Packaged device and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

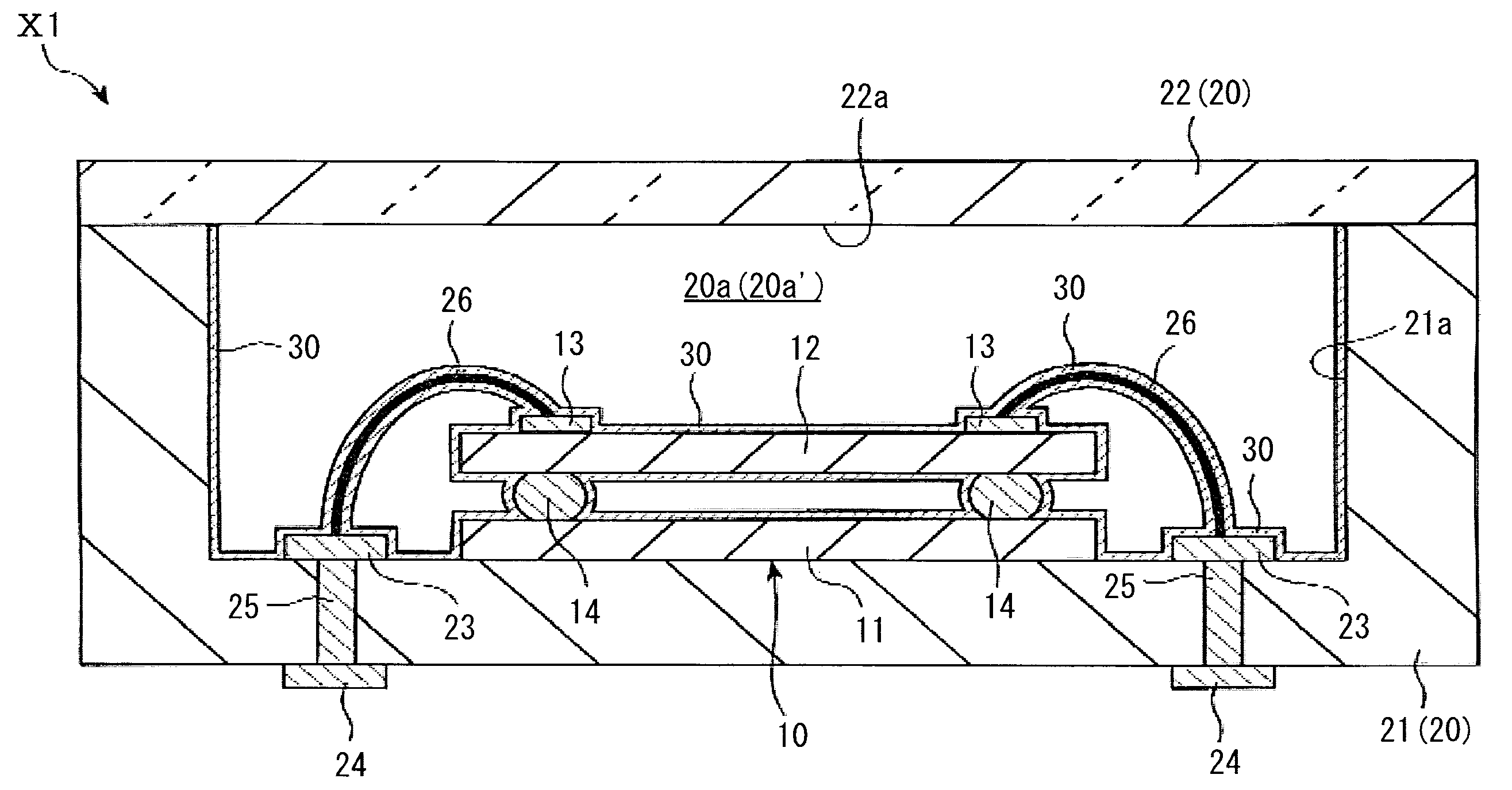

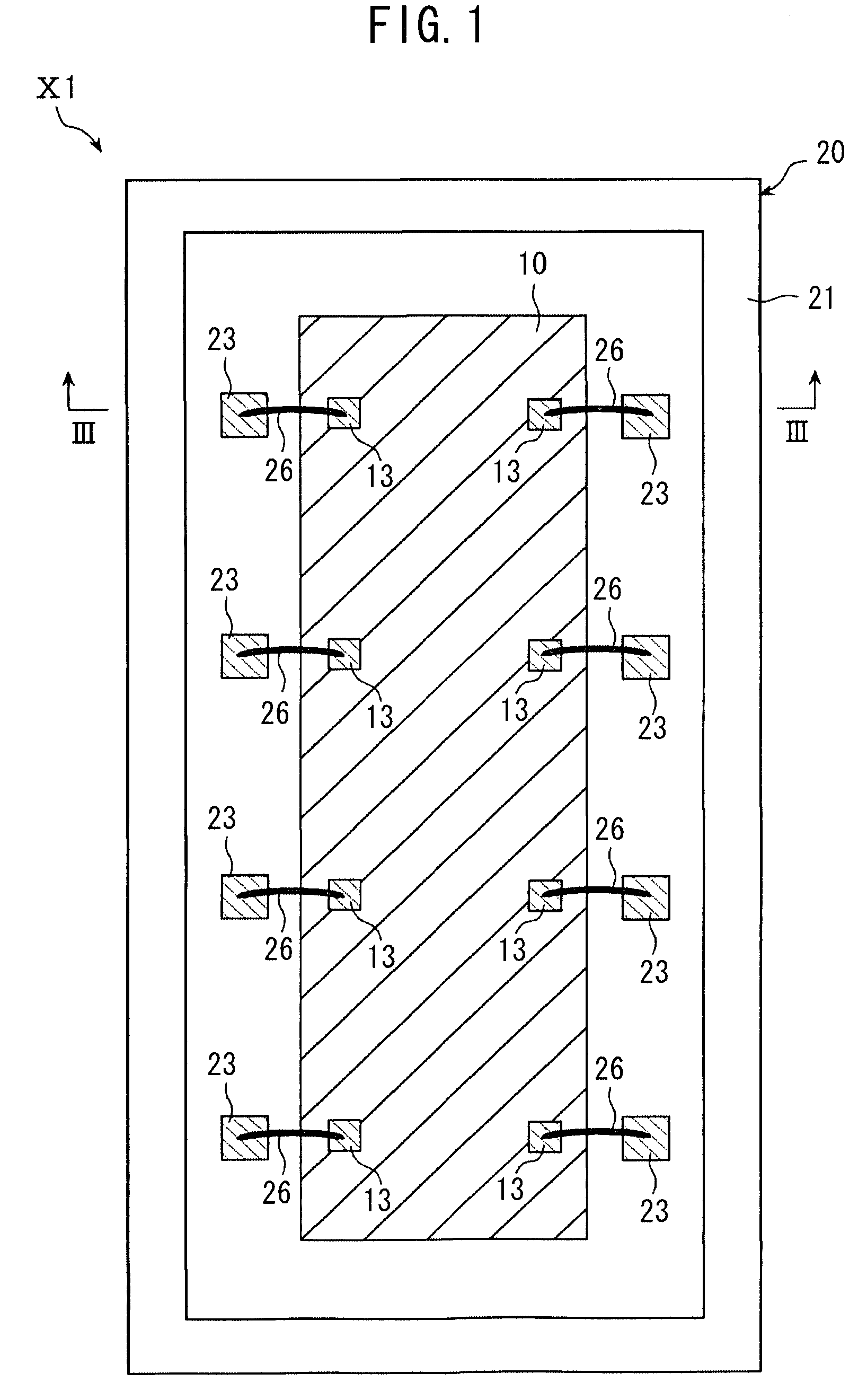

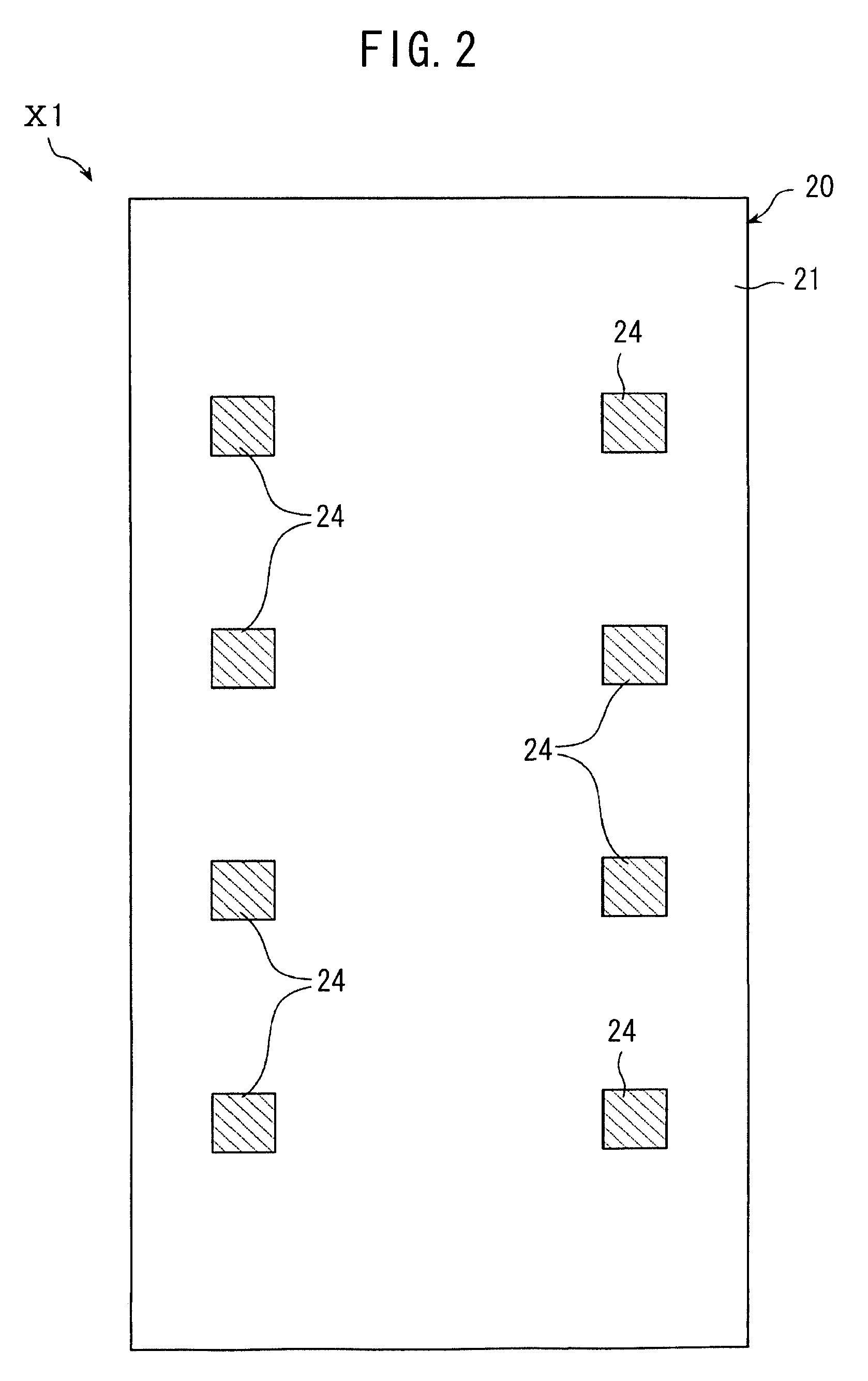

[0029]FIGS. 1 to 3 show a packaged device X1 according to a first aspect of the present embodiment. FIG. 1 is a (partly omitted) plan view of the packaged device X1. FIG. 2 is another plan view of the packaged device X1. FIG. 3 is a sectional view of the packaged device taken along line III-III in FIG. 1.

[0030]The packaged device X1 includes a device chip 10, a package 20, and a parylene film 30 (not shown in FIG. 1).

[0031]In the present aspect, the device chip 10 is what is called a MEMS mirror device. The device chip 10 includes a base substrate 11, a mirror substrate 12, and electrode pads 13. The base substrate 11 and the mirror substrate 12 are joined together via bumps 14. A plurality of micro mirror elements (not shown in FIGS. 1 and 3) are formed in the mirror substrate 12. The plurality of micro mirror elements are formed by processing an SOI (Silicon On Insulator) substrate by a MEMS technique.

[0032]FIG. 4A shows a micro mirror element Y formed in the mirror substrate 12. The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap