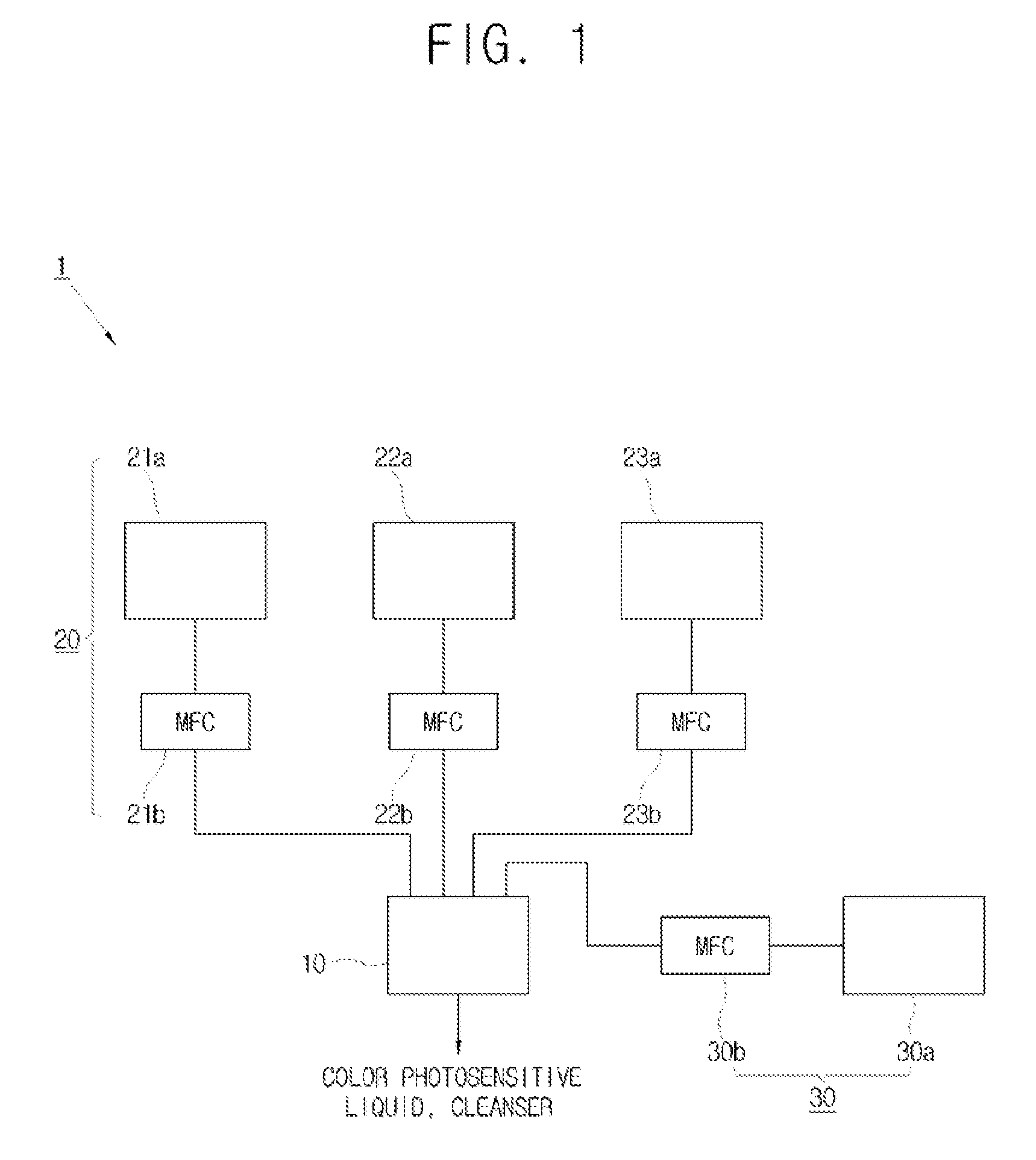

[0044]A slit coater according to an exemplary embodiment of the present invention will be described with reference to FIG. 1.

[0045]Referring to FIG. 1, a slit coater 1 comprises a slit nozzle 10, a color photosensitive liquid supplier 20 and a cleanser supplier 30. The slit coater 1 may further comprise a driver which allows the slit nozzle 10 to move on a plane.

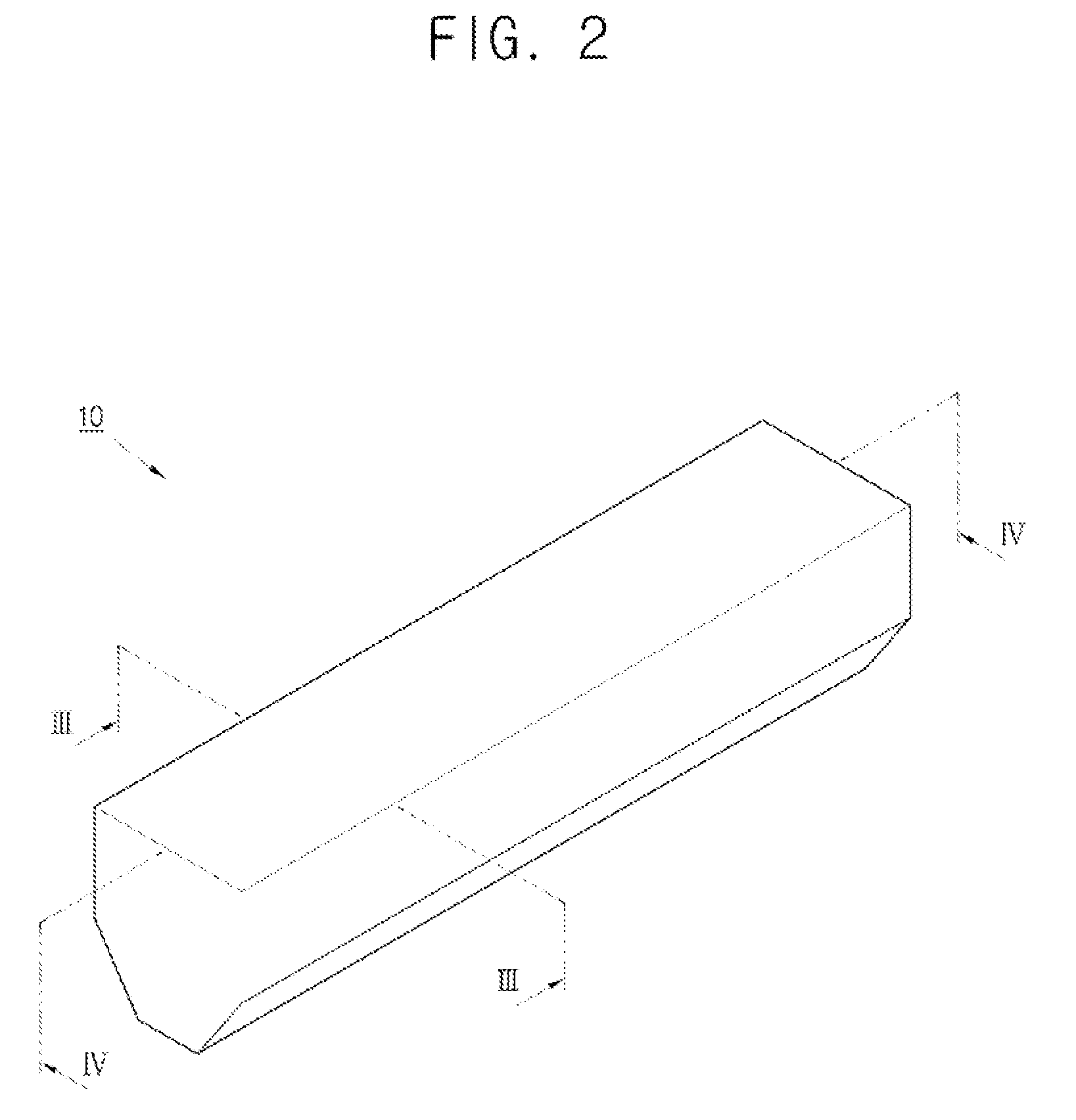

[0046]The slit nozzle 10 is supplied with color photosensitive liquid from the color photosensitive liquid supplier 20 and discharges the supplied color photosensitive liquid on a substrate. The slit nozzle 10 will be described in further detail later herein.

[0047]The color photosensitive liquid supplier 20 comprises three color photosensitive liquid tanks 21a, 22a and 23a and mass flow controllers 21b, 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap