Laminated Glass with Shade Band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

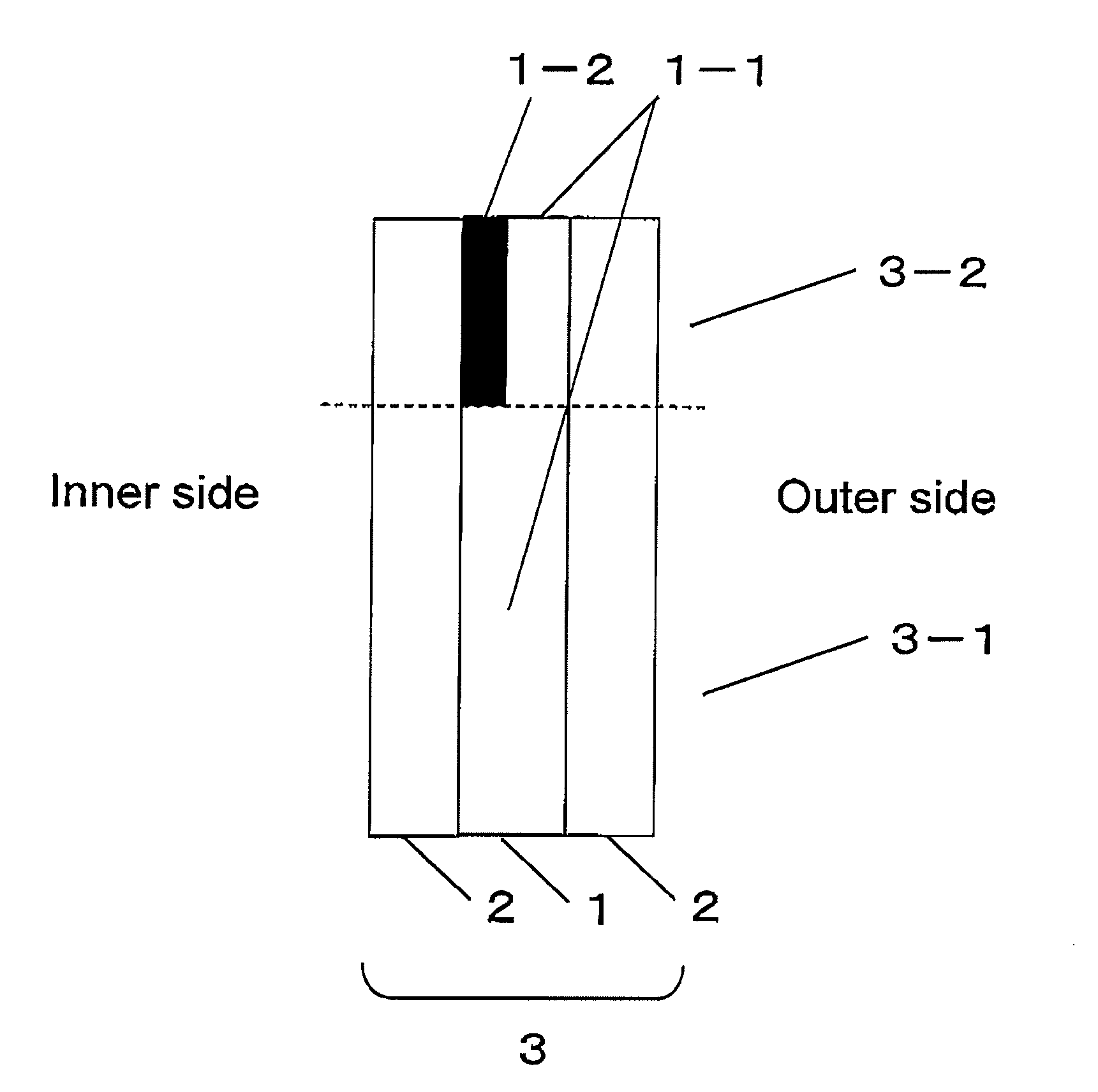

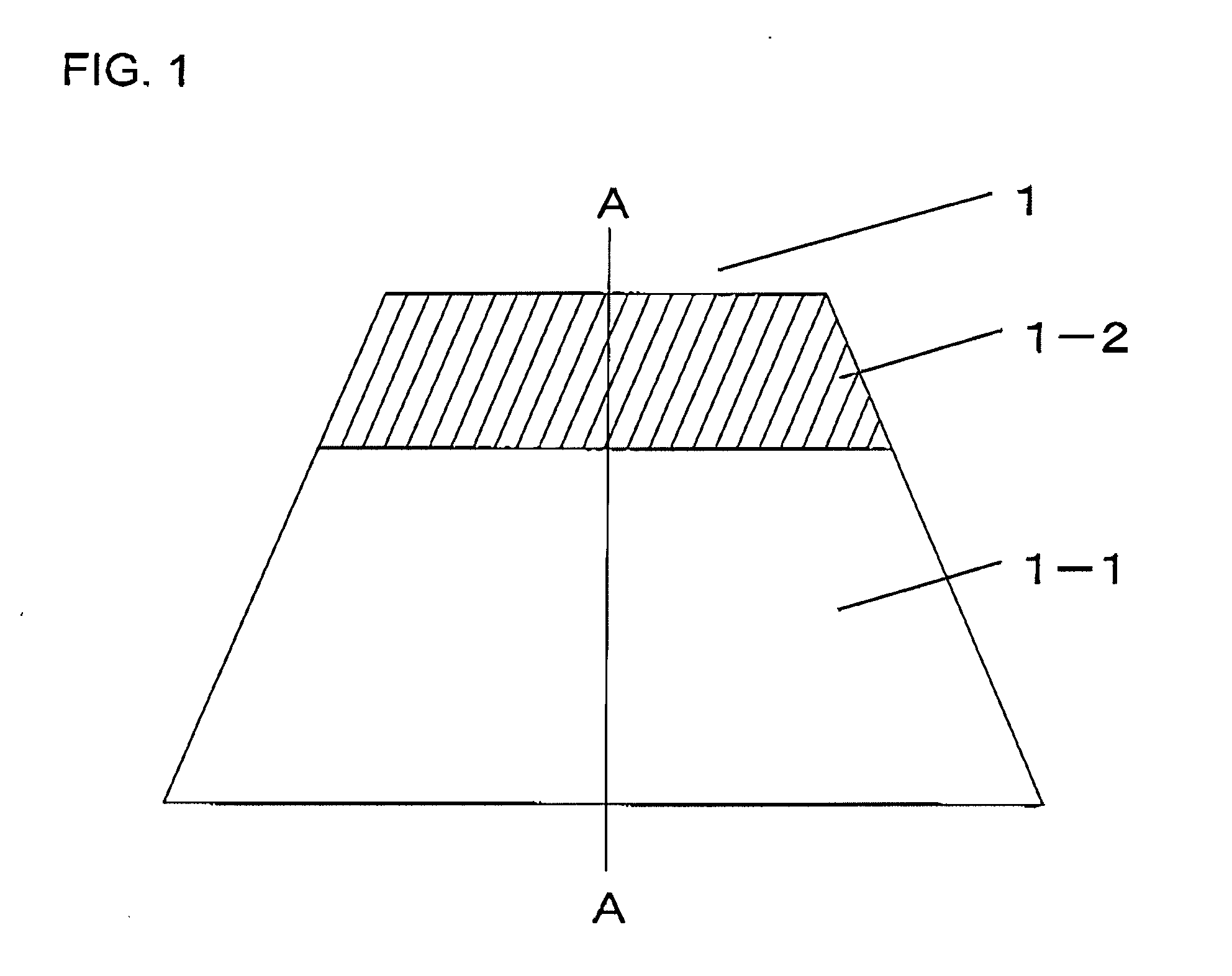

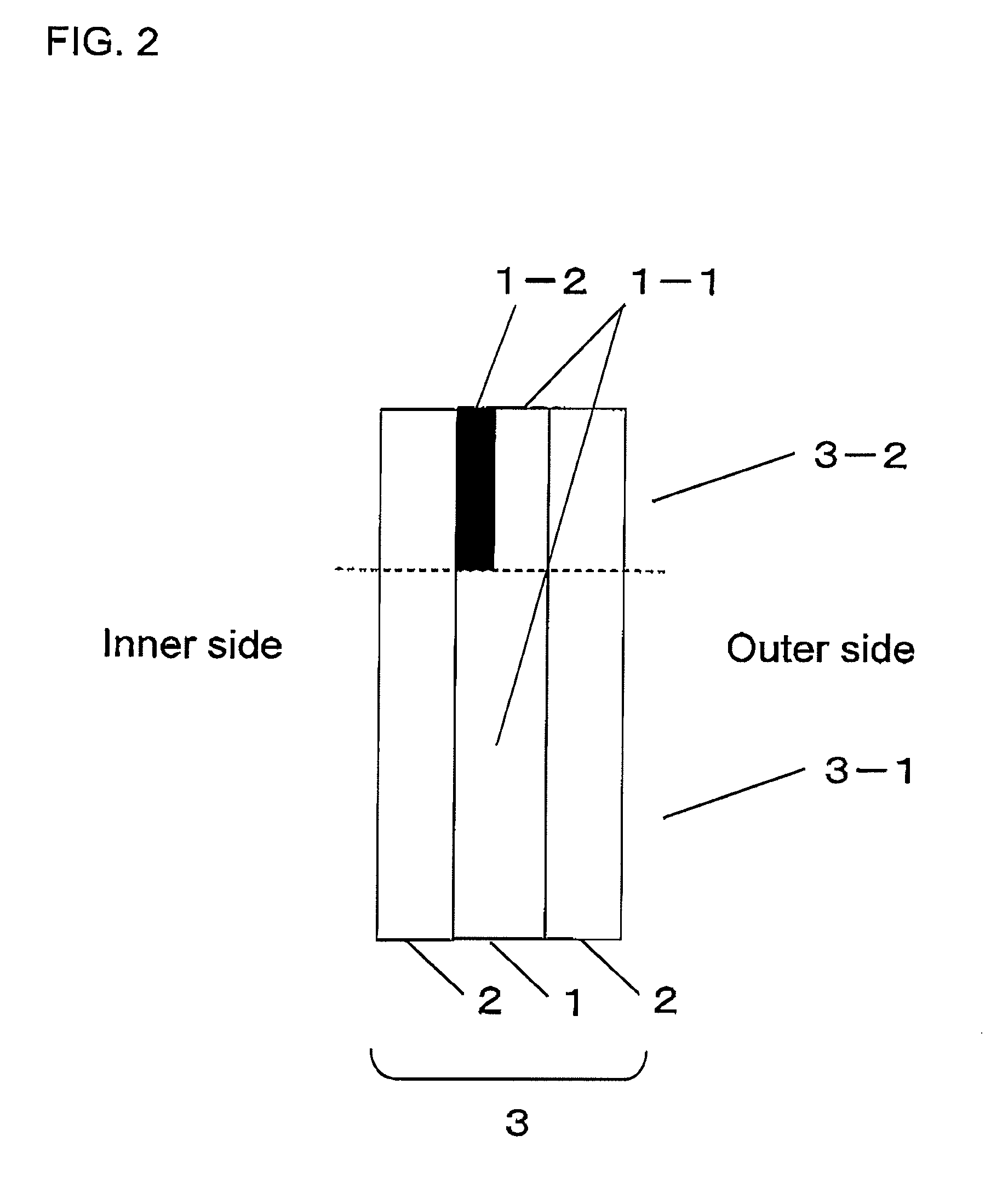

[0074]A belt-like region of a rectangular piece of intermediate film (thickness: 0.76 mm) (Saflex, product of Solutia Japan) along a longer side was colored green by use of a dye. The thus-colored piece was employed as an intermediate film for laminated glass.

[0075]Two rectangular green glass sheets (thickness: 2.1 mm) were stuck together with the mediation of the above-produced intermediate film for laminated glass. Sticking of the two glass sheets by use of the intermediate film was performed through the aforementioned conventional technique.

[0076]The light transmittance of the thus-produced laminated glass (first and second regions) was measured by means of a spectrophotometer UV 3100 PC (Shimadzu Corporation) over a wavelength range of 300 to 1,800 nm. FIG. 1 shows the results. Furthermore, visible light transmittance and light transmittance with respect to light beams (wavelengths: 700, 750, 875, and 1,000 nm) were also measured. The results are shown in FIG. 5 and Table 1.

example 2

[0077]The procedure of Example 1 was repeated, except that clear glass sheets were used instead of the green glass sheets employed in Example 1, to thereby produce a laminated glass.

[0078]The measurement was performed in a manner similar to that of Example 1, and the results are shown in FIG. 6 and Table 1.

example 3

[0079]The procedure of Example 1 was repeated, except that the thickness of the green glass sheets was changed from 2.1 mm to 2.3 mm, and an intermediate film (S-LEC, product of Sekisui Chem. Co., Ltd.) was colored by a dye to form a blue band, to thereby produce a laminated glass.

[0080]The measurement was performed in a manner similar to that of Example 1, and the results are shown in FIG. 7 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap