Mounting apparatus and mounting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

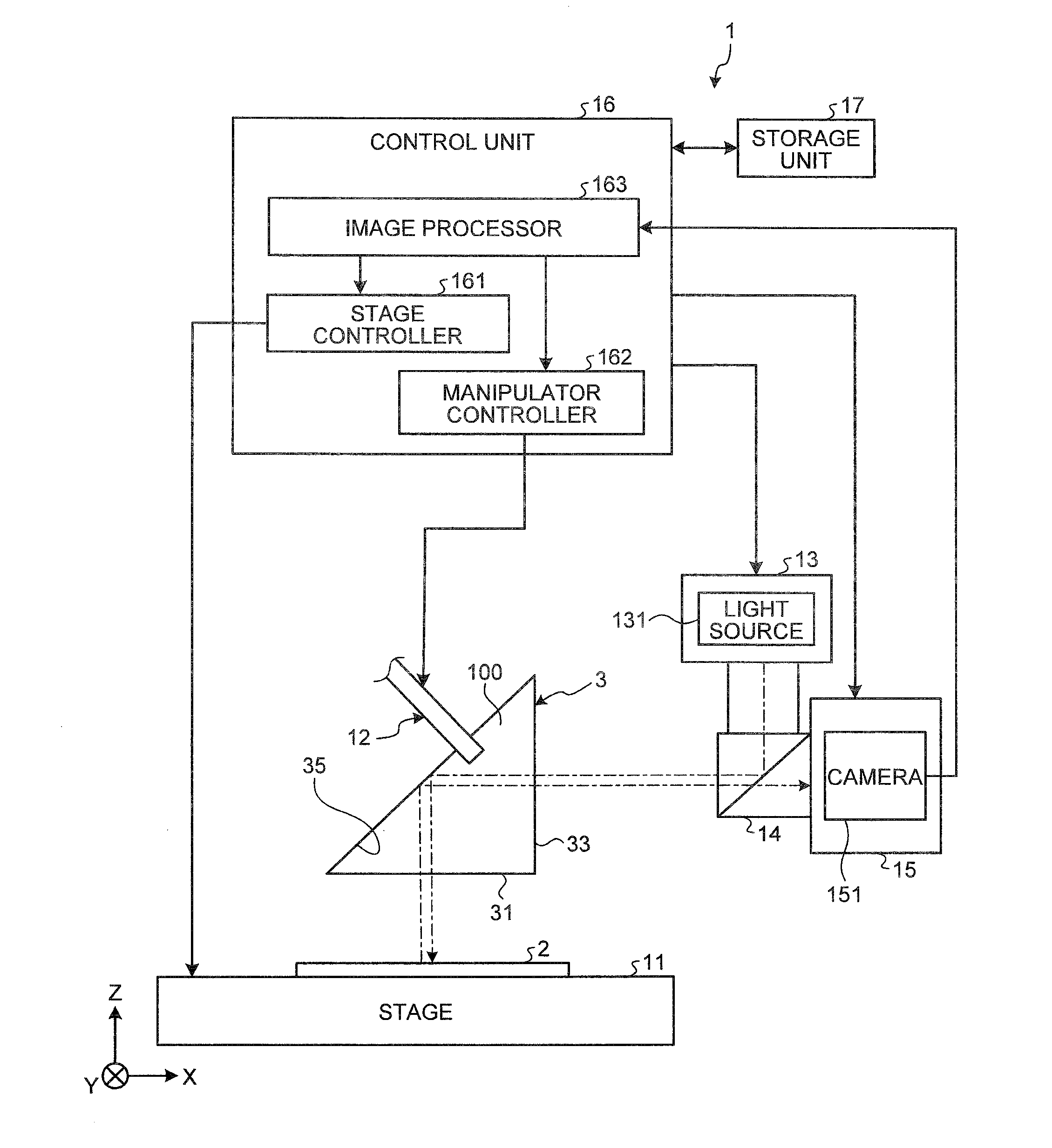

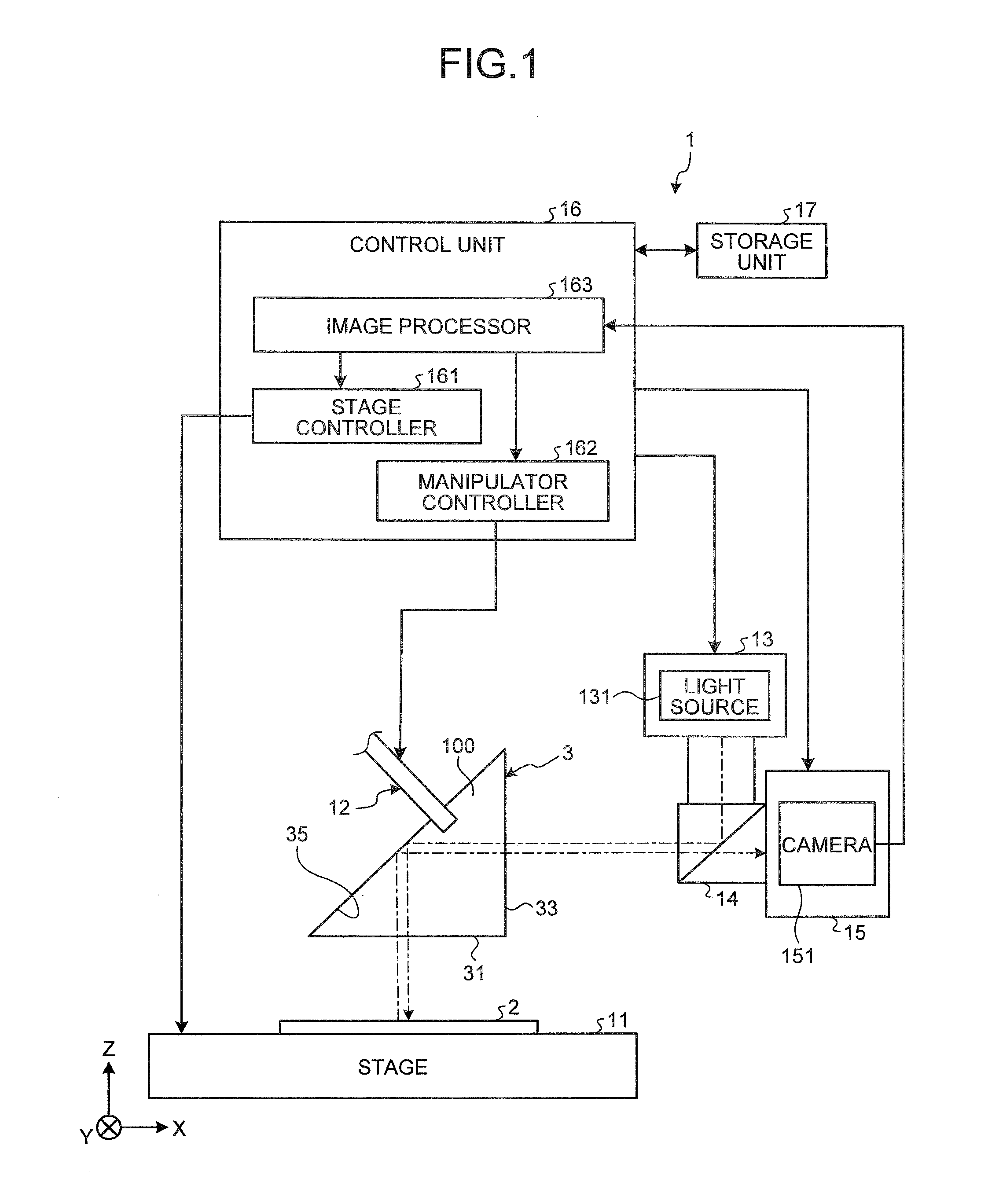

[0023]In a first embodiment of the present invention, a prism is illustrated as an optical component that refracts incident light and then sends out the incident light. A mounting apparatus that mounts the prism on a substrate that is provided with an alignment mark is illustrated as well. FIG. 1 is a schematic diagram illustrating an overall configuration of a mounting apparatus 1 according to the first embodiment. As depicted in FIG. 1, the mounting apparatus 1 includes a stage 11 on which a substrate 2 is mounted; a manipulator 12 that transfers a prism 3, an example of an optical component, that is mounted on the substrate 2; a light source unit 13; an optical path splitter 14; and an imaging unit 15.

[0024]The prism 3 that is held by the manipulator 12 is mounted on the substrate 2 later. Light from the side of the substrate 2 is incident on the prism 3. The prism 3 includes a first surface (hereinafter, “light going-out surface”) 31 that serves as a surface from which light incide

second embodiment

[0056]FIG. 10 is a schematic diagram illustrating an overall configuration of a mounting apparatus 1b of a second embodiment of the present invention. Parts like those of the first embodiment are denoted by like reference numerals. As illustrated in FIG. 10, the mounting apparatus 1b includes a light source unit 13-2 including a light source 131-2, an optical path splitter 14-2, and an imaging unit 15-2 including a camera 151-2, which are arranged above the stage 11, in addition to the light source unit 13, the optical path splitter 14, and the imaging unit 15 for capturing an image of the light incident surface 33 of the prism 3. The optical unit 13-2, the optical path splitter 14-2, and the imaging unit 15-2 can be realized using a configuration like that of the light source unit 13, the optical path splitter 14, and the imaging unit 15.

[0057]The optical unit 13-2, the optical path splitter 14-2, and the imaging unit 15-2 are used for capturing an image of the prism 3 from the side o

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap