Passive mixer having transconductance amplifier with source degeneration capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]This description of the exemplary embodiments is intended to be read in connection with the accompanying drawings, which are to be considered part of the entire written description.

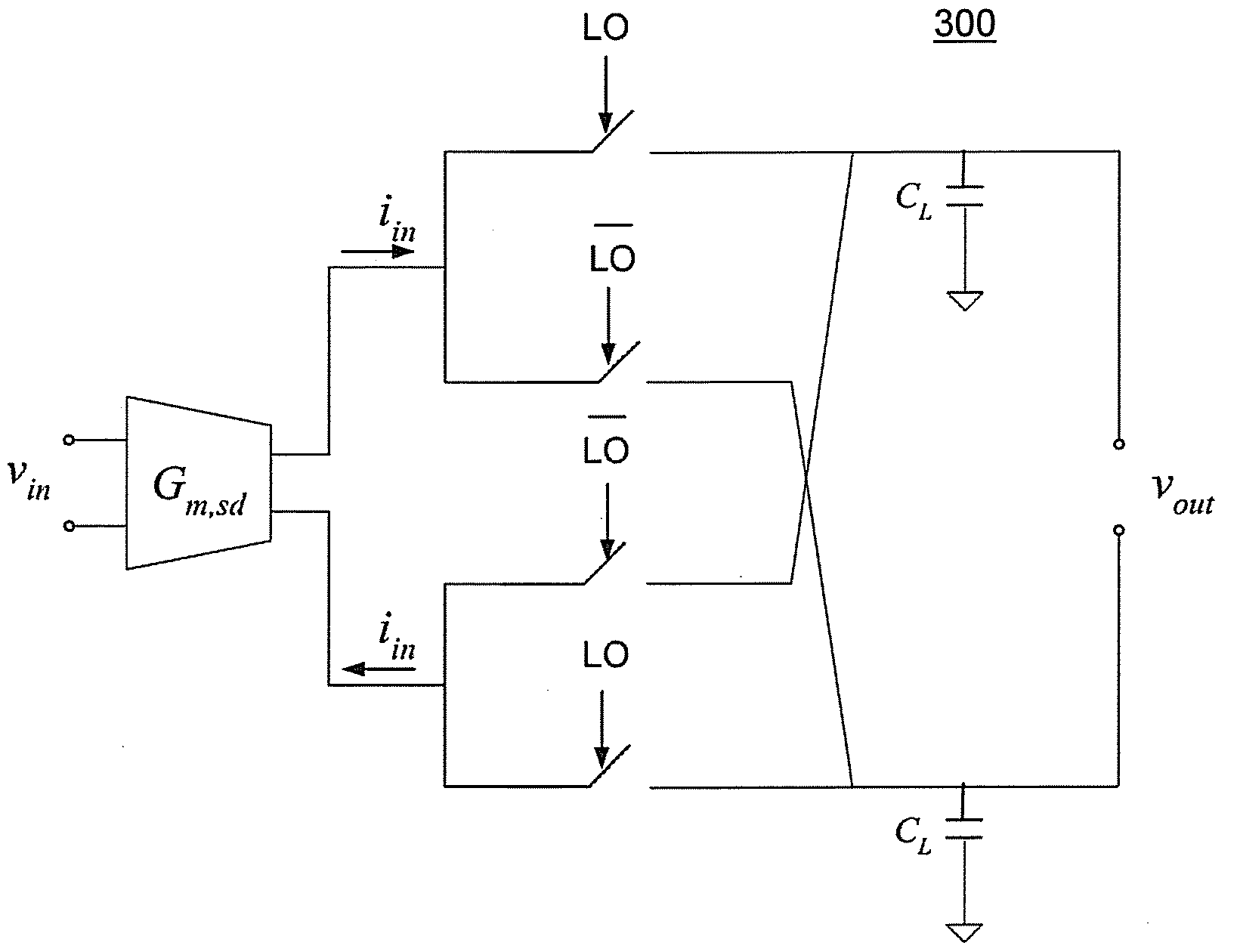

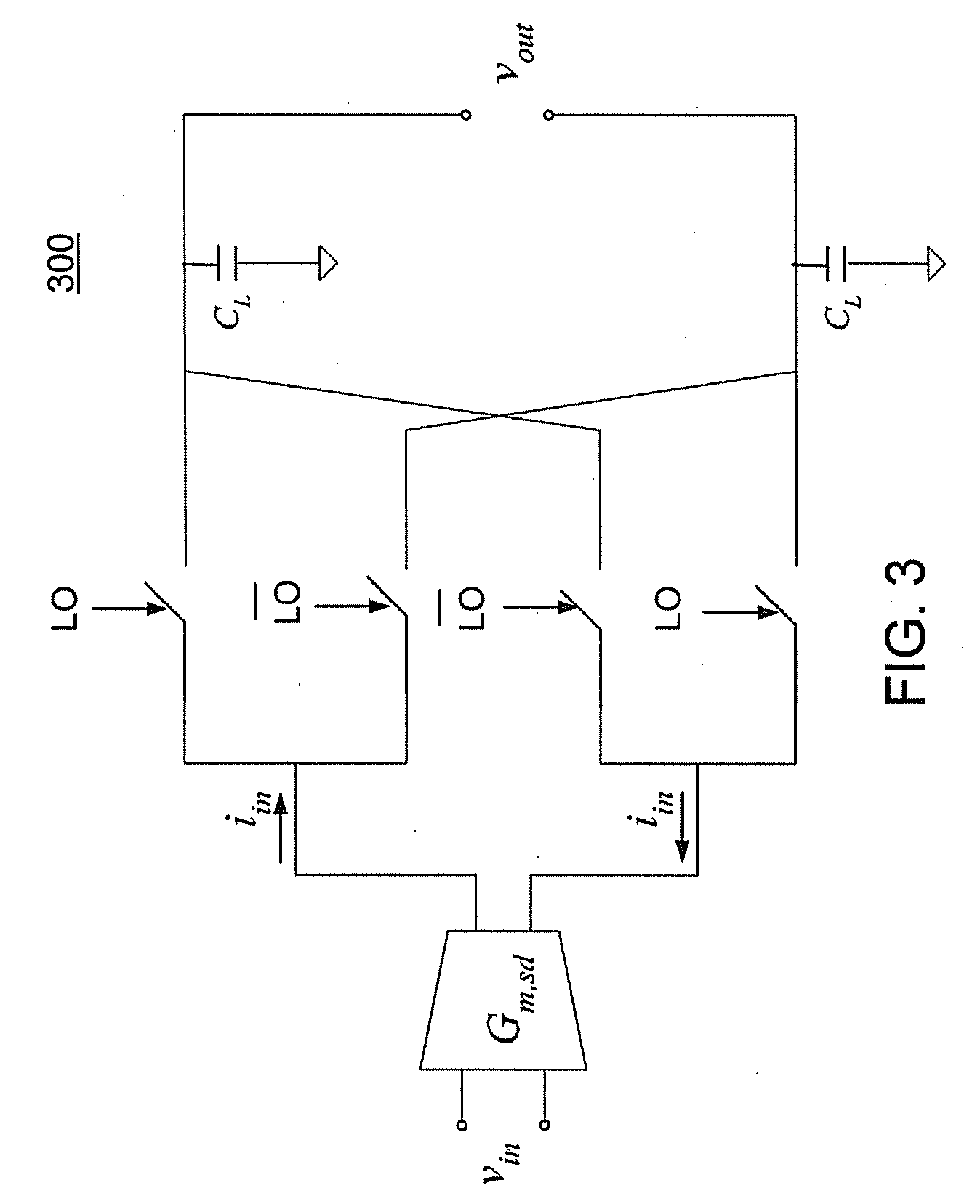

[0026]A current-mode passive mixer 300, 800, 900 with conversion gain that is independent of process, voltage, and temperature (PVT) variation is described below, with reference to FIGS. 3-9. Optionally, the conversion gain may be programmable. Using this technique, the conversion gain of the current-mode passive mixer 300, 800, 900 is proportional to the ratio of the source degeneration capacitance CS to the load capacitance CL. Thus, although the absolute capacitance and other circuit parameters vary with PVT, the ratio of the source degeneration capacitance CS to the load capacitance CL is independent of PVT variation, and so is the mixer conversion gain. In particular, if CS and CL are of the same type of construction, then both are assured to vary in the same manner together in response to any ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap