LED unit and LED module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

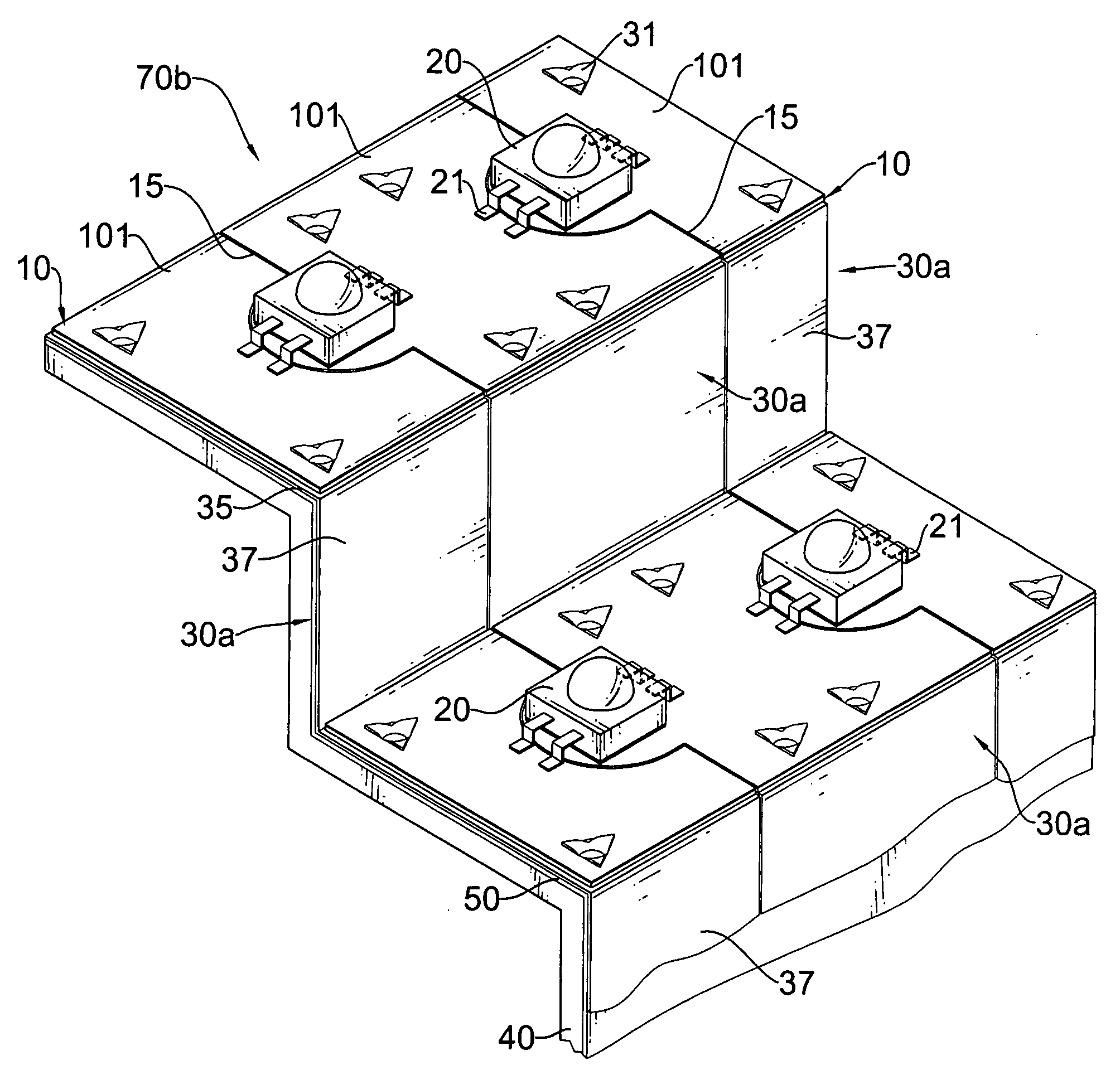

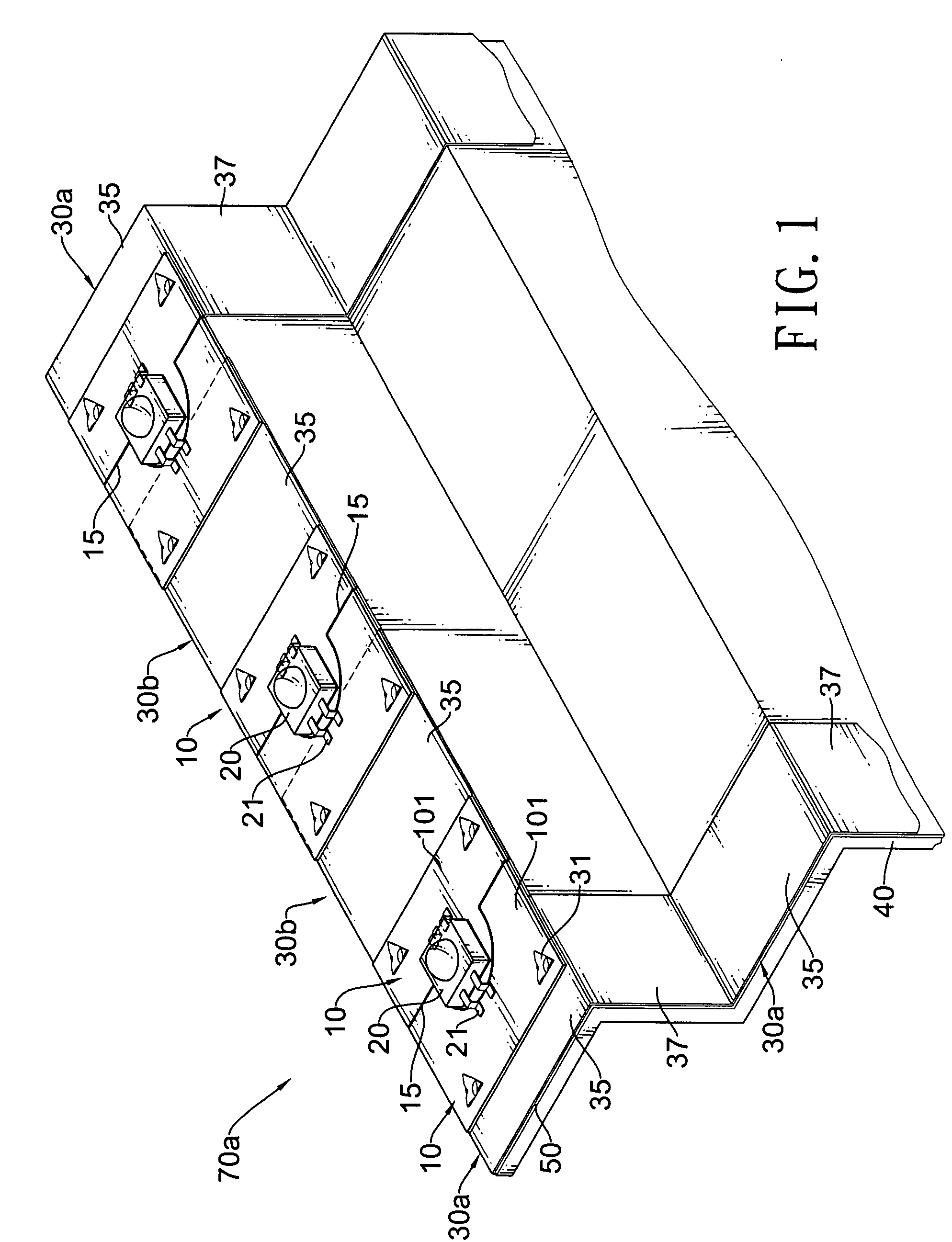

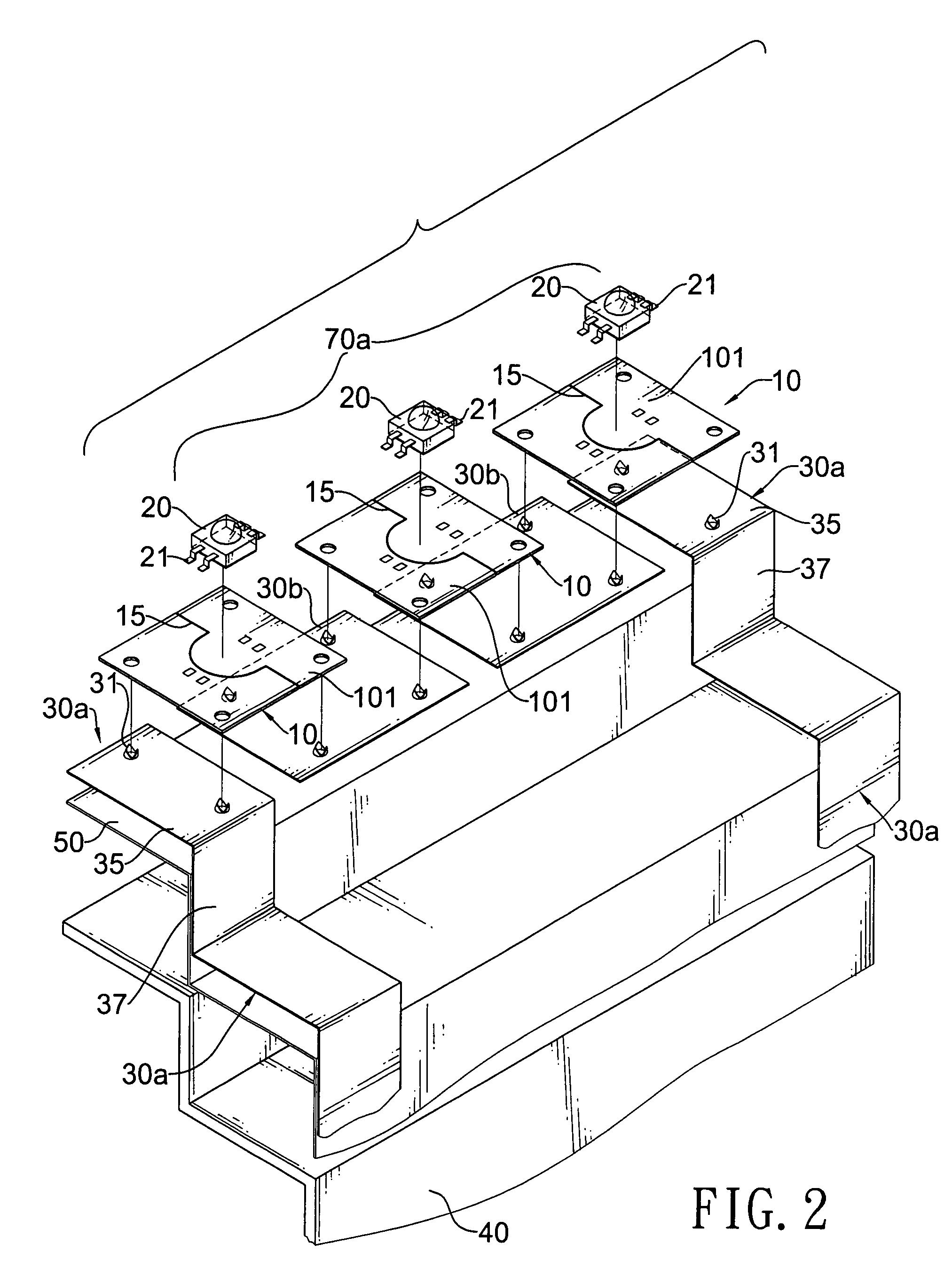

[0018]With reference to FIGS. 1, 2 and 3A, the LED module (70a) comprises multiple LED units (60). Each LED unit (60) comprises a pair of substrates, an LED (20), a pair of brackets (30a, 30b) and may further have a heat sink (40) and a heat-sink insulation layer (50).

[0019]The substrates (10, 10a), being electrically conductive, are separated from each other by a gap (15) and serves respectively as positive and negative electrodes. Each substrate (10, 10a) may further have a base and an insulation layer (101) and multiple mounting holes (102).

[0020]The base, being electrically conductive, has an outer surface and an inner surface. The inner surface is opposite to the outer surface. A first variant of the base is a copper base (103) formed into a single piece. With further reference to FIGS. 3B, a second variant of the base is laminated and has an aluminum board (106) and a copper board (105). The copper board (105) is attached to he aluminum board (106).

[0021]The insulation layer (101

second embodiment

[0026]In a second embodiment, both the brackets (30a) of each LED units (60) are 3D brackets, as shown in FIGS. 4 and 5.

[0027]The 3D bracket of each LED unit (60), being non-flat, may be stepped, inclined or curved, is mounted one of the substrates (10, 10a), may be mounted on adjacent substrates (10, 10a). The 3D brackets of the LED units (60) are connected integrally to one another to form at least one 3D bracket module being non-flat, serving as at least one positive or negative electrode and holding a number of the LEDs (20). Each 3D bracket module is connected to some of the LEDs (20). In the first embodiment, two 3D brackets are arranged on opposite sides of the LED modules (70a). In the second embodiments, three 3D brackets are arranged in the LED modules (70b). Semi-finished 3D bracket modules may be a flat board manufactured by a single processing. Furthermore, the semi-finished 3D bracket modules are further formed into finished 3D bracket modules with different configuration

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap